Steel Stud Framing and Steel Stud Framing Machines: Revolutionizing Construction.

Introduction

In the modern construction industry, the use of steel stud framing has emerged as a dominant method for erecting walls and partitions. This innovative approach, along with the advanced steel stud framing machines that support it, has transformed the building process, offering numerous advantages over traditional wood framing.

The Rise of Steel Stud Framing

Steel stud framing involves the use of cold-formed steel members to create the skeletal structure of walls. Unlike wood, which can be affected by moisture, insects, and fire, steel studs provide enhanced durability. They do not warp, rot, or succumb to termite damage, ensuring the long-term integrity of the building envelope. This makes them particularly suitable for regions with high humidity or areas prone to natural disasters where structural resilience is crucial.

Moreover, steel is a recyclable material, aligning with the growing emphasis on sustainable construction practices. Buildings constructed with steel studs can have a reduced environmental footprint compared to those using large amounts of virgin wood.

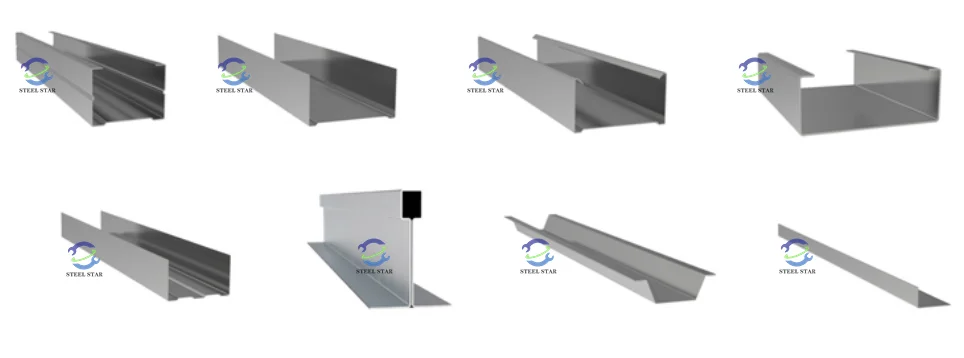

Components of Steel Stud Framing

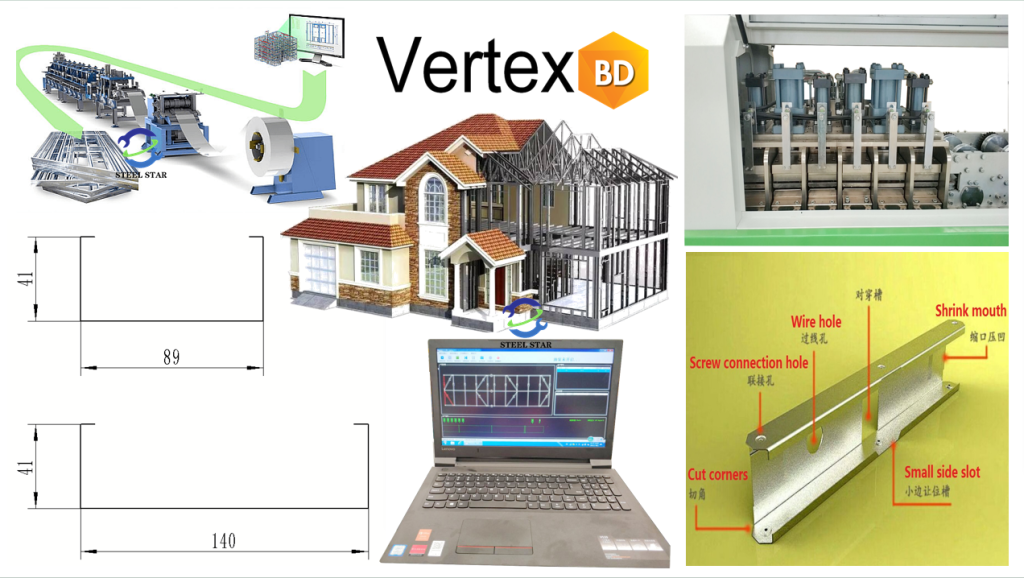

Steel studs typically come in standardized lengths and profiles. They consist of a web, flanges on either side, and punched holes for easy attachment of utilities such as electrical wiring and plumbing. Tracks, which are U-shaped channels, are used to anchor the studs at the top and bottom, providing stability and a framework for installation. Connectors and fasteners, designed specifically for steel, are employed to join different components together, ensuring a rigid and reliable structure.

