Roof Panel Machine: The Backbone of Modern Roofing Production

Roof panel machines, primarily roll forming equipment, are indispensable in the construction industry, transforming metal coils into precision-engineered roofing panels efficiently and reliably. These specialized machines have revolutionized how roof components are manufactured, offering speed, consistency, and versatility that traditional methods cannot match.

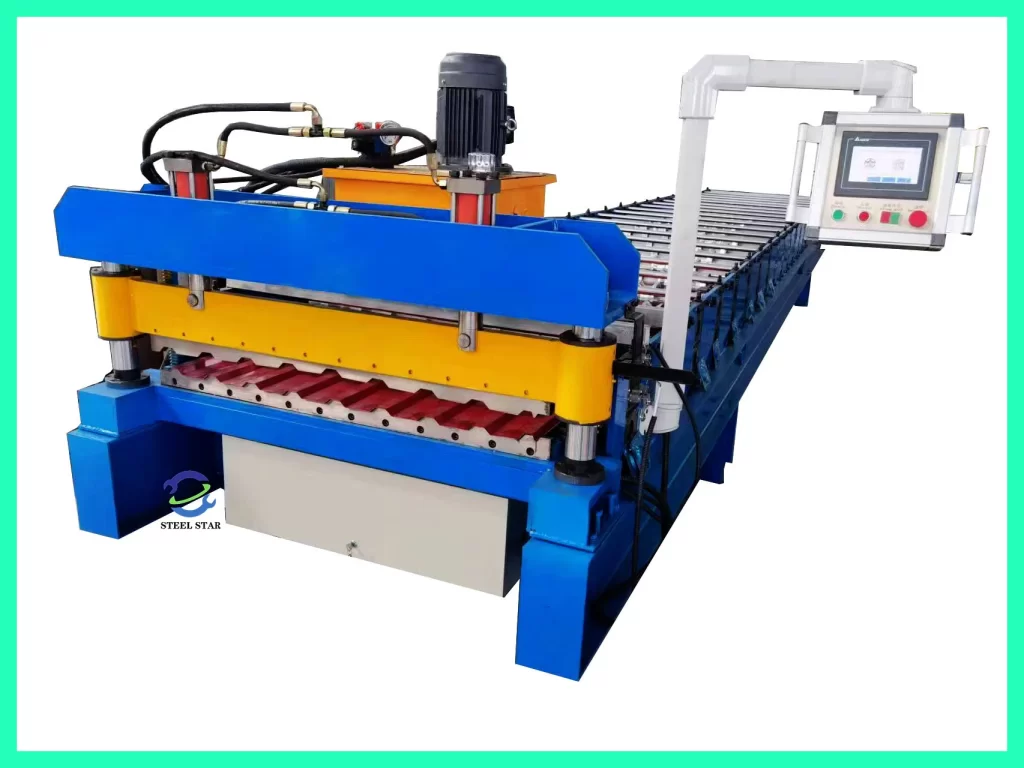

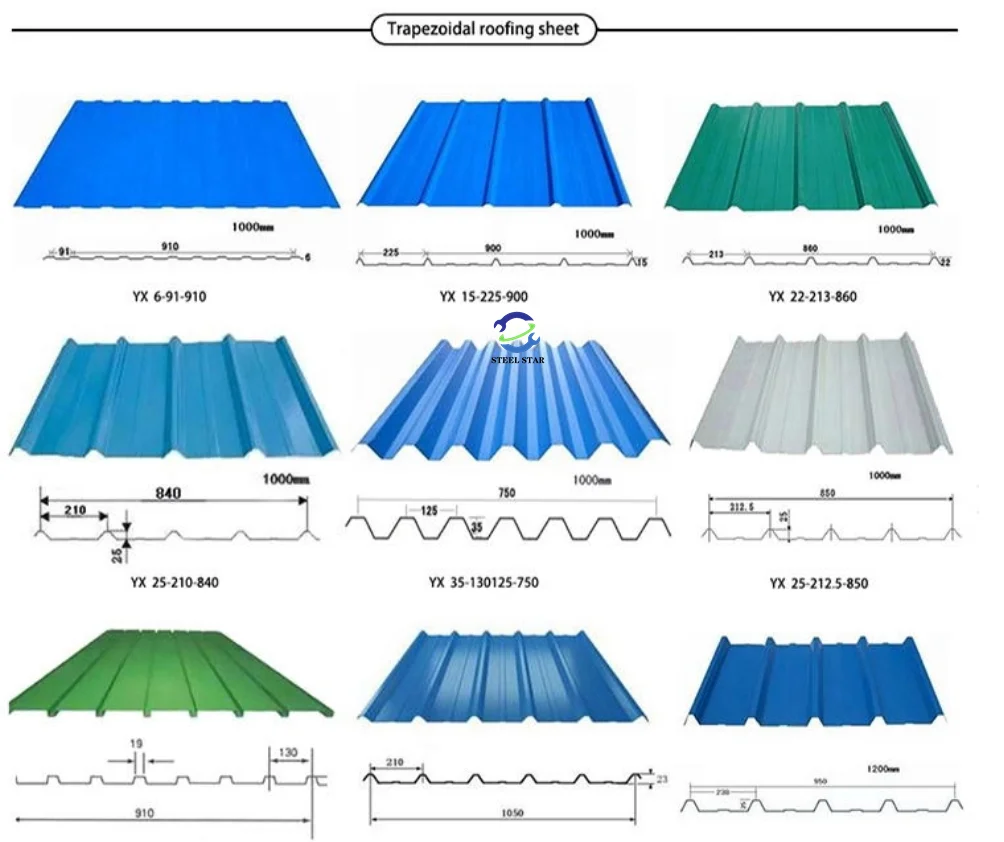

At their core, roof panel machines operate on the cold roll forming principle. The process begins with loading a metal coil—typically galvanized steel, aluminum, or colored steel—onto a decoiler, which feeds the material steadily into the machine . The metal strip then passes through a series of precisely calibrated roller stations, each gradually bending the material into the desired profile—whether corrugated, trapezoidal, or curved . This incremental shaping preserves the metal’s structural integrity while ensuring uniform dimensions. After forming, a shearing unit cuts the panel to a predetermined length, and automated stackers collect the finished products . Modern models integrate PLC control systems (from brands like Mitsubishi or Siemens) for precise parameter adjustment, minimizing human error .

Roof panel machines come in diverse types to suit different production needs. Manual roll formers are compact, ideal for small-scale projects or on-site fabrication, while automatic models handle high-volume production with speeds up to 60 meters per minute . Specialized variants include corrugated roof panel machines, curved roof panel machines, and double-layer decking forming machines, each tailored to specific profiles and applications . Cassette-type machines offer quick profile changes, enabling manufacturers to switch between designs efficiently .

The advantages of these machines are multifaceted. They boost production efficiency significantly, reducing lead times compared to manual fabrication . Their precision ensures consistent panel quality, with finished products boasting excellent durability, weather resistance, and structural strength . Environmental benefits include minimal material waste and compatibility with recyclable metals, aligning with green building standards like LEED . Customization is another key strength—machines can be adjusted to produce panels of varying thicknesses (0.3–0.8mm), widths, and profiles, meeting unique architectural requirements .

