Roll Metal Roofing

Rolled metal roofing is a popular and durable roofing option that has been in use for centuries. It is made by feeding flat metal sheets through a rolling machine to give them a desired shape and thickness. The process typically involves the following steps:

Material Preparation: The metal coil is first cleaned and prepared. Any dirt, rust, or other contaminants must be removed to ensure a smooth, uniform finish.

Roll Forming: The coil is then fed into the rolling machine, which consists of a series of rollers that gradually bend and shape the metal into the desired profile.

Cutting and Coating: After the metal has been shaped, it is typically cut to the desired length and then coated with a protective finish. This finish can be applied through various methods, including painting, galvanizing, or a polymer coating. The finish enhances the metal’s durability and improves its resistance to weather and UV rays.

Rolled metal roofing offers numerous advantages over other roofing materials:

Durability: Metal roofing is incredibly durable and long-lasting, with a typical lifespan of 40-70 years or more. It can withstand harsh weather conditions such as high winds, heavy snow, hail, and fire.

Low Maintenance: Rolled metal roofing requires minimal maintenance, as it is resistant to rust, corrosion, and other types of damage that can affect other roofing materials.

Energy Efficiency: Metal roofing reflects the sun’s rays, helping keep your home cooler in the summer and reducing energy bills.

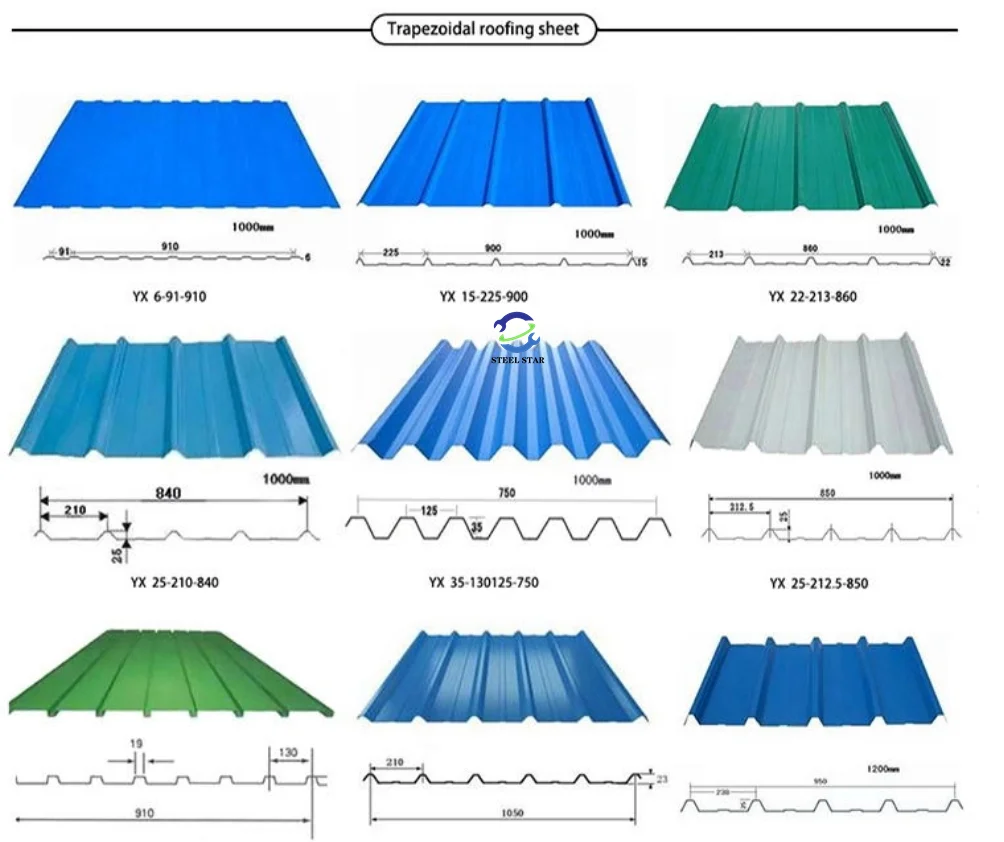

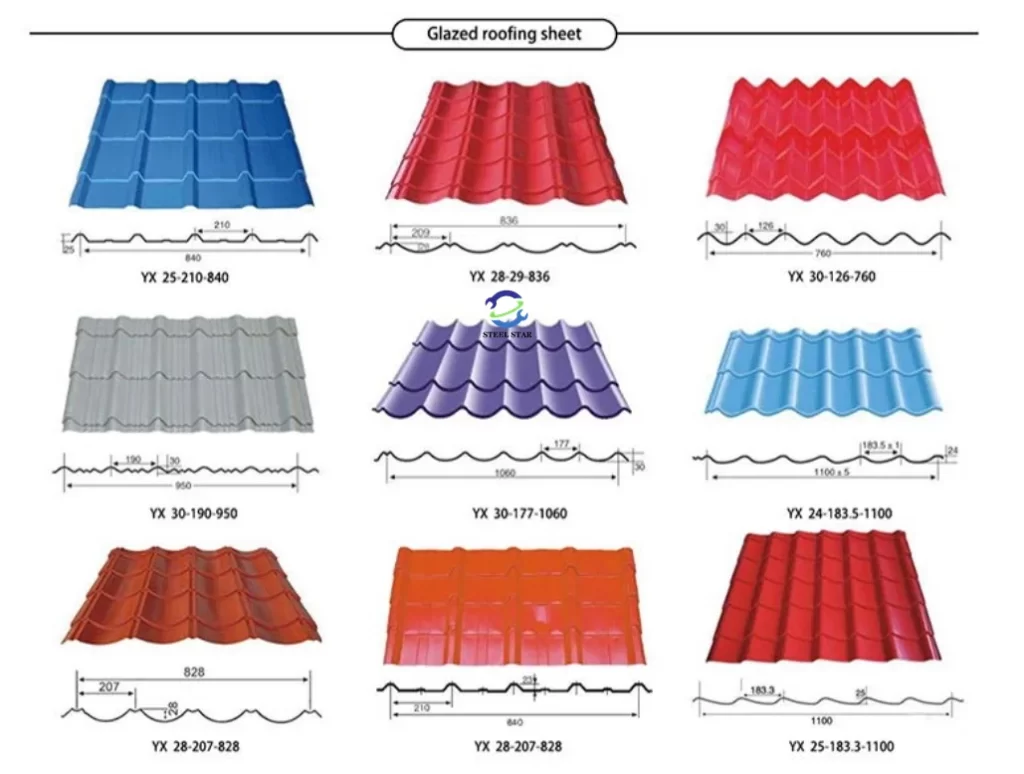

Versatility: Rolled metal roofing comes in a wide range of colors and styles, allowing you to choose a look that complements your home’s architectural style and aesthetic.

Environmentally Friendly: Rolled metal roofing is often made from recycled materials and is 100% recyclable at the end of its life. This makes it a sustainable and eco-friendly choice for homeowners.

Roll Metal Roofing Machine

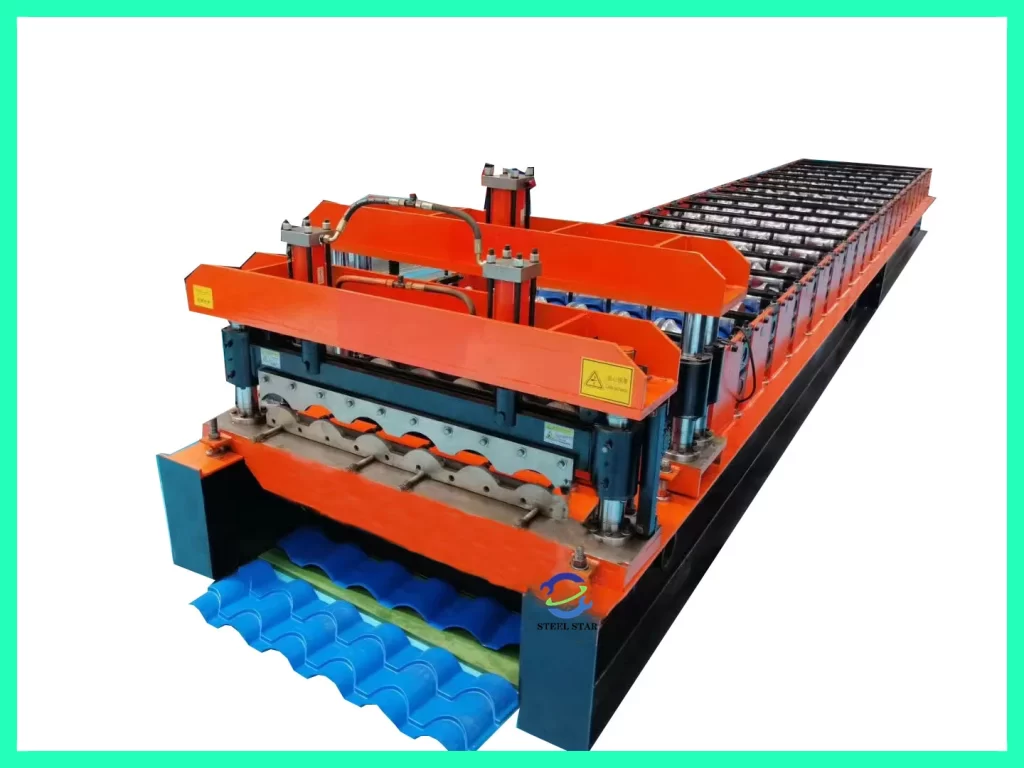

