Roll forming is a type of rolling that involves continuously bending long strips of metal sheet (typically coiled steel) into the desired cross-section.

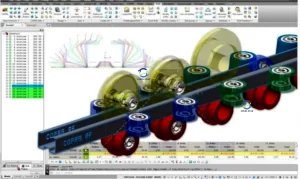

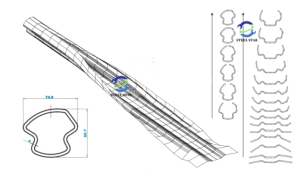

Design the mold shape and number of groups according to the required size. The shrinkage ratio of each group of cold bending is different. Through cold bending group by group, the final desired size can be achieved. Combined with electronic control system, hydraulic system, shearing system and counting encoder to realize automated operation.

Technical Parameters :

- Raw material width : 100mm — 500mm (Can be customized according to your needs)

- Thickness of sheet : 0.25mm — 1.0mm (Can be customized according to your needs)

- speed : 10 m — 100 m/min (Can be customized according to your needs)

- Voltage : 380v 50hz 3phase / 220v 60hz 3phase (Can be customized according to your needs)

- Language : English / Spanish / Arabic / Russian / Portuguese / German / French (Can be customized according to your needs)

- Material of rollers : Gcr15 / Cr12 / Cr12 Mov (Can be customized according to your needs)

- Motor brand : Siemens / other (Can be customized according to your needs)

- Electronic control PLC : Siemens / Delta / other (Can be customized according to your needs)

- Number of roller rows: According to product design

- Seam method : ① welding ② overlapping edge biting

Seam method (① welding):

Seam method (② overlapping edge biting):

Application Scenarios :

Equipment Production Line:

Application fields: widely used in machinery manufacturing, construction industry, metallurgical industry, agricultural vehicles, agricultural greenhouses, automobile industry, railways, highway guardrails, container frames, furniture, decoration and steel structure fields, etc.

Used in engineering construction, glass curtain walls, door and window decoration, steel structure, guardrails, machinery manufacturing, automobile manufacturing, home appliance manufacturing, shipbuilding, container manufacturing, electricity, agricultural construction, agricultural greenhouses, bicycle racks, motorcycle racks, shelves, fitness equipment, leisure and tourism products, steel furniture, various specifications of oil casing, oil pipes and pipeline pipes, water, gas, sewage, air, heating and other fluid transportation, fire fighting and brackets, construction industry, etc.

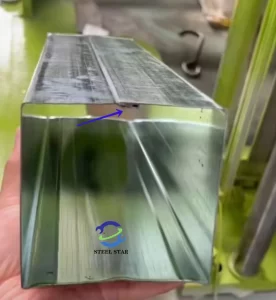

1. Structural characteristics and material differences between square tubes and round tubes

Square tubes and round tubes are both common metal tubes. They have certain differences in appearance, structure, and use.

Round tubes are a kind of hollow tubular material, the full name of which is “seamless steel tube”. Its cross section is circular, so it is called round tube. Round tube materials mainly include carbon steel, alloy steel, stainless steel, etc.

Square tubes, also known as square tubes and rectangular tubes, square tubes, as the name suggests, have a rectangular cross section. Square tube materials also include carbon steel, alloy steel, stainless steel, etc. In contrast, square tubes are more suitable for buildings or accessories with square structures, while round tubes are more suitable for parts in bends.

2. Comparison of the compressive strength of square tubes and round tubes

The strength and stiffness of square tube and round tube materials are not the same, and their compressive strength is also different.

The strength and compressive resistance of square tubes are better than those of round tubes. This is because the cross section of square tubes is rectangular, closed on all sides, and the distribution and projection area of steel on the cylinder are larger than those of round tubes, so that square tubes can better resist the extrusion of external forces. At the same time, the wall thickness of the square tube is relatively large, so the overall rigidity is relatively strong.

The round tube has excellent performance when bending because of its circular cross-section, and its deformation is small, and it can withstand greater forces. In the case of pressure deformation, the round tube has more advantages than the square tube.

In general, the use of square tubes and round tubes has certain legitimacy and rationality, and the comparison of compressive resistance needs to be selected according to the specific use environment and conditions.

3. Conclusion

In summary, square tubes and round tubes are both conventional metal pipes, and each has its own advantages. If you need to withstand huge external pressure, it is recommended to give priority to square tubes; if you need to consider the performance of bending and deformation, then round tubes are more suitable. It is necessary to choose according to the specific use environment and conditions to ensure that the appropriate pipe is selected.

Factory Information:

# Steel Pipe Making Machine,Pipe Making Machine,Pipe Welding Machine,Pipe Roll Forming Machine,Steel Pipe Cold Roll Forming Machine,Steel Pipe Roll Forming Machine,Welded Pipe Roll Forming Machine,Tube Mill Line & Pipe Mill Line,China Steel Pipe Making Machine,China Pipe Making Machine,China Pipe Welding Machine,China Pipe Roll Forming Machine,China Steel Pipe Cold Roll Forming Machine,China Steel Pipe Roll Forming Machine,China Welded Pipe Roll Forming Machine,China Tube Mill Line & Pipe Mill Line.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)