Roof Sheet Roll Forming Machine: Technology, Applications, and the Rise of Chinese Manufacturers

In the global construction and manufacturing industries, the roof sheet roll forming machine stands as a cornerstone of efficient, high-quality metal roofing production. This specialized equipment transforms flat metal coils into precisely profiled roofing sheets, catering to diverse architectural needs from industrial warehouses to residential villas. Over the past two decades, China has emerged as a dominant force in the global market for these machines, blending advanced technology, cost-effectiveness, and customizable solutions. This article explores the core technology of roof sheet roll forming machines, their key applications, and the factors that have positioned Chinese manufacturers at the forefront of this industry.

- Understanding Roof Sheet Roll Forming Machines: Core Concepts and Classifications

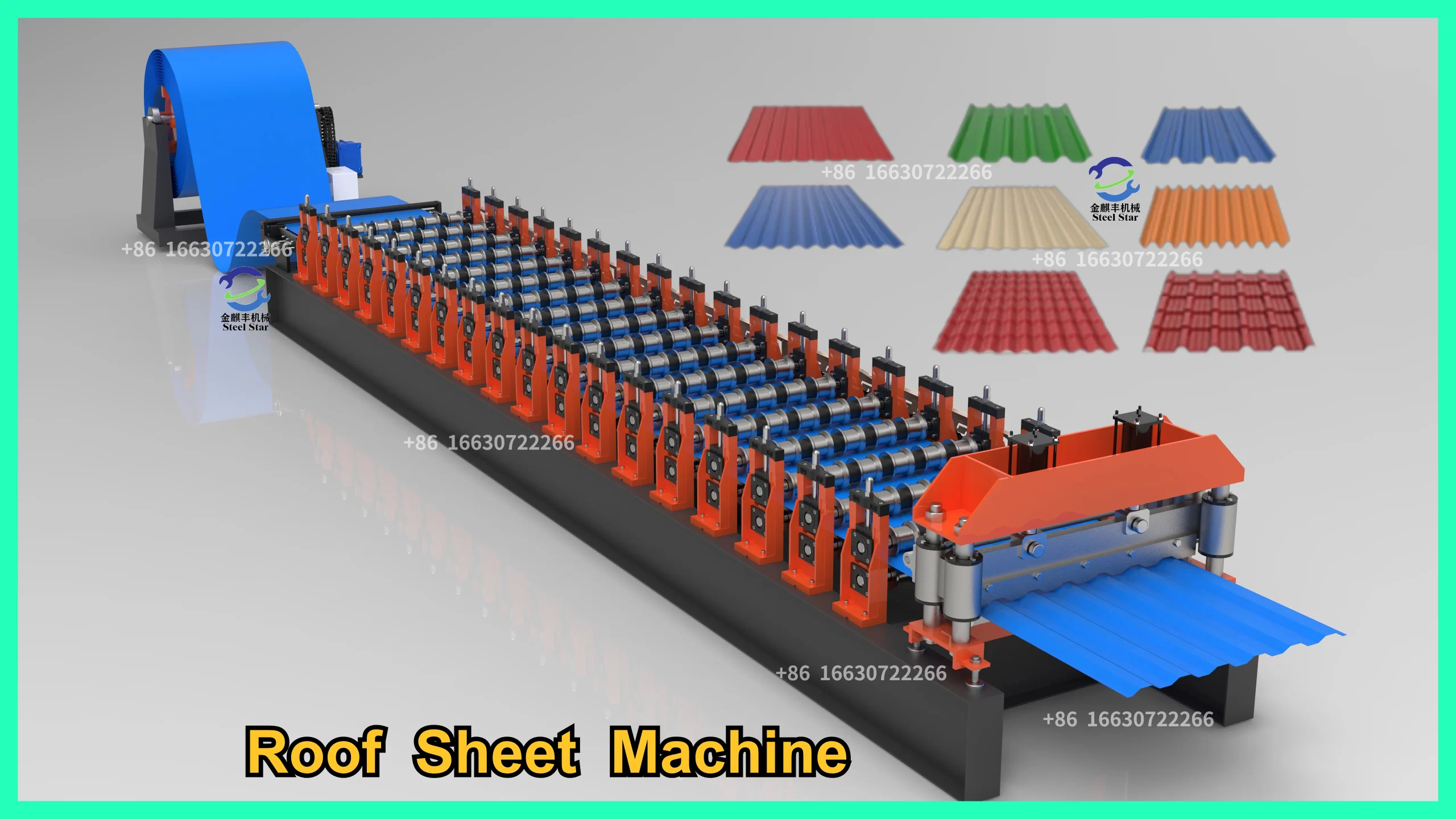

A roof sheet roll forming machine is a continuous processing device designed to shape metal coils into specific roofing profiles through sequential bending operations. Unlike traditional stamping or bending methods, roll forming achieves consistent profiles with minimal material waste, making it ideal for large-scale production. The machines’ versatility lies in their ability to handle various metals, including galvanized steel, stainless steel, aluminum, and pre-painted coils, while adapting to different thicknesses (typically 0.3–1.2mm) and widths (up to 1250mm or customized) .

