Roll forming is a type of rolling that involves continuously bending long strips of metal sheet (typically coiled steel) into the desired cross-section.

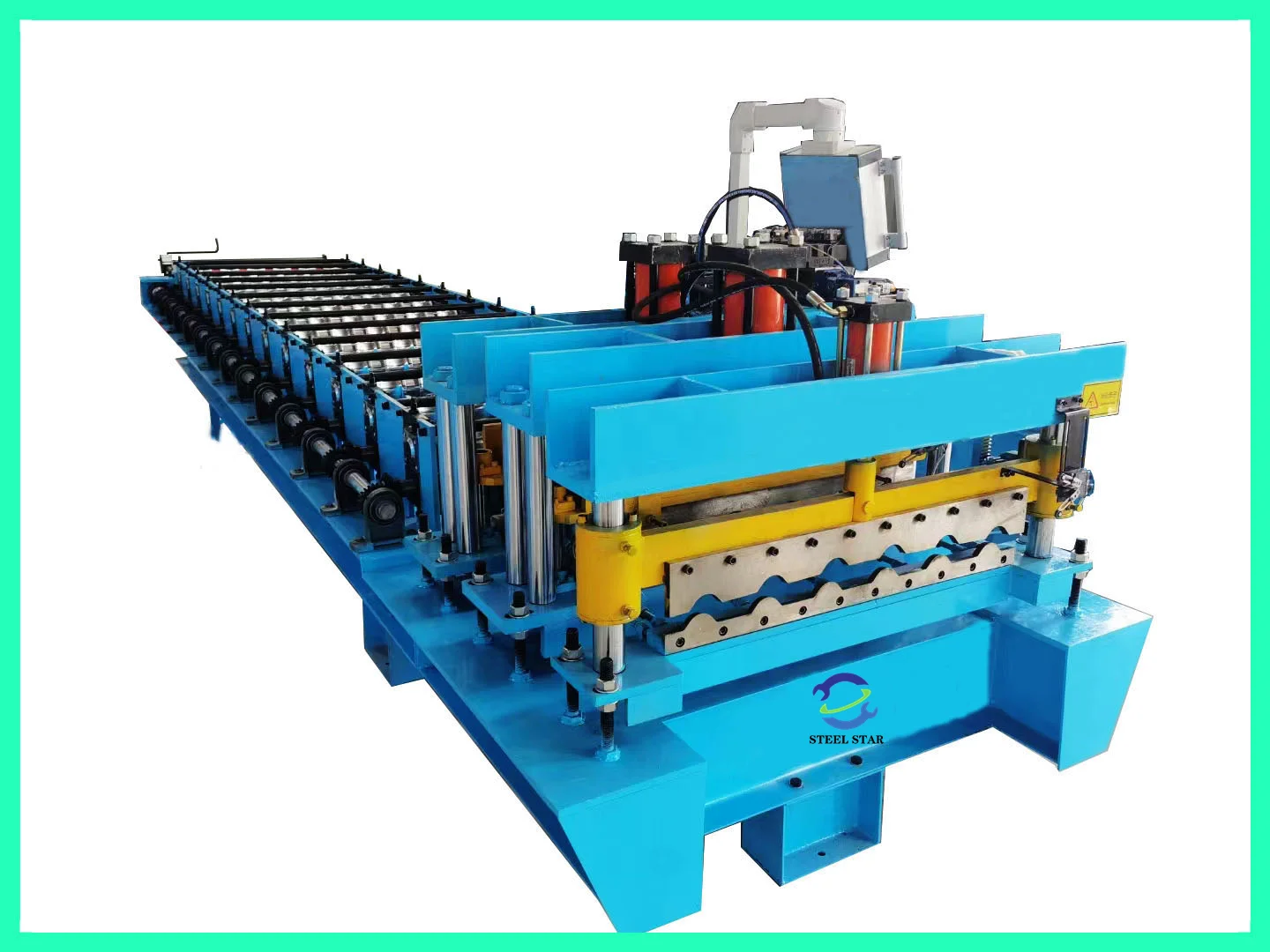

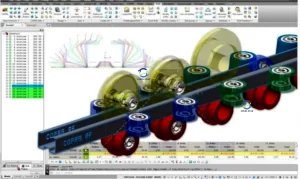

Design the mold shape and number of groups according to the required size. The shrinkage ratio of each group of cold bending is different. Through cold bending group by group, the final desired size can be achieved. Combined with electronic control system, hydraulic system, shearing system and counting encoder to realize automated operation.

