Shutter Door Roll Forming Machine,Shutter Door Forming Machine:

The Shutter Door Roll Forming Machine: An Engineering Marvel In the dynamic realm of modern manufacturing, the shutter door roll forming machine has emerged as a true game-changer, revolutionizing the production of shutter doors across a multitude of industries. This highly sophisticated piece of equipment is the linchpin that ensures the seamless fabrication of top-notch shutter doors, catering to a diverse array of applications.

How It Works:

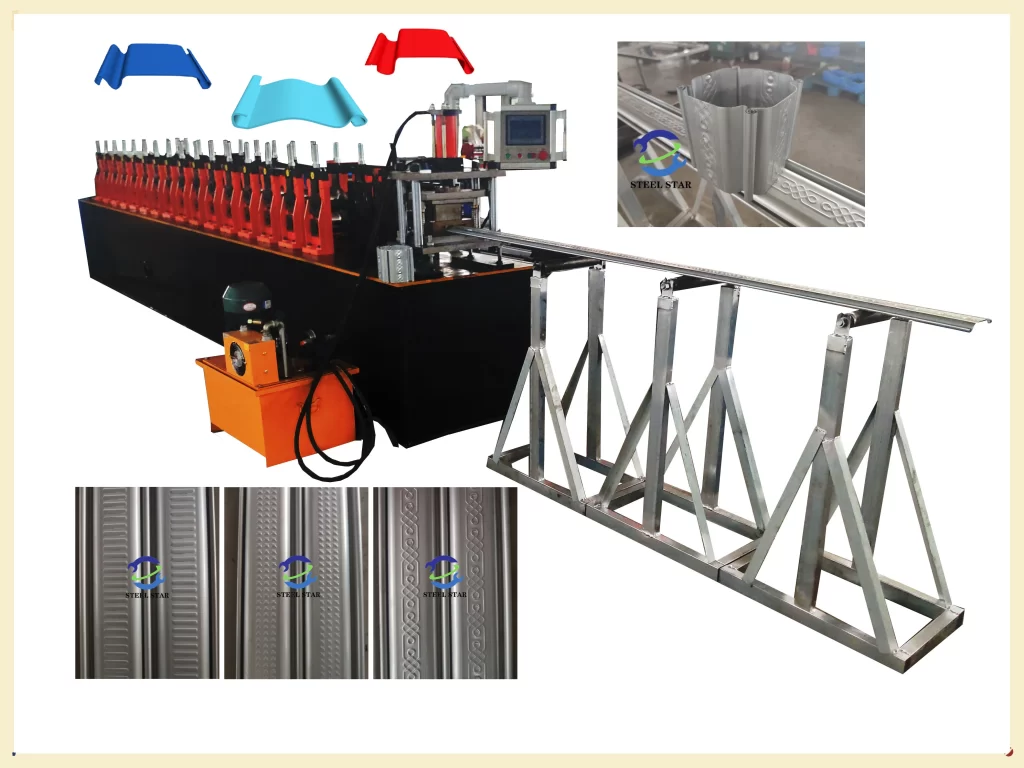

At its fundamental level, the operation of a shutter door roll forming machine hinges on a deceptively simple yet exquisitely intricate principle. The process commences with a hefty coil of raw material, predominantly steel or aluminum, which is meticulously fed into the machine’s maw. As the material embarks on its transformative journey, it snakes through a precisely calibrated sequence of rollers. These rollers, engineered with painstaking precision, incrementally coax the initially flat strip into the meticulously designed profile of a shutter door slat. Each roller exerts a carefully calibrated pressure, artfully applying bends and curves in a step-by-step fashion. By the time the material exits the machine, it has been transmuted into a flawlessly formed slat. This continuous process unfolds with remarkable fluidity, capable of churning out dozens, or even hundreds, of identical slats per minute, contingent on the machine’s specific capacity and customized settings.

