Ridge Cap and Ridge Cap Machine: An In – Depth Look

I. Introduction to Ridge Cap

A ridge cap is a crucial component in roofing systems. It is designed to cover and protect the ridge – the highest point where two sloping roof surfaces meet. Ridge caps serve multiple important functions.

A. Function of Ridge Cap

- Weather Protection: The primary function of a ridge cap is to prevent water from seeping into the roof structure at the ridge. Rain, snow, and other forms of precipitation can easily find their way into the smallest gaps at the roof’s peak. The ridge cap acts as a barrier, directing water away from this vulnerable area and ensuring that the interior of the building remains dry. For example, in regions with heavy rainfall, a well – installed ridge cap can prevent leaks that might otherwise cause damage to the attic space and the ceiling below.

- Aesthetic Appeal: Ridge caps also contribute to the overall appearance of the roof. They come in a variety of materials and styles, such as metal, asphalt shingle, and clay tile ridge caps. Aesthetically pleasing ridge caps can enhance the curb appeal of a building, giving it a finished and polished look. In historical or architecturally – significant buildings, the choice of ridge cap can even help to maintain the authenticity of the design.

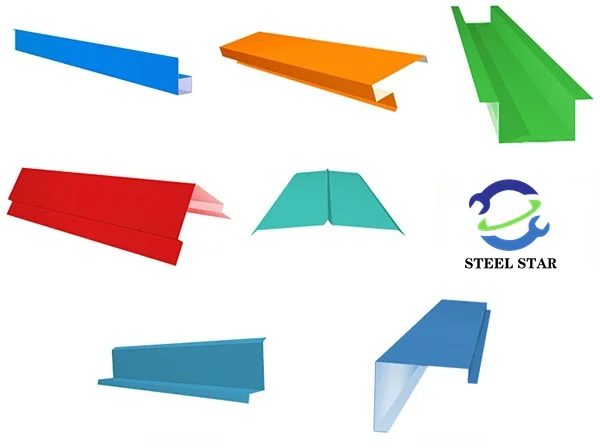

B. Types of Ridge Cap

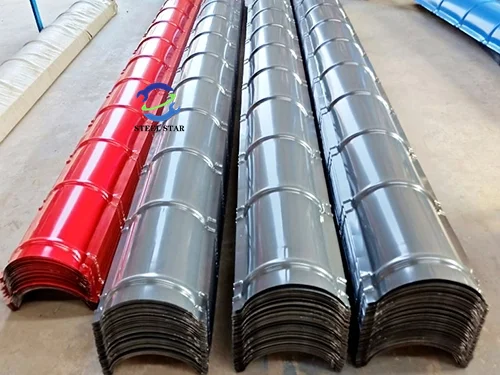

- Metal Ridge Caps: These are highly durable and are often made of materials like aluminum, steel, or copper. Metal ridge caps are popular due to their resistance to harsh weather conditions and long – term durability. For instance, a copper ridge cap can develop a beautiful patina over time, adding to the building’s charm while still providing excellent protection.

- Asphalt Shingle Ridge Caps: They are designed to match the appearance of asphalt shingle roofs. These ridge caps blend in seamlessly with the rest of the shingles and are relatively easy to install. They provide good protection against the elements and are a cost – effective option for many residential roofing projects.

- Tile and Slate Ridge Caps: Commonly used in more traditional or high – end construction, tile and slate ridge caps offer a classic and elegant look. They are heavy and durable, but their installation requires more skill and care due to their weight and fragility.

II. The Role of Ridge Cap Machine

With the increasing demand for efficient and precise roofing installations, ridge cap machines have become an essential tool in the roofing industry.