Advantages in Construction

Precision and Consistency: Steel studs are manufactured to exacting tolerances, allowing for precise alignment during installation. This precision translates into straighter walls, fewer gaps, and better overall fit of finishes like drywall, reducing the need for extensive on-site adjustments and callbacks.

Speed of Erection: With experienced crews and proper planning, steel stud framing can be erected much faster than traditional wood framing. The modular nature of steel components enables a more efficient assembly process, cutting down construction time and labor costs.

Design Flexibility: Architects and designers have greater freedom when using steel studs. They can create complex wall configurations, curves, and high-rise structures more easily due to the strength and adaptability of the material. Taller buildings benefit from the reduced load-bearing requirements compared to heavier wood systems, facilitating the construction of modern, slender façades.

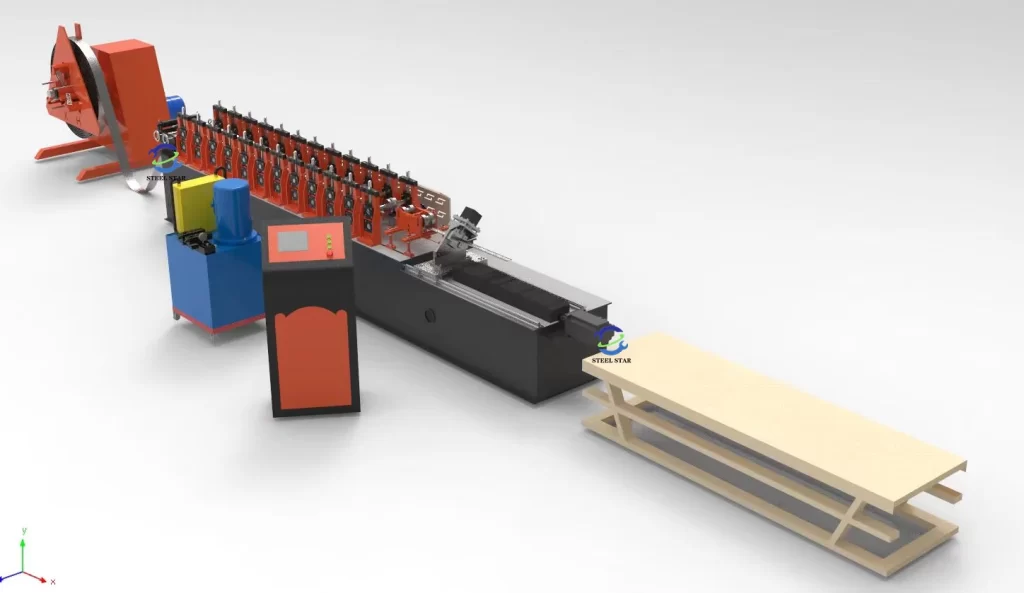

The Role of Steel Stud Framing Machines

1.Roll Forming Machines: These are at the heart of steel stud production. They take coils of flat steel and through a series of rollers, gradually shape them into the desired stud profiles. Advanced roll forming machines can be programmed to produce different stud sizes and configurations with minimal tooling changes, allowing manufacturers to quickly adapt to market demands. The precision of these machines ensures the studs meet strict industry standards for dimensional accuracy.

2.Punching and Notching Machines: To accommodate wiring, piping, and other building services, punching and notching machines are used. They create the necessary holes and cutouts in the studs at precise locations. Automated versions of these machines can be synchronized with roll forming lines, streamlining the production process and eliminating human error in hole placement.

3.Assembly and Welding Machines: In some cases, especially for specialized connectors or prefabricated wall panels, assembly and welding machines come into play. They join different steel components together with strong, reliable welds, creating larger building modules that can be transported and installed on-site, further speeding up construction.

Future Trends

As technology continues to advance, we can expect even more sophisticated steel stud framing machines. Robotics and artificial intelligence may be integrated into production lines to further enhance precision and productivity. Prefabrication of entire wall sections, complete with finishes and built-in services, will likely become more prevalent, allowing for rapid on-site assembly and minimizing construction waste.

In conclusion, steel stud framing and the machines that power its production have revolutionized the construction industry. They offer durability, sustainability, design flexibility, and efficiency, making them a cornerstone of modern building practices. As the demand for high-quality, resilient structures grows, the role of steel stud framing and its associated technologies will only continue to expand.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)