Technical Parameters :

- Raw material width : 914mm / 925mm / 1000mm / 1200mm / 1220mm / 1250mm / 1600mm (Can be customized according to your needs)

- Thickness of sheet : 0.15mm — 3.0mm (Can be customized according to your needs)

- speed : 10 m — 100 m/min (Can be customized according to your needs)

- Voltage : 380v 50hz 3phase / 220v 60hz 3phase (Can be customized according to your needs)

- Language : English / Spanish / Arabic / Russian / Portuguese / German / French (Can be customized according to your needs)

- Slitting blade material : Cr12 / Cr12 Mov (Can be customized according to your needs)

- Motor brand : Siemens / other (Can be customized according to your needs)

- Electronic control PLC : Siemens / Delta / other (Can be customized according to your needs)

- Raw material weight of unwinder and winder:5T / 7T / 8T / 10T /12T / 15T / 20T / 25T (Can be customized according to your needs)

Slitting machine, also known as slitting line, slitting machine, slitting machine, is a name for metal slitting equipment.

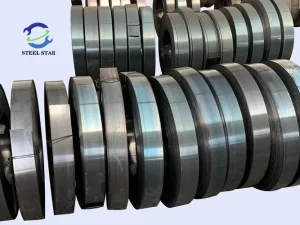

1. Purpose: Suitable for longitudinal shearing of metal strips and rewinding the slit narrow strips into coils.

2. Advantages: easy operation, high cutting quality, high material utilization, stepless speed regulation of cutting speed, etc.

3. Structure: It consists of unwinding (unwinding), material positioning, slitting longitudinal shearing, coiling (rewinding), etc.

4. Applicable materials: tinplate, silicon steel sheet, aluminum strip, copper, stainless steel plate, galvanized plate, etc.

5. Applicable industries: transformers, motors, home appliances, automobiles, building materials, packaging industry, etc.

Application Scenarios :

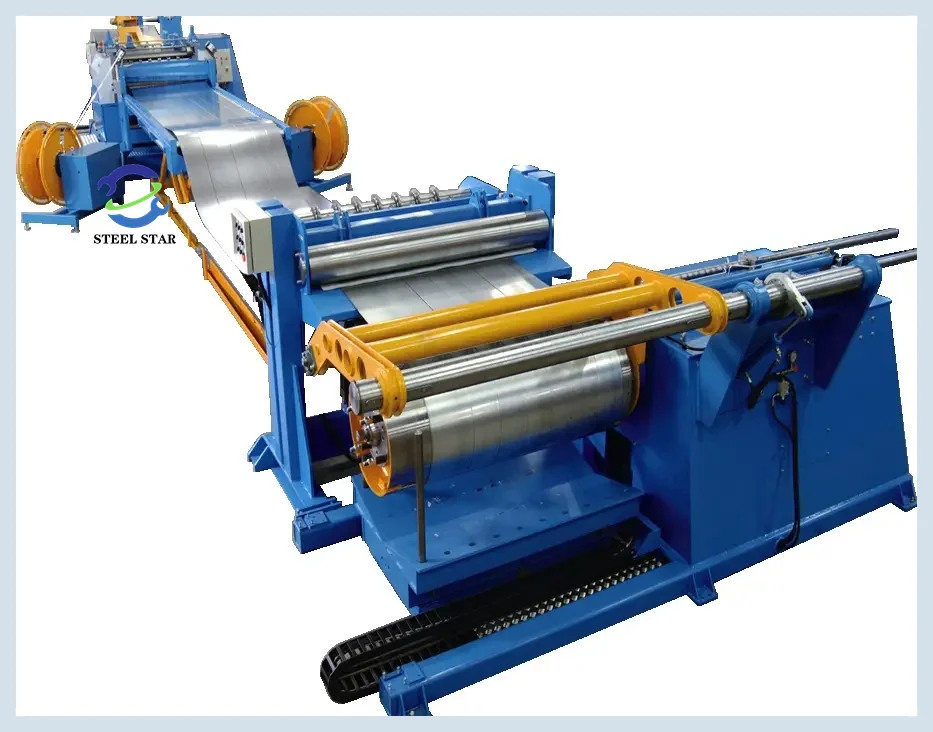

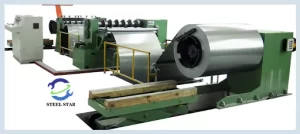

Equipment Production Line:

Slitting machine structure :

The equipment composition of the slitting machine series generally includes: unwinder, guide device, unwinding tension device, head shear, threading table, looper, disc shear, guide roller, machine series transfer roller, inlet clamping device, constant tension winding device, edge crusher, scrap car, coiler, lining paper device, etc. Slitting machine series generally have the following forms.

A. Single-entry looper slitting

This type of slitting sets a looper in front of the shearing machine. There are central drive unwinding, tension unwinding, floating roller controlled unwinding and other forms of sending the strip into the inlet looper. This method can achieve micro-tension or zero tension shearing to avoid slipping of the shear blade; at the same time, the unwinder can be used without a centering device, and the strip can be centered in the looper.

