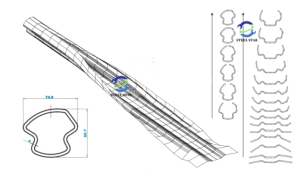

Roll forming is a type of rolling that involves continuously bending long strips of metal sheet (typically coiled steel) into the desired cross-section.

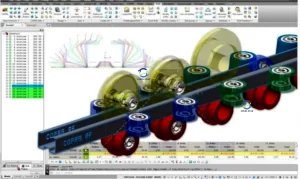

Design the mold shape and number of groups according to the required size. The shrinkage ratio of each group of cold bending is different. Through cold bending group by group, the final desired size can be achieved. Combined with electronic control system, hydraulic system, shearing system and counting encoder to realize automated operation.

Technical Parameters :

- Raw material width : 914mm / 925mm / 1000mm / 1200mm / 1220mm / 1250mm (Can be customized according to your needs)

- Thickness of sheet : 0.15mm — 1.0mm (Can be customized according to your needs)

- speed : 2 m — 8 m/min (Can be customized according to your needs)

- Voltage : 380v 50hz 3phase / 220v 60hz 3phase (Can be customized according to your needs)

- Language : English / Spanish / Arabic / Russian / Portuguese / German / French (Can be customized according to your needs)

- Material of rollers : C45 / Gcr15 / Cr12 / Cr12 Mov (Can be customized according to your needs)

- Motor brand : Siemens / other (Can be customized according to your needs)

- Electronic control PLC : Siemens / Delta (Can be customized according to your needs)

- Number of roller rows: 2 -5 Rows

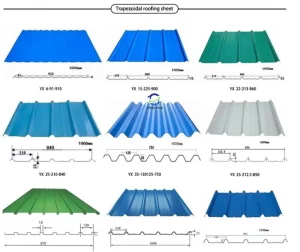

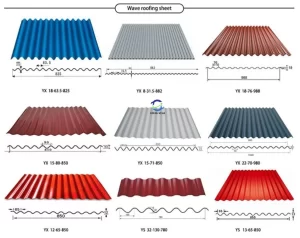

Application Scenarios :

Related Product Layout Diagrams:

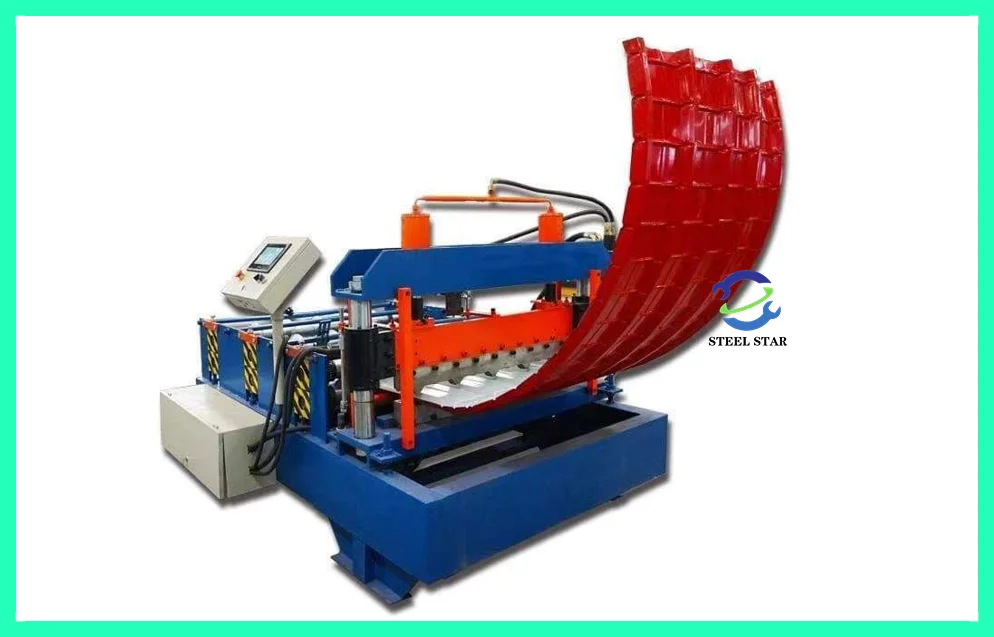

The steel arching machine is a device used to produce the arch plate on the top of the workshop building. The equipment has the advantages of simple production, small footprint and high efficiency. The arching machine can only arch after pressing, so its volume is very small, generally composed of only three rows or even two rows of shafts. The operation is very simple and the efficiency is very high.

The classification of arching machines is as follows:

According to its appearance, it can be divided into two types: vertical arching machine and horizontal arching machine. According to the production method, it can also be divided into gear arching and hydraulic arching.

The characteristics of the arching machine are as follows:

It has the characteristics of light weight, high strength, large load-bearing capacity and good seismic resistance, and is widely used in the field of multi-story steel structure buildings. No beams and no sandals, the space is tall and open, and it can be divided and combined at will, which is convenient to use.

Light weight, strong rigidity, good elasticity and excellent seismic performance.

Mechanical bite lock seam, airtight, time-saving and efficiency improvement.

Reasonable force mode, safe reserve, can withstand large wind loads and seismic forces.

Diverse design styles and strong adaptability, whether it is a bustling street or a remote town, economical, beautiful and applicable.

The hydraulic arching machine is a fully automatic machine for bending finished roof panels, which can meet the needs of curved and arched roof tiles.

The hydraulic arching machine can control the angle and speed of the finished product bending by adjusting parameters. Ensure the consistency and stability of the finished product quality.

Whether it is a simple straight arch or a complex curved arch, it can be easily achieved. Zhongtuo’s new hydraulic arching machine uses advanced technology, and the fixed blades are set against the beam instead of being set on the beam with screws.

Due to this new fixing method, the service life of the hydraulic arching machine blades can be extended by 3-5 years.

The hydraulic arching machine has been widely used in the roof tile arching industry. Its basic principle is simple, easy to operate, and has safety advantages such as saving time, controllable arching quality and simple operation.

Factory Information:

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)