A C Channel Roll Forming Machine and a C Purlin Roll Forming Machine are specialized industrial machines designed for forming metal sheets into a “C” shaped profile commonly used in construction, particularly for building frames and structural support systems. Here’s a breakdown of each:

1. C Channel Roll Forming Machine

- Purpose: This machine shapes metal sheets into a C-channel profile, typically used in structural and construction applications. C channels are known for their high strength-to-weight ratio and are ideal for applications requiring strong and lightweight structural support.

- Features: The machine uses multiple sets of rollers to bend and shape the metal sheet gradually into the “C” profile. It often includes automated control systems for precise dimensions and cutting systems for customized lengths.

- Applications: Primarily used in the construction of steel structures, building frameworks, shelving, and sometimes automotive parts.

2. C Purlin Roll Forming Machine

- Purpose: Similar to the C Channel machine, this machine is designed specifically to produce C purlins, a particular type of C-shaped support that is widely used in roofing and wall structures.

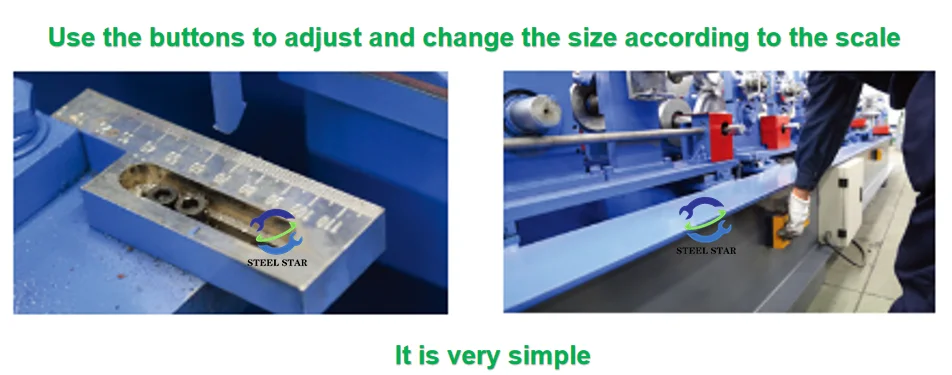

- Features: The machine also uses a roll-forming process, with rollers specifically adjusted to create C purlins that are optimized for load-bearing and fit within roofing systems. Many C Purlin machines come with an adjustable feature, allowing operators to create different sizes of C purlins from one machine.

- Applications: These are commonly used as horizontal structural supports in steel buildings, providing a foundation for roofs and walls in construction projects.

Both machines are crucial for producing high-quality, consistent metal profiles quickly, which are essential in the construction industry for creating durable and efficient building frameworks.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)