Key Components:

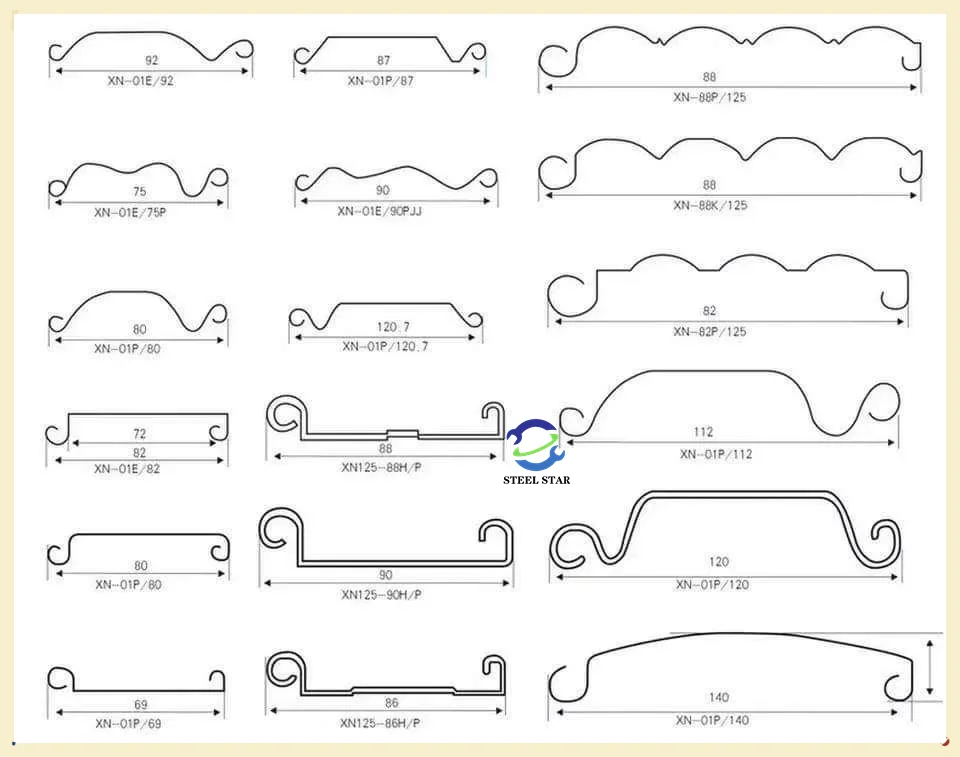

The machine’s anatomy is composed of several indispensable elements that function in harmonious synchrony. The decoiler, a stalwart sentinel, cradles the voluminous coil of raw material and oversees a seamless, unimpeded feed. Equipped with state-of-the-art tension control mechanisms, it ensures that the material enters the forming section with just the right amount of pull. The forming rollers, undeniably the heart and soul of the operation, are crafted from premium hardened steel. Custom-designed for each unique shutter door model, they sport an array of grooves, ridges, and contours that meticulously mold the metal into its intended shape. The cutting device, another critical cog in the machine’s machinery, can be precisely programmed to sever the formed slats to exacting lengths. Leveraging advanced servo-motor technology, it delivers pinpoint accuracy, ensuring each slat is the perfect size. Complementing these is a user-friendly control panel, affording operators the power to tweak parameters such as roller speed, forming pressure, and cutting length, thereby rendering the machine adaptable to a kaleidoscope of production requisites.

