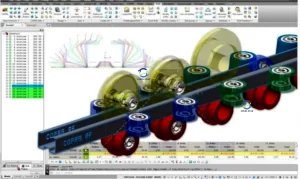

Roll forming is a type of rolling that involves continuously bending long strips of metal sheet (typically coiled steel) into the desired cross-section. Design the mold shape and number of groups according to the required size. The shrinkage ratio of each group of cold bending is different. Through cold bending group by group, the final desired size can be achieved. Combined with electronic control system, hydraulic system, shearing system and counting encoder to realize automated operation.

Technical Parameters :

- Raw material width : 30mm — 300mm (Can be customized according to your needs)

- Thickness of sheet : 0.2mm — 1.0mm (Can be customized according to your needs)

- speed : 10 m — 120 m/min (Can be customized according to your needs)

- Voltage : 380v 50hz 3phase / 220v 60hz 3phase (Can be customized according to your needs)

- Language : English / Spanish / Arabic / Russian / Portuguese / German / French (Can be customized according to your needs)

- Material of rollers : C45 / Gcr15 / Cr12 / Cr12 Mov (Can be customized according to your needs)

- Motor brand : Siemens / other (Can be customized according to your needs)

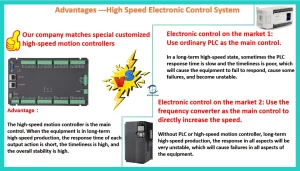

- Electronic control PLC : Siemens / Delta / other (Can be customized according to your needs)

- Number of roller rows: According to product design

If the speed reaches more than 70 meters/min, we use self-developed motion controller

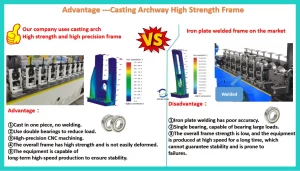

We structure and purchase integrated casting arch, non-welded, high strength and high precision frame

Application Scenarios :

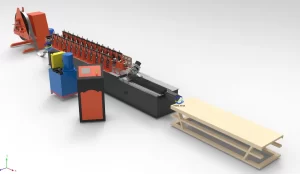

Equipment Production Line:

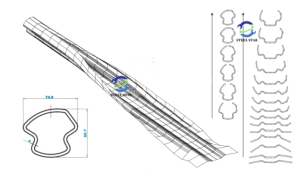

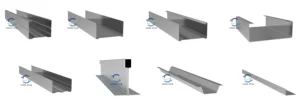

Related Product Layout Diagrams:

Keel is a building material used to support shapes and fix structures.

Keel is a building material used to support shapes and fix structures.

Widely used in hotels and terminals. Passenger terminals, stations, theaters, shopping malls, factories, office buildings, renovation of old buildings, interior decoration settings, ceilings and other places.

The keel is the skeleton and base material of decoration and is very commonly used. There are many types of keels. According to the different materials, they can be divided into wooden keels, light steel keels, aluminum alloy keels, steel keels, etc.

According to the use part, it can be divided into ceiling keel, vertical wall keel (partition wall keel), floor keel and hanging keel.

Depending on the decoration construction technology, there are also load-bearing and non-load-bearing keels (i.e., upper keels and non-upper keels).

Models are divided into:c type, u type, omega type, T type, triangle keel, etc.

advantage:

First, it should be waterproof and moisture-proof, otherwise the floor will be in direct contact with the floor and will easily rot. Second, it is easy to construct. If it is installed directly on the foundation, then the requirements for the foundation are quite strict.

The foundation must be made quite flat, otherwise it will not be easy to install. Moreover, if it is installed directly on the foundation, expansion screws are needed to fix it, which is not conducive to Beautiful. Third, the keel can be used to adjust the height difference accessories requirements.

Factory Information:

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)