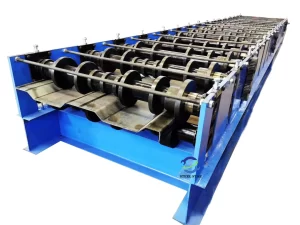

Roll forming is a type of rolling that involves continuously bending long strips of metal sheet (typically coiled steel) into the desired cross-section.

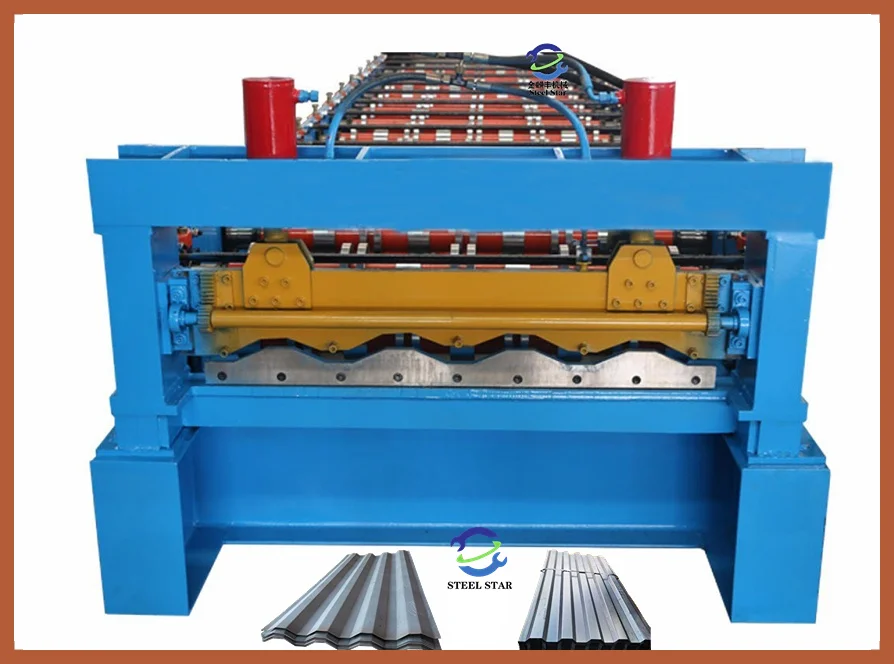

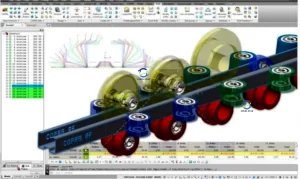

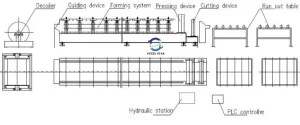

Design the mold shape and number of groups according to the required size. The shrinkage ratio of each group of cold bending is different. Through cold bending group by group, the final desired size can be achieved. Combined with electronic control system, hydraulic system, shearing system and counting encoder to realize automated operation.

Technical Parameters :

- Raw material width : 600mm / 1000mm / 1200mm / 1220mm / 1250mm (Can be customized according to your needs)

- Thickness of sheet : 1.0mm — 1.6mm (Can be customized according to your needs)

- speed : 10 m — 30 m/min (Can be customized according to your needs)

- Voltage : 380v 50hz 3phase / 220v 60hz 3phase (Can be customized according to your needs)

- Language : English / Spanish / Arabic / Russian / Portuguese / German / French (Can be customized according to your needs)

- Material of rollers : C45 / Gcr15 / Cr12 / Cr12 Mov (Can be customized according to your needs)

- Motor brand : Siemens / other (Can be customized according to your needs)

- Electronic control PLC : Siemens / Delta (Can be customized according to your needs)

- Number of roller rows: According to product design

Application Scenarios :

Equipment Production Line:

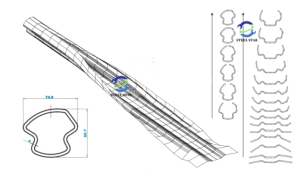

Related Product Information:

1. Material and characteristics of carriage plate

The material of carriage plate is a low-carbon steel plate used for carriage manufacturing. Its main characteristics are toughness, high strength, good ductility and other characteristics. In short, it is a durable plate made in the low-grade steel production process. During use, it not only has good wear resistance, but also has good surface quality, so the performance is guaranteed.

2. Application scope of carriage plate

Unlike some high-grade steel products, although the carriage plate is low-priced, it has a wide range of applications. It is one of the important materials for manufacturing various products. For example, it is widely used in the construction and manufacturing industries to manufacture low-requirement technical process components and parts, such as: manufacturing oil, natural gas, pipelines, cable supports, urban drainage systems, Hong Kong subway highway safety guardrails and light worms in agricultural machinery manufacturing, long-size parts and other manufacturing fields. In addition, there are more specific applications, including ships, offshore platforms, aerospace, vehicles, automobiles, chemicals, metallurgy, mining, oil transportation and other industries.

3. Market prospects of carriage plates

Although carriage plates are low-grade steel products, they are of high value in the current market. They have low production costs and good usability, so they are highly competitive in the market. In the future, market demand will continue to grow steadily, especially with the increase in China’s manufacturing output, the market prospects of carriage plates are brighter.

In summary, carriage plates are not scrap iron. Although their prices are relatively low, they have a wide range of applications and are tough and wear-resistant. Therefore, they have an important position and potential in the manufacturing industry.

Factory Information:

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)