Advantages in Manufacturing:

The manifold advantages bestowed by the shutter door roll forming machine are nothing short of remarkable. Chief among them is its prodigious efficiency. When pitted against traditional manufacturing methodologies, which often involve laborious manual cutting and shaping, it slashes production time to a fraction. Consider a bustling factory tasked with fulfilling a large order of shutter doors for a chain of supermarkets. With a roll forming machine humming away, what might have taken weeks of painstaking labor can now be accomplished in a matter of days, if not hours. This newfound speed translates into lightning-fast turnaround times, empowering manufacturers to meet even the most stringent deadlines with aplomb. Cost-effectiveness is another jewel in its crown. By automating the production process, the need for a legion of workers toiling over each door is significantly diminished, leading to substantial savings in labor costs. Moreover, the machine’s precision engineering minimizes material waste. In a real-world scenario, a manufacturer producing shutter doors for a high-end condominium complex can rest assured that every inch of the costly metal coil is optimally utilized, with minimal scrap left behind. This not only curtails expenses but also aligns with sustainable manufacturing practices. The consistency of the output is yet another feather in its cap. Each slat that emerges from the machine is a carbon copy of its predecessors, adhering to the most exacting dimensions and quality benchmarks. This uniformity guarantees a seamless fit and smooth operation when assembling the shutter doors, eliminating the headaches of irregular components that could plague traditional production methods.

Applications Across Industries:

The applications of shutter doors birthed by these remarkable machines span a vast and varied landscape. In the commercial arena, they are an omnipresent fixture. Take, for instance, a bustling downtown shopping mall. Here, the shutter doors fabricated by roll forming machines serve a dual purpose. By night, they transform into impenetrable barriers, safeguarding high-end boutiques filled with designer apparel and luxury accessories from potential theft and vandalism. When morning breaks and the stores open for business, the doors roll up smoothly, allowing for an inviting display and easy customer access. In the industrial domain, consider a sprawling automotive manufacturing plant. The heavy-duty shutter doors churned out by these machines are the unsung heroes, partitioning different work zones, shielding delicate machinery from dust and debris during production, and providing a secure perimeter during off-hours. They stand resilient against the cacophony of welding sparks, chemical fumes, and the ceaseless rumble of heavy machinery, ensuring the integrity of the production environment. Even in the residential sphere, homeowners are reaping the benefits. Picture a charming suburban house with a stylish garage. The shutter door, produced with the finesse of a roll forming machine, not only adds a touch of curb appeal but also offers robust security. It becomes a seamless blend of aesthetics and functionality, protecting the family’s vehicles and cherished belongings from the elements and potential intruders.

Innovations and Future Trends:

As the relentless march of technology persists, shutter door roll forming machines are hurtling towards a future replete with innovation. The vanguard of this evolution lies in the integration of increasingly intelligent control systems. These systems possess an almost sentient ability to self-monitor and dynamically adjust parameters in real-time. In a busy factory floor, if the machine detects a minuscule hiccup in the material feed or an infinitesimal deviation in the forming process, it springs into action, making instantaneous corrections. This not only cements the quality of the end product but also slashes downtime, ensuring a seamless production flow. Parallel to this, manufacturers are embarking on intrepid forays into the realm of novel materials. Composite alloys, with their tantalizing blend of enhanced strength, superior corrosion resistance, and featherlight properties, are being explored. This paves the way for shutter doors that could potentially offer better insulation, a boon for energy-efficient homes and climate-controlled industrial spaces. Imagine a warehouse in a frigid climate zone, where the shutter doors not only keep the cold at bay but also reduce heating costs thanks to their innovative insulation capabilities. Additionally, these new materials could herald a new era of visually stunning shutter doors, with unique finishes and textures that transform them from mere functional entities into design statements, catering to the ever-evolving whims and fancies of the market. In summation, the shutter door roll forming machine is far more than a mechanical behemoth on a factory floor. It is the alchemist’s crucible that transmutes raw metal into the building blocks of security, functionality, and style in edifices spanning the globe. Its ceaseless evolution holds the promise of unfurling a tapestry of even more advanced and versatile shutter door solutions, poised to meet the kaleidoscopic needs of our modern, fast-paced society. Whether it’s shielding a vibrant commercial hub, fortifying an industrial powerhouse, or adorning a cozy residential abode, this machine stands as a paragon of manufacturing innovation.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)