Applications of roof panel machines span residential, commercial, and industrial sectors. The panels they produce are used in factories, warehouses, shopping malls, villas, and modular buildings . They excel in creating roofing for large-span structures and are increasingly adopted in BIPV (Building-Integrated Photovoltaics) projects, thanks to their compatibility with solar integration . Emerging economies in Asia, Africa, and South America are driving demand, as rapid urbanization fuels the need for cost-effective, durable roofing solutions .

The industry is evolving rapidly, with key trends shaping machine development. Automation and digitization are paramount—modern machines feature remote monitoring, predictive maintenance, and integration with MES systems . Energy efficiency is a priority, with low-consumption designs and waste-recycling systems becoming standard . The rise of modular construction and green building certifications has spurred demand for machines that produce lightweight, eco-friendly panels . Additionally, global market expansion, particularly via “Belt and Road” initiatives, has made Chinese-manufactured machines popular worldwide, thanks to their CE certification and competitive pricing .

When selecting a roof panel machine, factors like production capacity, material compatibility, speed, and customization options are critical . For large-scale operations, automatic machines with high decoiler capacity (5–15 tons) and fast production speeds are ideal, while manual models suit small projects . Ensuring the machine meets regional power requirements (220V/380V/415V) and comes with reliable after-sales support is also essential .

In summary, roof panel machines are the cornerstone of modern roofing production, blending efficiency, precision, and sustainability. As the construction industry embraces industrialization and green building, these machines will continue to evolve, driving innovation in roofing technology and meeting the growing demand for high-quality, cost-effective roof panels worldwide.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)