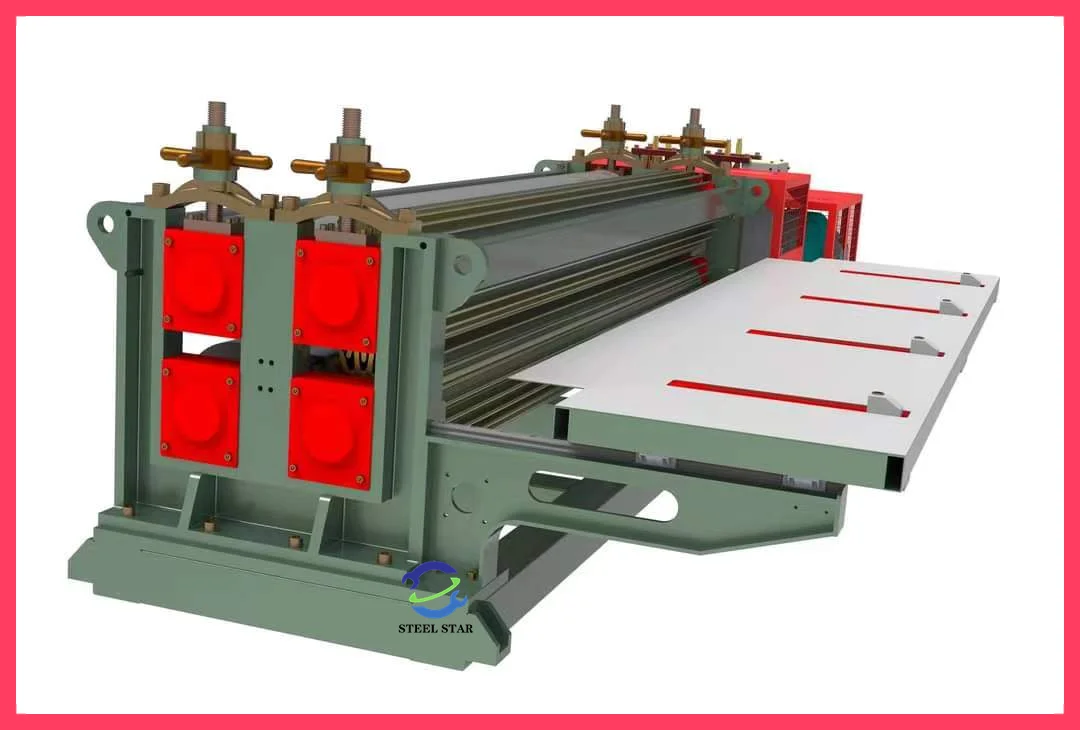

Roll forming is a type of rolling that involves continuously bending long strips of metal sheet (typically coiled steel) into the desired cross-section.

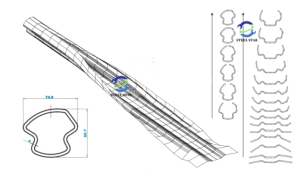

Design the mold shape and number of groups according to the required size. The shrinkage ratio of each group of cold bending is different. Through cold bending group by group, the final desired size can be achieved. Combined with electronic control system, hydraulic system, shearing system and counting encoder to realize automated operation.

Technical Parameters :

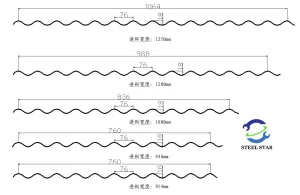

- Raw material width : 914mm / 940mm / 1000mm / 1200mm / 1220mm / 1250mm (Can be customized according to your needs)

- Thickness of sheet : 0.15mm — 0.4mm G550 (Can be customized according to your needs)

- speed : 10 m — 30 m/min (Can be customized according to your needs)

- Voltage : 380v 50hz 3phase / 220v 60hz 3phase (Can be customized according to your needs)

- Language : English / Spanish / Arabic / Russian / Portuguese / German / French (Can be customized according to your needs)

- Motor brand : Siemens / other (Can be customized according to your needs)

- Machine can be customized in length:2 M / 2.5 M / 3 M / 3.5 M / 4 M / 4.5 M / 5M / 6M / 8M (Can be customized according to your needs)

Application Scenarios :

Related Product Information:

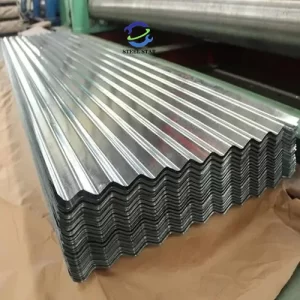

This barrel corrugated roll forming machine has high precision and produces high-strength plate G550 material with a thickness of 0.15-0.4mm without deformation.

This high-strength plate thin material arc roof plate has low cost and high strength, and is used most in South Africa and Africa.

Machine can be customized in length :2M — 8M.

The machine uses production technology: you can put them into the machine one by one, or you can put 2 sheets together into the machine to improve efficiency.

Factory Information:

# Barrel Corrugated Roll Forming Machine,Barrel Corrugated Machine,Barrel Corrugated Sheet Metal Roll Forming Machine,Corrugated Sheet Roll Forming Machine,Barrel Corrugated Roof Sheet Making Machine,G550 Barrel Corrugation Machine,Barrel Type Corrugated Roof Forming Machine.Thin thickness 0.12-0.3mm barrel corrugated roll forming machine is using for thin galvanized coil.This barrel type corrugation machine or barrel corrugated sheet machine is capable to produce corrugated sheets from 0.12-0.3mm thickness.Barrel Corrugated Roofing Sheet Machine, Barrel Corrugated Roof Sheet Making Machine .corrugated machines,zinc sheet making machine barrel type roofing,Barrel corrugation metal sheet roll forming machine,Africa Market Barrel Corrugated Sheet Forming Machine is a kind of roofing sheet roll forming machine for making roofing panel sheet,China Barrel Corrugated Roll Forming Machine,China Barrel Corrugated Machine,China Barrel Corrugated Sheet Metal Roll Forming Machine,China Corrugated Sheet Roll Forming Machine,China Barrel Corrugated Roof Sheet Making Machine,China G550 Barrel Corrugation Machine,China Barrel Type Corrugated Roof Forming Machine.China Thin thickness 0.12-0.3mm barrel corrugated roll forming machine is using for thin galvanized coil.China this barrel type corrugation machine or barrel corrugated sheet machine is capable to produce corrugated sheets from 0.12-0.3mm thickness.China Barrel Corrugated Roofing Sheet Machine, China Barrel Corrugated Roof Sheet Making Machine .China corrugated machines,China zinc sheet making machine barrel type roofing,China Barrel corrugation metal sheet roll forming machine,Africa Market China Barrel Corrugated Sheet Forming Machine is a kind of roofing sheet roll forming machine for making roofing panel sheet.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)