Roll metal roofing machines, also known as roll forming machines for metal roofing, are specialized equipment used to manufacture metal roofing panels. These machines play a crucial role in the production of rolled metal roofing and offer several benefits:

High Efficiency and Consistency: They are capable of efficiently and consistently producing metal roofing panels in large quantities, ensuring uniformity and quality across all the manufactured pieces.

Customization: The machines can be adjusted to produce roofing panels of different sizes, profiles, and shapes to match specific architectural requirements.

Precision and Control: Roll metal roofing machines provide precise control over the shaping and forming process, ensuring that the panels meet the required standards and specifications for weather resistance, durability, and other performance factors.

Cost-Effectiveness: By automating the production process, these machines can significantly reduce labor costs and increase overall productivity, making the manufacturing of rolled metal roofing more cost-effective.

There are various types of roll metal roofing machines available, each designed for specific applications and production requirements:

Portable & Movable Standing Seam Forming Machine: This type of machine is designed to produce standing seam metal panels used for roofing. It is portable and movable, allowing for on-site fabrication, which eliminates shipping damage, short shipments, and many sizing errors.

Roof/Wall Sheet Roll Forming Machine: It is used for making roofing and wall panel sheets by the rolling forming principle

in batch fully automatically. The profile could be like for roofing panel, wall panel and others.

IBR Roof Sheet Making Machine: It is used to produce IBR roof sheets, which are commonly used in roofing applications. The machine can form the metal sheets into the specific profile required for IBR roofing.

Galvanized Corrugated Roof Sheet Forming Machine: This machine is designed to produce galvanized corrugated roof sheets. The galvanized coating provides corrosion resistance, and the corrugated shape gives the sheets added strength and rigidity.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)