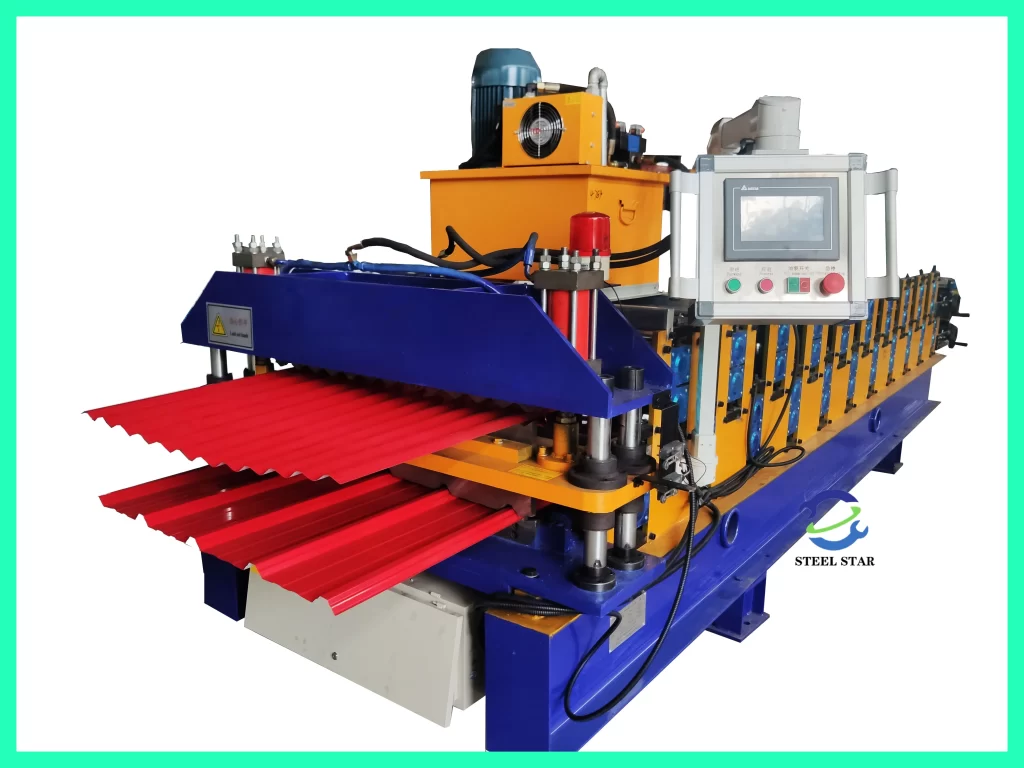

The terms Double Layer Roof Sheet Roll Forming Machine, Double Layer Roof Machine, and Double Model Roof Sheet Machine generally refer to the same category of equipment, which is designed for efficient production of roofing sheets in multiple profiles. Here’s an overview of these machines, highlighting their similar functions:

Overview:

These machines are engineered to streamline the production of metal roofing sheets by enabling the formation of two different profiles in a single unit. This dual-functionality is crucial for manufacturers needing to switch between styles without interrupting production or using additional space.

Key Characteristics:

Dual-Profile Capability: The machine features two roll forming lines stacked vertically. This design allows users to produce two different types of roofing sheets, such as trapezoidal and corrugated profiles.

Space Efficiency: The compact structure saves space compared to housing two separate machines for different profiles.

Applications:

Commonly used for the production of metal roof and wall panels in construction projects, including residential, commercial, and industrial buildings.

Ideal for facilities that manufacture roofing sheets in multiple designs, catering to varying aesthetic and structural needs.

Advantages:

Cost-Effective: Reduces capital investment by providing two functionalities in one machine.

High Productivity: Capable of producing large volumes of roofing sheets quickly.

Customizable: Can be tailored to meet specific requirements, such as different sheet widths or thicknesses.

Versatile: Works with a variety of metals, including galvanized steel, aluminum, and pre-painted coils.

Double Layer Roof Sheet Roll Forming Machine Video:

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)