B. Single-exit looper slitting

This type of slitting sets a looper after the shearing machine, and the sheared strip is pushed by the shearing machine into the tension-free looper located between the shearing machine and the tensioning device. For thin strips, an inlet edge guide system may be required to ensure stable unwinding of the strip during shearing. This method can effectively avoid the problem of asynchronous coiling of each strip caused by thickness difference, and realize coiling of the strip by controlling the coiling tension; due to the setting of the outlet looper, the strip can flow out of the shear blade freely, avoiding the wear of the strip on the shear blade under tension and affecting the life of the shear blade; at the same time, due to the absence of tension at the outlet, the phenomenon of strip necking is avoided. Single outlet looper is used more.

C. Double looper slitting

Double looper slitting combines the two forms of entrance looper slitting and exit looper slitting. After leaving the coiler and before entering the shearing machine, the strip is fed into a free looper by the unwinder or a pinch roller device or a tensioning device. After the sheared strip leaves the shearing machine, it is sent to another looper and then enters the tensioning device. Therefore, this slitting method is called “double looper” slitting. With this form of slitting, the slitting machine is only used to split the strip, thus eliminating the possibility of the strip slipping on the scissors. This method neutralizes the characteristics of single entrance looper and single exit looper, and is suitable for shearing thin and soft strips.

Slitting machine, also known as slitting line, slitting machine, slitting machine, is a name for metal slitting equipment.

1. Purpose: Suitable for longitudinal shearing of metal strips and rewinding the slit narrow strips into coils.

2. Advantages: easy operation, high cutting quality, high material utilization, stepless speed regulation of cutting speed, etc.

3. Structure: It consists of unwinding (unwinding), material positioning, slitting longitudinal shearing, coiling (rewinding), etc.

4. Applicable materials: tinplate, silicon steel sheet, aluminum strip, copper, stainless steel plate, galvanized plate, etc. 5. Applicable industries: transformers, motors, home appliances, automobiles, building materials, packaging industry, etc.

The adjustment of the longitudinal shear blade mainly involves two parameters: the gap and overlap of the blade. The selection is based on the alloy material and thickness. Generally, the gap of the blade is 0.04~0.12 times the thickness of the plate and strip, and the overlap can be between 0 and 4.0 mm, which needs to be determined according to different products.

Slitting machine is also called slitting line, slitting machine, slitting machine, which is used to unwind, slitting and rewind metal coils into coils of required width. It is suitable for processing cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel and various metal materials after surface coating.

1. Application: It is suitable for longitudinal shearing of metal strips and rewinding the slit narrow strips into coils.

2. Advantages: easy operation, high cutting quality, high material utilization rate, stepless speed regulation of cutting speed, etc.

3. Structure: It consists of unwinding (unwinding), material positioning, slitting slitting, coiling (rewinding), etc.

4. Applicable materials: tinplate, silicon steel sheet, aluminum strip, copper, stainless steel plate, galvanized plate, etc.

5. Applicable industries: transformers, motors, home appliances, automobiles, building materials, packaging industry, etc.

Technical parameters of slitting machine:

The specifications of slitting machine have many main parameters, the most important parameters and parameter data are as follows

(For example: 3 x1600 slitting line plan)

Main technical parameters

1. Raw material parameters

Material Cold rolled plate, stainless steel plate, aluminum plate, galvanized plate, iron plate, color coated plate

Plate thickness 0.15~ 3.0 mm

Plate width 500~1600mm

Inner diameter of coil Φ508mm/Φ610mm

Outer diameter of coil ≤Φ1600mm

Maximum weight of coil 10000kg

2. Finished product parameters

Strip inner diameter Φ508mm

Strip outer diameter ≤Φ1600mm

Maximum coiling weight 10000kg

Minimum strip width 15mm (plate thickness ≤0.5mm)

Width accuracy ±0.05mm (plate thickness ≤1mm)

±0.1mm (plate thickness >1.1mm)

Shear burr 5% plate thickness, minimum 0.03mm

Strip straightness 0.5mm/1000mm (standard high-quality plate, plate width>100mm)

3. Equipment parameters

Number of longitudinal cutting strips 7 strips (thickness 3mm)

12 strips (thickness 2mm)

25 strips (thickness 1mm)

55 strips (thickness <0.5mm)

Slitting speed max150m/min

Total power about 220KW

Factory Information:

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)

Loading trolley – unwinder – material guiding device – traction leveling machine – end shearing machine – 1# swing bridge – deviation correction feeding device – longitudinal shear – waste edge winder – material feeding rack – 2# swing bridge – pre-dividing device – tensioner – feeding device – dividing shearing machine – steering roller – rear axle – winder – unloading trolley – auxiliary support – hydraulic system – electrical system.