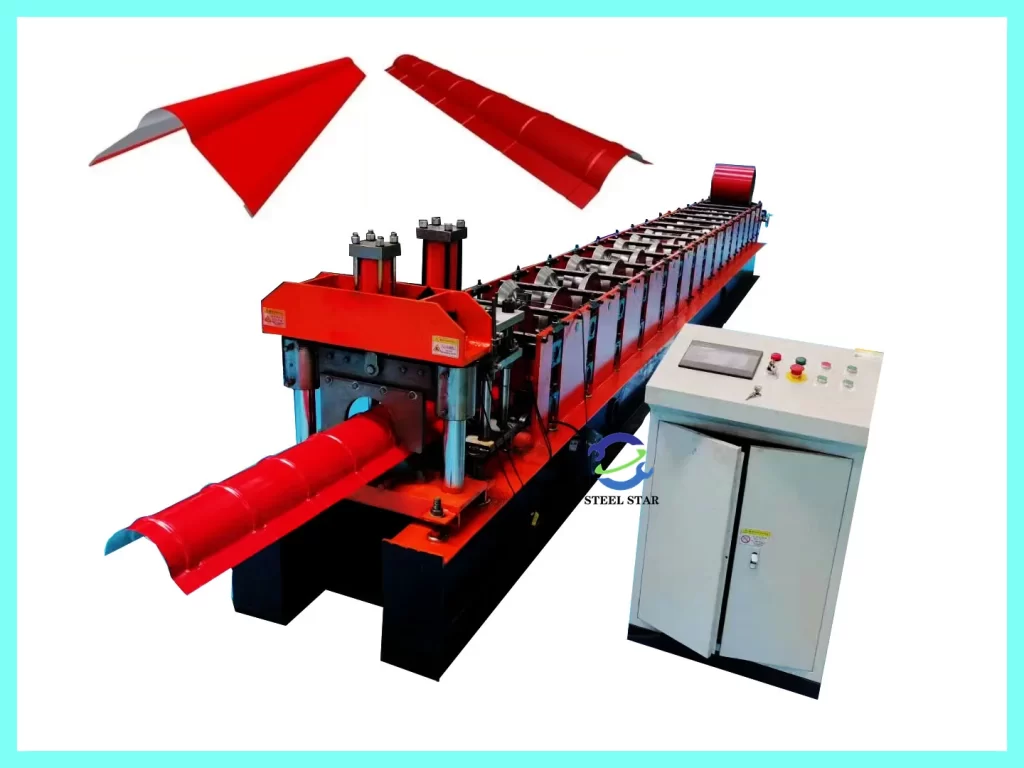

A. What is a Ridge Cap Machine?

A ridge cap machine is a specialized piece of equipment used to fabricate ridge caps. It can take various raw materials, such as metal sheets or asphalt shingle rolls, and shape them into the desired ridge cap configuration. These machines are designed to ensure accuracy and consistency in the production of ridge caps.

B. Types of Ridge Cap Machines

- Metal – Forming Ridge Cap Machines: These machines are used for shaping metal ridge caps. They use a combination of rollers, bending mechanisms, and cutting tools to transform flat metal sheets into the curved or angled shapes required for ridge caps. Some advanced metal – forming machines can even produce custom – shaped metal ridge caps with different profiles and dimensions according to specific architectural requirements.

- Shingle – Processing Ridge Cap Machines: For asphalt shingle ridge caps, these machines are used to cut and shape the shingles into the appropriate ridge cap design. They can handle the cutting of shingle rolls into the correct width and length and can also apply any necessary adhesives or sealants to ensure a proper fit and seal when the ridge cap is installed on the roof.

C. Benefits of Using a Ridge Cap Machine

Versatility: Many ridge cap machines are designed to be versatile, allowing for the production of different types of ridge caps. This means that a roofing contractor can use the same machine to produce metal, shingle, or other types of ridge caps depending on the requirements of the project.

Efficiency: Ridge cap machines can significantly increase the production rate of ridge caps. Manual fabrication of ridge caps can be a time – consuming process, especially when a large number of ridge caps are needed for a roofing project. Machines can produce multiple ridge caps in a short amount of time, reducing labor costs and project completion time.

Precision: The precision offered by ridge cap machines ensures that each ridge cap is of consistent quality. This is crucial for a proper fit on the roof ridge. A precisely fabricated ridge cap will have the correct angles and dimensions, which helps in achieving a seamless and watertight installation.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)