Building a Steel Building: A Comprehensive Guide

In the modern construction landscape, steel buildings have emerged as a popular choice for a diverse range of applications, from industrial warehouses to stylish commercial spaces and even residential dwellings. The process of erecting a steel building is a meticulous blend of precise engineering, skilled labor, and adherence to safety and quality standards.

Planning and Design Phase

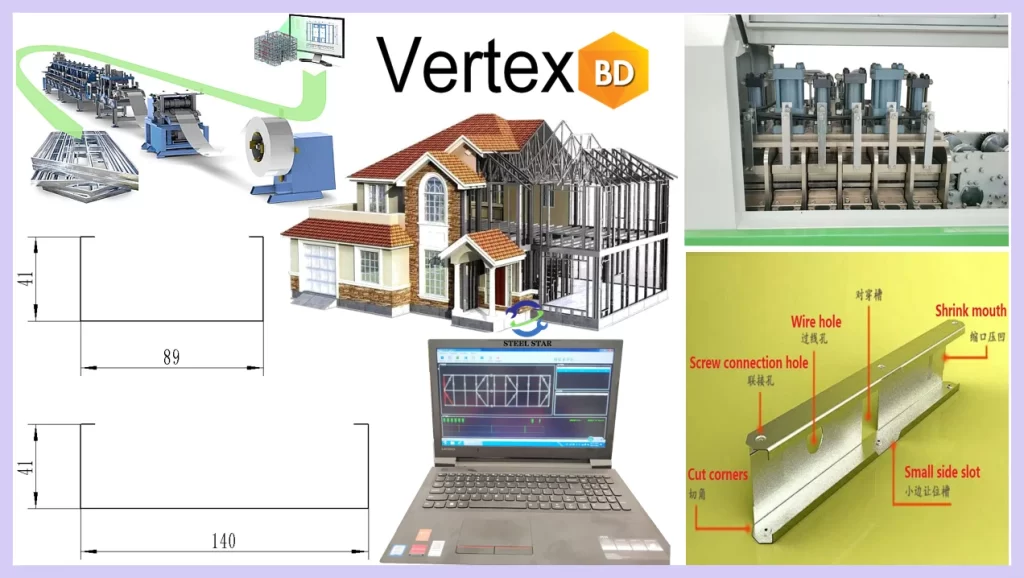

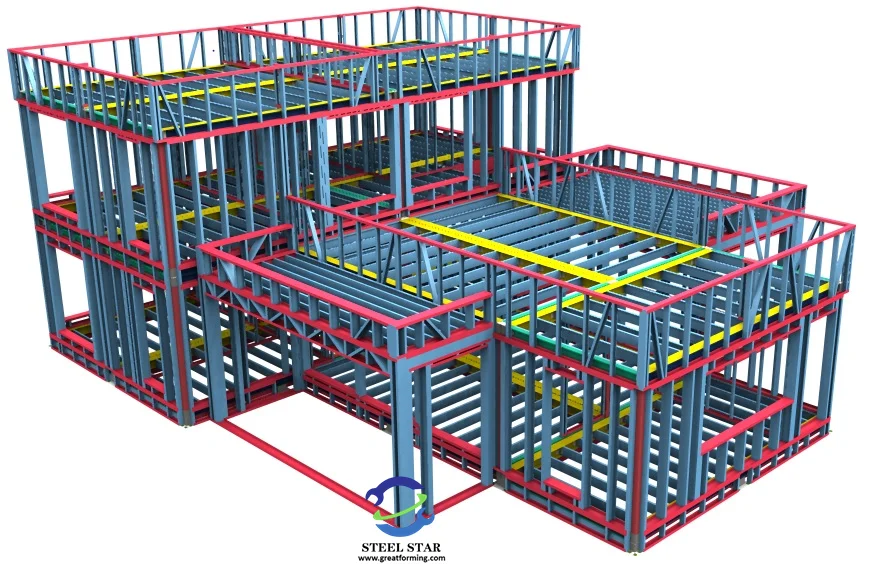

The journey of building a steel building commences with meticulous planning. Architects and engineers collaborate to conceptualize a structure that aligns with the intended use, local building codes, and environmental factors. The design must factor in load-bearing requirements, wind and seismic resistance specific to the building site’s location. Advanced software is employed to create 3D models, allowing for virtual walkthroughs and stress analysis of the steel framework. This phase also involves obtaining the necessary permits, which demands comprehensive documentation of the design, including structural calculations and site plans, submitted to local authorities for approval.

Foundation Preparation

A solid foundation is the bedrock of any successful steel building project. Depending on the soil type and building size, options range from shallow spread footings to deep pile foundations. Excavation crews meticulously dig to the required depth, ensuring proper leveling. Reinforced concrete is then poured into the forms, with embedded anchor bolts precisely positioned to mate with the steel columns. The concrete must cure adequately to reach its designed strength before the steel erection begins, a process that typically takes several days under controlled conditions, monitored closely to guarantee integrity.

Steel Fabrication and Delivery

Simultaneously, the steel components are fabricated off-site in a specialized factory. Using detailed shop drawings derived from the architectural plans, skilled welders and fabricators cut, bend, and weld beams, columns, and trusses with high precision. The steel is treated for corrosion resistance, often with galvanization or a durable paint coating. Once fabricated, the components are labeled, inventoried, and transported to the construction site. Timely delivery is crucial to maintain the project schedule, with logistics teams coordinating to ensure all pieces arrive in sequence and undamaged, ready for assembly.

Erection Process

When the foundation is set and the steel arrives, the erection crew springs into action. Crane operators play a pivotal role, carefully lifting the heavy steel columns into place and lowering them onto the anchor bolts. Workers then secure and plumb the columns, using temporary bracing to maintain stability as the structure takes shape. Beams and trusses follow, with bolted or welded connections made according to strict engineering specifications. Safety harnesses, nets, and guardrails are installed at every stage to protect workers from falls, as the skeletal frame rises steadily skyward, a testament to coordinated teamwork and expertise.

Enclosure and Finishing

With the steel framework complete, the building is enclosed. Wall and roof panels, often made of metal or insulated composite materials, are attached to the frame. This provides weatherproofing and insulation, crucial for energy efficiency and interior comfort. Doors, windows, and skylights are installed, allowing natural light and access. Interior finishes like drywall, flooring, and electrical and plumbing systems are then integrated, transforming the raw steel shell into a functional, habitable space. Regular quality inspections occur throughout this process to catch any defects early and ensure the building meets all performance expectations.

Quality Assurance and Completion

Before the building is handed over, a series of rigorous quality checks are performed. Structural integrity is verified through non-destructive testing methods, ensuring welds and connections are sound. Insulation values are measured, and waterproofing is tested with simulated rain and wind events. Once all tests are passed, and any necessary adjustments are made, the building is deemed complete. Owners receive comprehensive operation manuals and warranties, signifying the culmination of a complex, yet rewarding, construction endeavor that results in a durable, versatile steel building ready to serve its intended purpose for decades to come.

Building a steel building is an intricate dance of technical know-how, careful coordination, and unwavering commitment to quality. From the initial blueprint to the final finishing touches, each step is vital in creating a structure that stands the test of time and meets the evolving needs of its occupants.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)