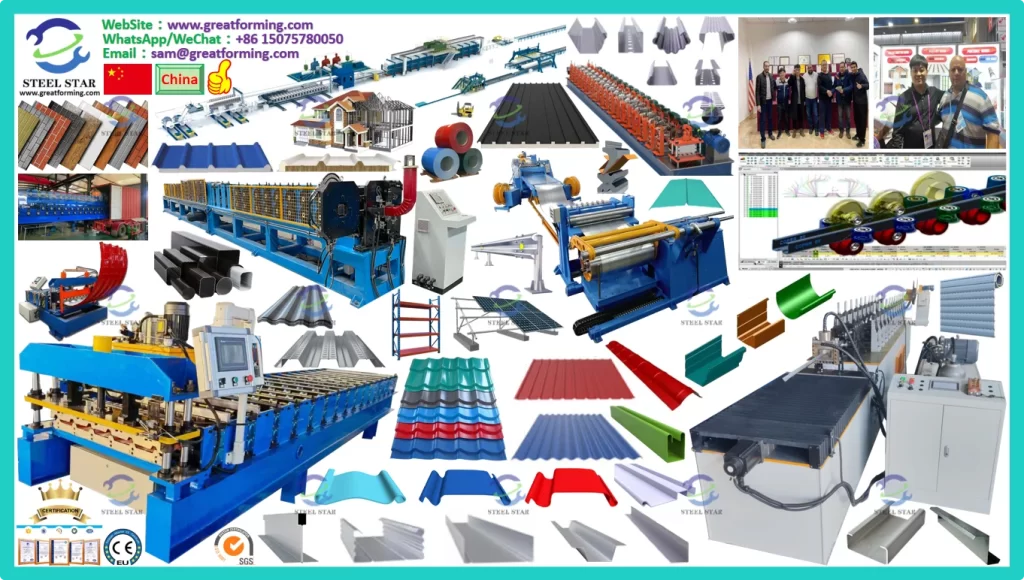

A Fully Automatic C/Z Purlin Integrated Roll Forming Machine is a specialized industrial machine used in the construction industry for the automatic production of C and Z-shaped purlins, which are structural components often used in the framework of buildings. These machines combine roll forming technology with automation to efficiently produce high-quality purlins with minimal human intervention.

Key Features:

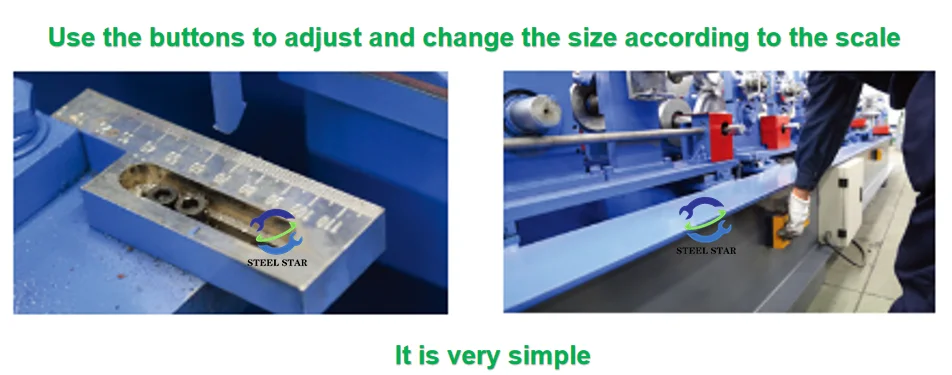

- Interchangeable Production: These machines can switch between C and Z profiles with minimal manual adjustments, often through automated controls.

- Roll Forming Process: The machine gradually shapes flat metal strips (usually steel or aluminum) into C or Z profiles through a series of rollers.

- Fully Automatic Operation: Modern versions are equipped with computerized control systems (PLC) for fully automated cutting, punching, and forming processes.

- Customization: It can produce purlins of different sizes and thicknesses, offering flexibility for various construction needs.

- High Efficiency: These machines are designed for high-speed, continuous production, which significantly reduces labor costs and time.

- Hydraulic Cutting and Punching: Equipped with hydraulic systems to cut and punch holes in the purlins as per specifications.

- Servo Motor Driven: Advanced machines often use servo motors for precise control over the roll forming process, ensuring consistent quality.

Benefits:

Ease of Use: The machine’s user-friendly interface and controls make it easier to operate even for non-expert users.

Cost-Effective: The automation reduces labor costs and minimizes errors, ensuring consistent product quality.

Versatility: Can be used in a variety of construction projects, including industrial and commercial buildings.

High-Speed Production: Increases production efficiency, ideal for large-scale construction projects.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)