Technical Parameters :

- Raw material width : 914mm / 925mm / 1000mm / 1200mm / 1220mm / 1250mm (Can be customized according to your needs)

- Thickness of sheet : 0.15mm — 1.0mm (Can be customized according to your needs)

- speed : 2 m — 8 m/min (Can be customized according to your needs)

- Voltage : 380v 50hz 3phase / 220v 60hz 3phase (Can be customized according to your needs)

- Language : English / Spanish / Arabic / Russian / Portuguese / German / French (Can be customized according to your needs)

- Material of rollers : C45 / Gcr15 / Cr12 / Cr12 Mov (Can be customized according to your needs)

- Motor brand : Siemens / other (Can be customized according to your needs)

- Electronic control PLC : Siemens / Delta (Can be customized according to your needs)

- Number of roller rows: According to product design

Application Scenarios :

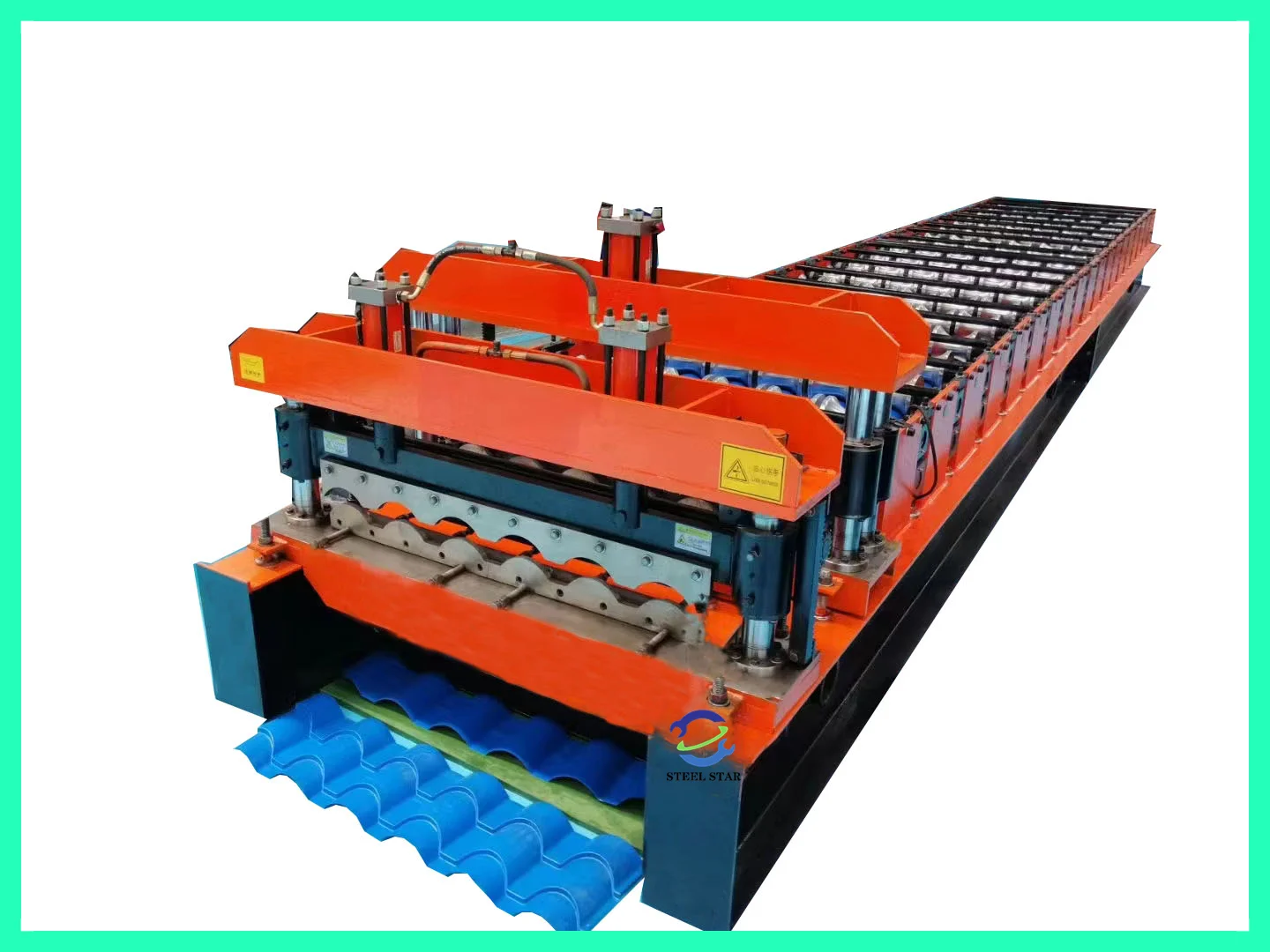

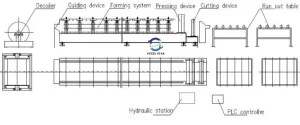

Equipment Production Line:

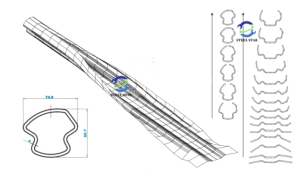

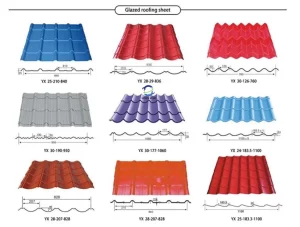

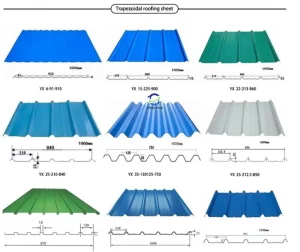

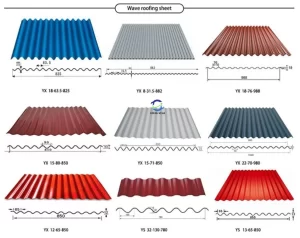

Related Product Layout Diagrams:

Antique colored steel glazed steel tiles are shaped like traditional ceramic glazed tiles, preserving the traditional beauty and reflecting the elegant classical beauty and traditional beauty of Chinese tiles. Base materials of various colors can be processed, including smooth, frosted, high-gloss, and diverse colors.

The material is light and the strength is high. The unit mass is only 1/10 of the terracotta tiles but it reaches a strength that cannot be achieved by terracotta tiles. The unique pressing design and the stamping depth that cannot be achieved in China make it stronger than domestic color steel tiles. Much higher. The plates of the product with a service life of up to 20 years are imported, and the surface has been treated with multiple anti-corrosion and