1.1 Key Classifications by Profile Type

Roof sheet roll forming machines are primarily categorized based on the roofing profiles they produce, each tailored to specific structural and aesthetic requirements:

- Corrugated Roof Sheet Roll Forming Machine: Produces wavy or sinusoidal sheets, renowned for their lightweight and cost-effectiveness. Widely used in agricultural barns, industrial workshops, and temporary structures due to their excellent water drainage and wind resistance .

- Trapezoidal Roof Sheet Roll Forming Machine: Creates box-like panels with deep, uniform ridges. This profile offers enhanced structural strength, making it a preferred choice for commercial buildings, logistics warehouses, and light steel villas. Forming speeds typically range from 8–25m/min, with precision cutting ensuring length accuracy within ±0.5mm .

- Standing Seam Roof Sheet Roll Forming Machine: Manufactures interlocking panels that eliminate exposed screws, providing superior waterproofing. Ideal for modern architectural projects, high-end residential buildings, and areas with extreme weather conditions. The seamless design also enhances aesthetic appeal and longevity .

- Glazed Tile Roof Sheet Roll Forming Machine: Mimics the appearance of traditional clay tiles using metal coils, combining the durability of metal with the classic look of tile roofing. Popular in residential construction and heritage restoration projects .

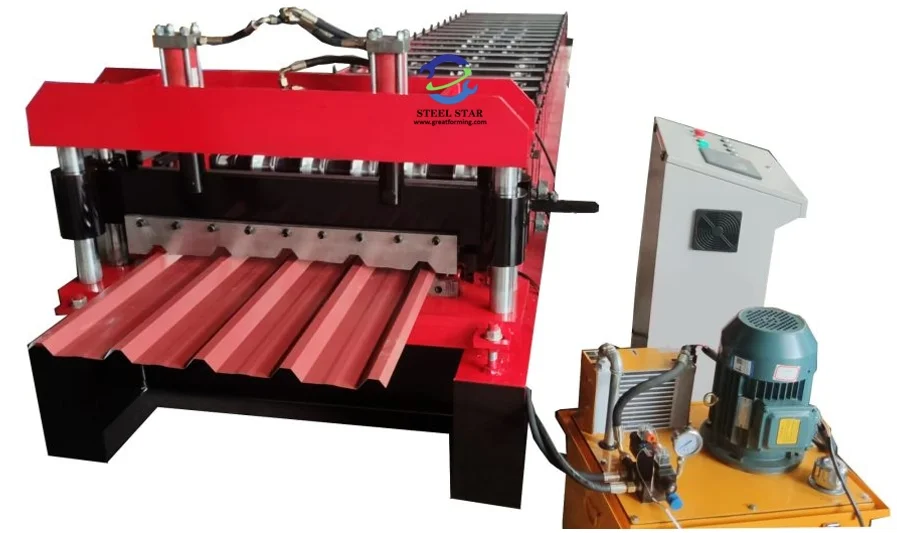

1.2 Core Components and Working Principles

A standard roof sheet roll forming line comprises five essential components, working in synergy to ensure efficient production:

- Decoiler: Feeds flat metal coils into the line, with options for manual or hydraulic operation to adjust tension and alignment. Proper decoiling prevents material deformation and ensures consistent feeding .

- Leveling and Feeding Unit: Straightens the metal strip and guides it into the forming stations. This unit eliminates coil memory (residual curvature from storage) and maintains precise material positioning .

- Roll Forming Stations: The heart of the machine, consisting of 10–15 consecutive roller sets (depending on the profile). Each set gradually bends the metal strip until the desired profile is achieved. Rollers are typically made of hardened tool steel (GCR15 or 45# steel) with chrome coating for wear resistance .

- Cutting and Punching System: Trims the formed sheet to the required length using hydraulic or servo-driven cutters. High-grade CR12MOV steel blades ensure clean cuts without burrs. Optional punching modules can create holes for fasteners or ventilation .

- Stacking and Collection Unit: Automatically stacks finished sheets for packaging and transportation, reducing manual labor and minimizing surface scratches .

The entire process is controlled by a PLC (Programmable Logic Controller) system—often from Siemens or similar brands—with a touchscreen interface. Operators can set parameters such as length, quantity, and speed, enabling fully automated production with just 1–2 workers .

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)