Roll forming is a type of rolling that involves continuously bending long strips of metal sheet (typically coiled steel) into the desired cross-section.

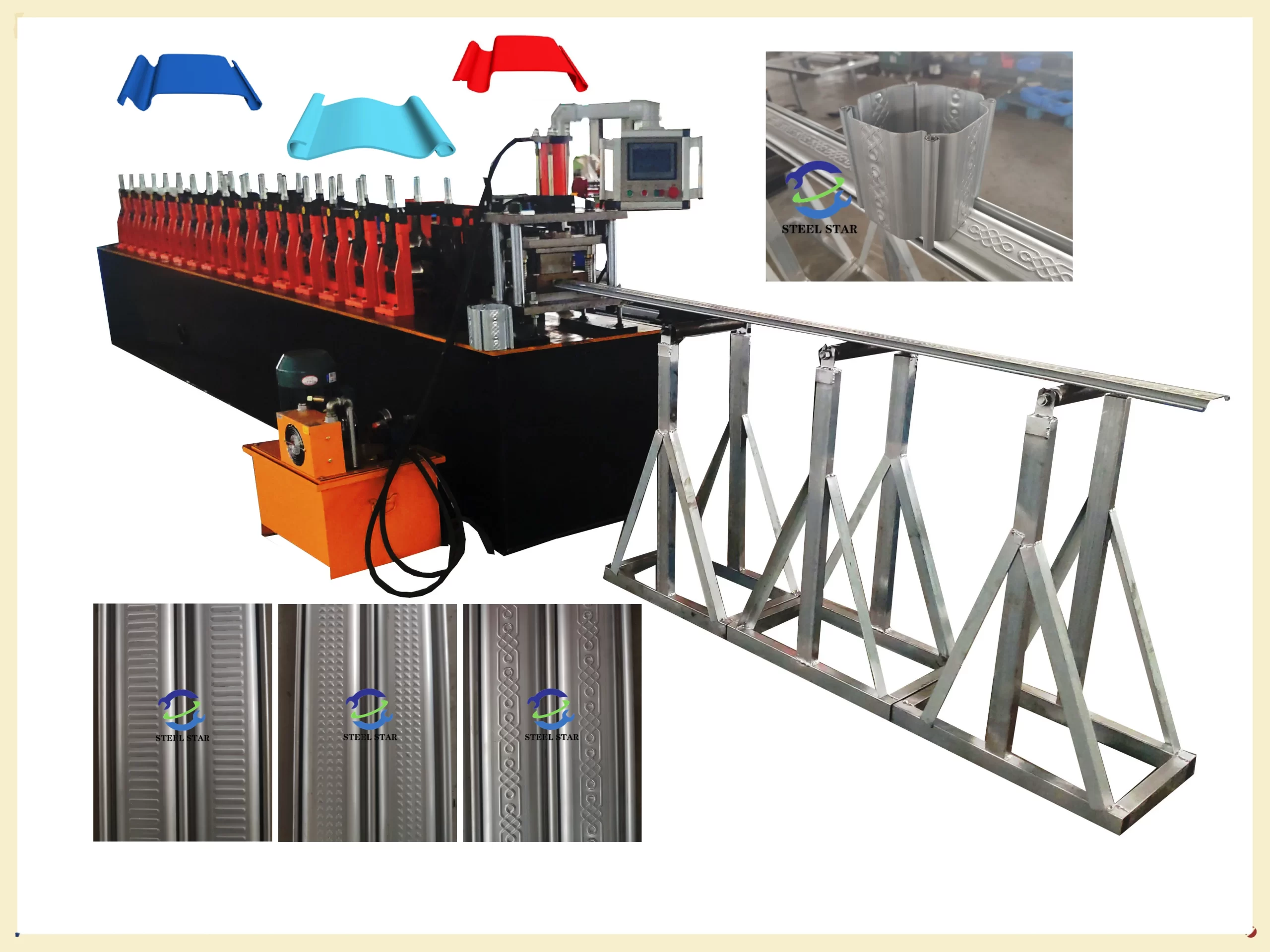

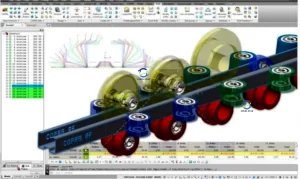

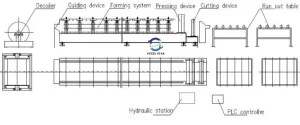

Design the mold shape and number of groups according to the required size. The shrinkage ratio of each group of cold bending is different. Through cold bending group by group, the final desired size can be achieved. Combined with electronic control system, hydraulic system, shearing system and counting encoder to realize automated operation.