anti-rust coatings to ensure the service life of the product. Excellent waterproofing The seamless connection of the slope surface, the interference combination of the entire tile, and the complete sealing and fixing components have waterproof properties that other building roof materials currently do not have. The roofing project can completely eliminate the need for waterproofing layer treatment. The construction time is short, the cost is reduced, the construction site requirements are met to the greatest extent, the construction intensity is reduced, and the construction efficiency is improved. Reduced installation costs. It has obtained four national patents and has been certified by the Intellectual Property Office of the People’s Republic of China for two utility model patents and two design patents.

Scope of application: villas, residential areas, hospitals, schools, civil buildings, garden pavilions, shopping malls, tourist attractions, public buildings, large-span steel structure houses, flat to slope, mobile homes, etc.

Product features: light weight, high strength, good waterproof performance, easy and quick installation.

Product application: urban flat to slope, villa roofs, scenic area buildings.

Factory Information:

# Glazed Tile Roof Sheet Roll Forming Machine,Glazed Tile Roll Forming Machine,Glazed Tile Forming Machine,Metal Glazed Tile Roll Forming Machine,High Speed Glazed Roof Tile Roll Forming Machine,Step Tiles Cold Roll Forming Machine,Glazed Step Tile Roll Forming Machine,Glazed Tile Roll Forming Machine For Sale From China Suppliers,China Glazed Tile Roof Sheet Roll Forming Machine,China Glazed Tile Roll Forming Machine,China Glazed Tile Forming Machine,China Metal Glazed Tile Roll Forming Machine,China High Speed Glazed Roof Tile Roll Forming Machine,China Step Tiles Cold Roll Forming Machine,China Glazed Step Tile Roll Forming Machine.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)