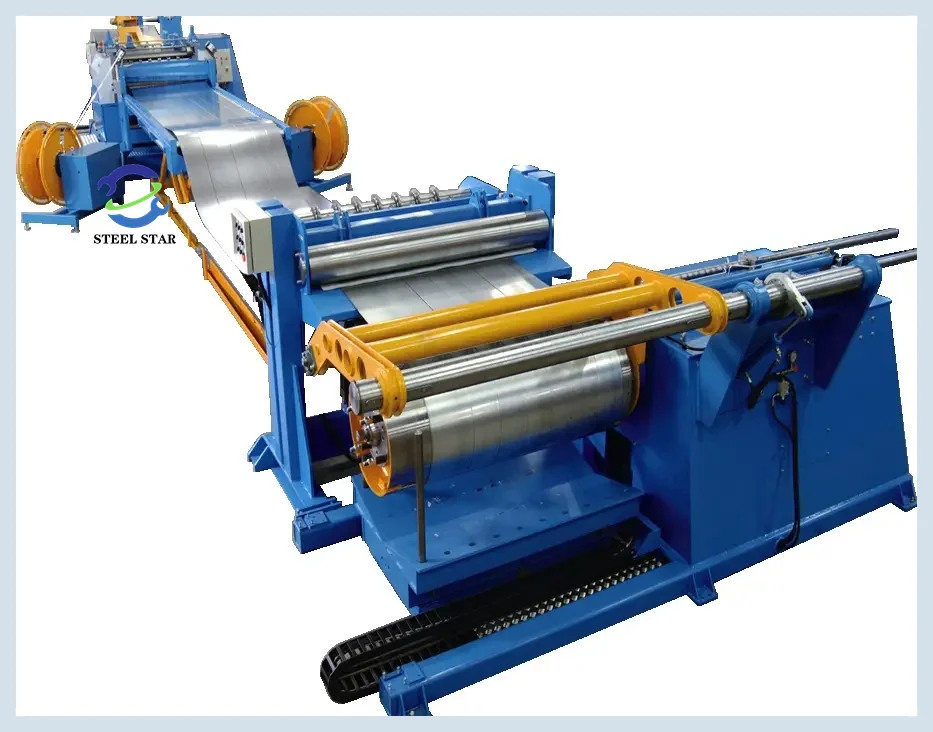

What is a Coil Slitting Line?

A coil slitting line is a continuous processing system designed to longitudinally cut (or slit) a large, wide coil of metal—such as steel, stainless steel, aluminum, or copper—into a series of narrower coils of predetermined widths. This process, known as slitting, maximizes material yield, reduces waste, and provides finished strips ready for subsequent forming processes like stamping, roll forming, or tube making.

Key Components and Their Functions

A modern coil slitting line is an integrated system of several synchronized stations:

Uncoiler (Pay-off Reel): The line starts here, where the master coil is loaded and securely mounted. A tensioning system controls the unwinding of the metal strip into the line, ensuring stability.

Entry Pinch Roll & Straightener: This set of rollers guides the strip and often incorporates a leveler to remove any coil set or crossbow, ensuring flat material enters the cutting section.

The Slitter Head: The heart of the machine. It houses the tooling—upper and lower circular slitting knives mounted on arbors. The precise spacing of these knives determines the width of the output strips. Designs include loop, pull-through, and razor blade styles for different materials and thicknesses.

Strip Separation System: After slitting, the narrow strips tend to curl and intertwine. Systems like wire loops, stripper plates, or rotating separator discs keep the individual strips properly spaced and prevent scratching.

Tension Stand / Drag Unit: Maintains controlled tension on the strips between the slitter and the recoiler, crucial for achieving tight, stable rewound coils.

Recoiler (or Re-winder): The final station where the slit strips are rewound onto individual mandrels. Advanced lines feature dual or turret heads for continuous operation, allowing finished coils to be unloaded while a new set is started.

Scrap Winders: Automatically collect the thin edge trim generated during the slitting process for recycling.

Pneumatic, Hydraulic & CNC Control System: The brain of the operation. Modern lines are governed by Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) for precise control of speed, tension, knife positioning, and line synchronization.

The Slitting Process: A Step-by-Step Flow

Loading & Threading: The master coil is placed on the uncoiler. The leading edge of the strip is manually or automatically fed through the entry guides, straightener, and into the slitter head.

Cutting: As the continuous strip passes through the rotating knives on the slitter head, it is cleanly sheared into multiple, parallel strands.

Separation & Guidance: The slit strips are physically separated and guided into their individual paths toward the recoiler mandrels.

Rewinding under Tension: Each strip is independently wound onto its mandrel at the recoiler. Precise tension control is vital to produce a tightly wound, defect-free coil with a neat, cylindrical shape.

Unloading: Once the master coil is fully processed, the finished narrow coils are banded, removed from the mandrels, and prepared for shipment or the next production step.

Types of Slitting Lines

Loop-Type Slitting Line: Features a looping pit between the slitter and recoiler. The loop absorbs speed differences, making it versatile and suitable for a wide range of materials and thicknesses.

Pull-Through Slitting Line: A more compact design where the recoiler directly pulls the strip through the slitter head. Ideal for thicker, high-strength materials.

Razor Slitting Line: Uses a single rotating knife against a fixed hardened base for extremely thin, soft materials like foil.

Applications and Industries

The output of coil slitting lines is ubiquitous:

Automotive: Strips for seat frames, brackets, and body reinforcements.

Construction: Studs, tracks, and roofing/siding profiles.

Appliances: Components for refrigerators, washing machines, and ovens.

HVAC & Ductwork: Formed parts for heating and ventilation systems.

Precision Engineering: Electrical contacts, shims, and connectors.

Advantages of Modern Coil Slitting

High Efficiency: Processes entire master coils continuously at high speeds.

Superior Precision: Achieves tight width tolerances and clean, burr-minimized edges.

Material Optimization: Minimizes edge trim waste, reducing material costs.

Improved Quality: Produces flat, tightly wound coils ideal for automated downstream production.

Flexibility: Quick tooling changeovers allow for processing different widths and materials.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)