Technical Parameters :

- Raw material width : 100mm — 300mm (Can be customized according to your needs)

- Thickness of sheet : 0.5mm — 1.0mm (Can be customized according to your needs)

- speed : 10 m — 50 m/min (Can be customized according to your needs)

- Voltage : 380v 50hz 3phase / 220v 60hz 3phase (Can be customized according to your needs)

- Language : English / Spanish / Arabic / Russian / Portuguese / German / French (Can be customized according to your needs)

- Material of rollers : C45 / Gcr15 / Cr12 / Cr12 Mov (Can be customized according to your needs)

- Motor brand : Siemens / other (Can be customized according to your needs)

- Electronic control PLC : Siemens / Delta (Can be customized according to your needs)

- Number of roller rows: According to product design

Application Scenarios :

Equipment Production Line:

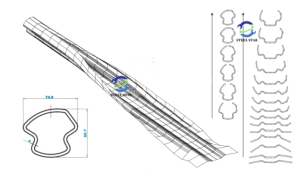

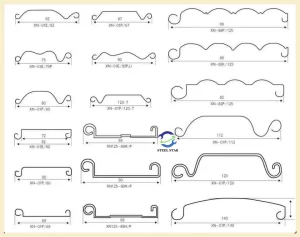

Related Product Layout Diagrams:

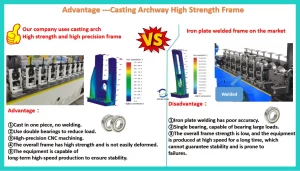

We structure and purchase integrated casting arch, non-welded, high strength and high precision frame

Rolling shutter doors are made of multi-jointed door panels connected in series. In a fixed slideway, the doors rotate up and down with the roller above the door as the center. Rolling shutter doors are usually widely used in shops.

Rolling shutter doors play the role of horizontal separation like walls. They are composed of curtain plates, seat plates, guide rails, supports, rollers, boxes, control boxes, rolling door machines, limiters, door lintels, manual quick-release switch devices, button switches and safety devices. They are generally installed in places where it is inconvenient to use walls for separation.

Function and characteristics :

The rolling door body is made of high-quality stainless steel and other materials, and is connected using the parallelogram principle, which is flexible and retractable. The driver is driven by a special motor, with a worm gear reduction, and a manual clutch, which can be opened and closed manually during a power outage. The rolling door is a telescopic shed type, with the characteristics of smooth opening and closing, transparent door body, and small space occupied after opening.

1. By setting up an intelligent infrared anti-climbing device, the system will immediately alarm when someone climbs the door, thereby ensuring the safety inside the door.

2. Special profiles: Adding different geometric shapes of tendons to high-hardness zinc-aluminum alloy profiles can greatly enhance its strength. The surface is treated with special electrophoresis, with unlimited gloss, not easy to stick to dust, not corroded by polluted gases, never rust, and long shelf life.

3. Engineering plastics: The main plastic parts of the door body (such as the connection between pipes, plastic parts, door body movable parts, etc.) are made of high-quality engineering plastics (such as PC, PA), which are high in toughness, impact-resistant, twist-resistant, wear-resistant, frost-resistant, sun-resistant, not easy to age, and have a long service life, free from the suffering of wind, snow, lightning, sun and rain.

4. Intelligent infrared probe anti-collision device: The door body can automatically return to run when encountering people or foreign objects 30-50cm during the closing process, thereby ensuring the safety of vehicles and pedestrians. Standard structure: The inner space of the door row (that is, the distance between the two adjacent curved main pipes, excluding the main pipe size) adopts the standard size of the rolling door 320mm (refer to foreign technology) to ensure that the cross pipe is the strongest and greatly reduce the running noise.

5. Unique process manufacturing The main frame profile of the door body is connected by plastic parts, and the screw fixation at the connection position adopts a hidden design to improve the appearance of the door body. The connection between the profile and the plastic parts adopts punching, pressing, drilling and other processes to make the door structure firm and without welding points. Cross connection design: The cross pipe is punched by a special process and equipped with a super PA wear-resistant sleeve. It is closely combined with the round pipe to not only make the door row structure more solid, but also ensure smoother operation.

6. Characteristics of rolling shutter doors Beautify the environment, improve the appearance of the enterprise, and enhance the corporate image; help to create a civilized enterprise, civilized factory, and civilized city atmosphere; improve safety, even if there is damage or climbing late at night, the alarm will be immediately sounded. Rolling shutter doors are mainly used in residential areas, schools, enterprises and institutions, etc.

Factory Information:

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)