A Metal Deck Roll Forming Machine and a Deck Floor Roll Forming Machine are specialized machines used in manufacturing metal decking systems for construction purposes.

Metal Deck Roll Forming Machine:

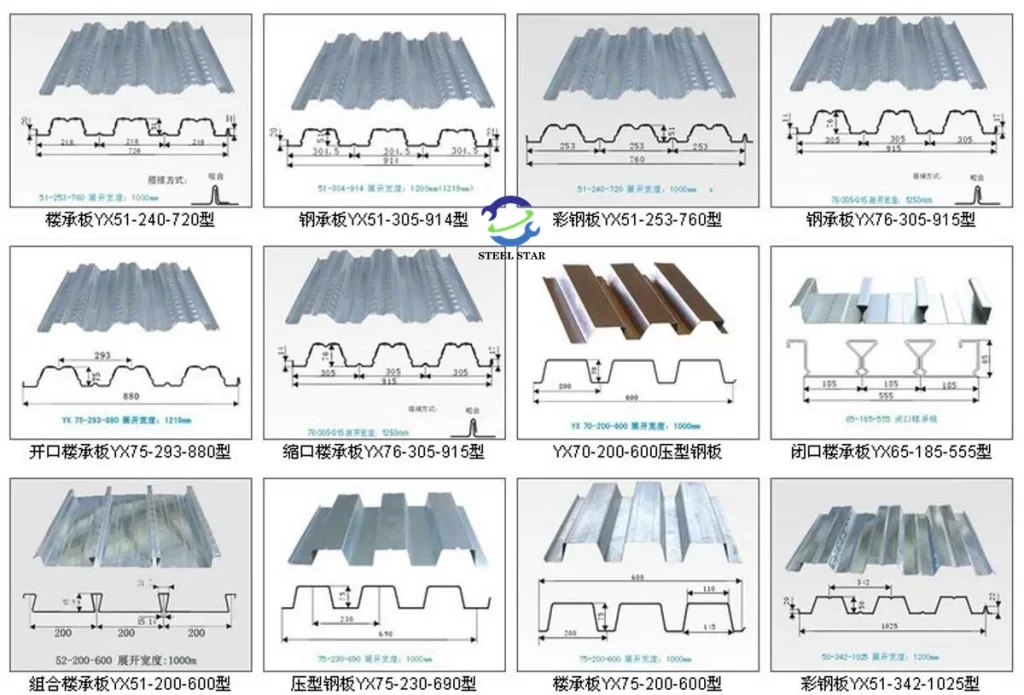

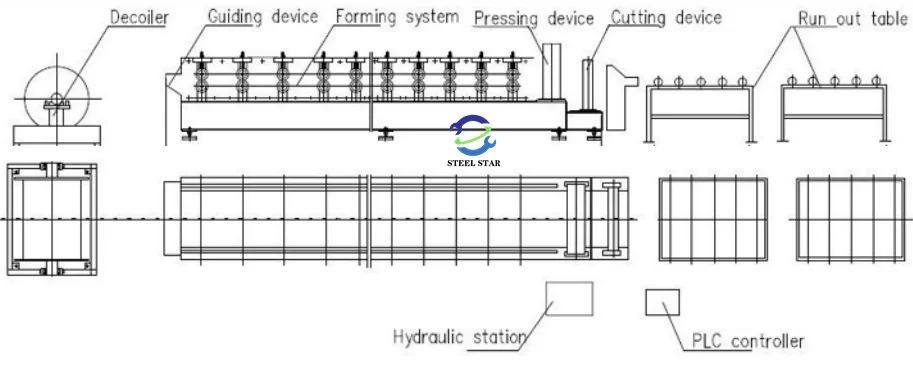

- Function: It creates metal deck panels from coiled steel or other metals by passing the material through a series of rollers that shape it into the desired profile.

- Applications: Primarily used in flooring systems for commercial buildings, warehouses, and industrial structures. They provide support for concrete slabs and are integral in the construction of composite floors.

- Advantages: High production efficiency, limited labor costs, and precision in dimensions and profiles.

Deck Floor Roll Forming Machine:

- Function: Similar to the metal deck roll forming machine, but typically focuses specifically on producing floor decks that can accommodate heavier loads and have integrated features for composite construction.

- Applications: Used for applications requiring strong load-bearing floors, common in shopping malls, airports, and bridges.

- Features: May include capabilities for producing various deck profiles, adjustable speeds, and features for automatic stacking and cutting.

Considerations When Choosing:

- Material Types: Ensure the machine can handle the thickness and type of metal you plan to use.

- Profile Variety: Check if the machine can create the profiles necessary for your specific design requirements.

- Production Capacity: Consider how much product you need to produce and the speed of the machine.

- Space and Setup: Ensure you have adequate space for the machine and its operations.

If you need more specific information or comparisons between models, feel free to ask!

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)