In the realm of modern construction and manufacturing, cold formed steel (CFS) has emerged as a material of choice for its strength, versatility, and sustainability. The transformative technology behind this revolution is the Cold Formed Steel Machine—a sophisticated system of roll-forming equipment that shapes steel at room temperature into precise structural components. This machine is the engine driving the production of everything from wall studs and roof trusses to complex automotive and storage racking parts.

Core Principle: Roll-Forming at Room Temperature

Unlike hot-rolled steel, which is shaped at extremely high temperatures, cold formed steel is manufactured by passing thin-gauge steel coils (typically 0.5 mm to 3 mm thick) through a series of roller dies at ambient temperature. This cold-working process increases the yield strength of the steel through strain hardening along the bends, resulting in a lightweight yet exceptionally strong final product. The machine automates this process with high precision and speed.

Anatomy of a Cold Formed Steel Machine

A complete CFS production line is a symphony of coordinated stations:

- Decoiler & Straightener: The line begins with paying off the raw material—a large coil of galvanized or coated steel sheet. A straightening unit ensures the metal is perfectly flat before entering the forming process.

- Pre-Punching/Notching Station (Critical for CFS): This is a defining feature for structural CFS machines. Before roll-forming, a CNC-controlled punching unit perforates the flat strip with holes for electrical conduits, plumbing, bolt connections, or to create nesting details for easy assembly. This step is vastly more efficient than post-forming punching.

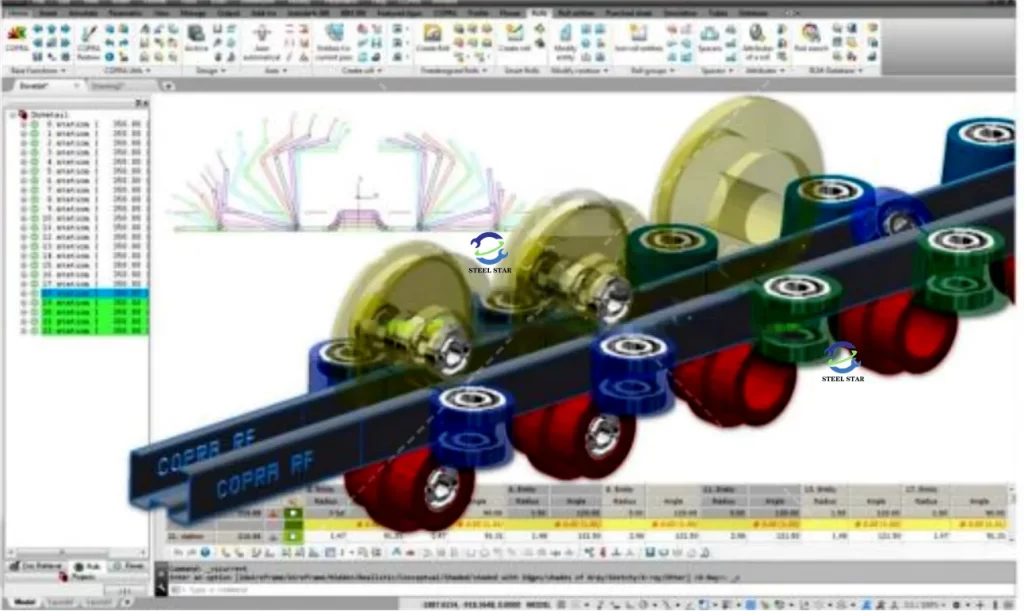

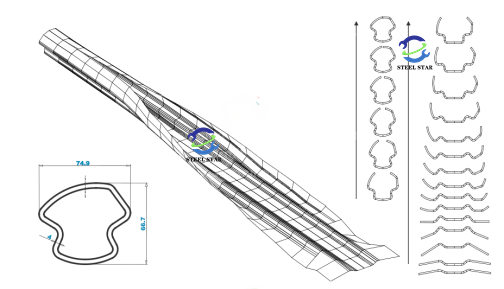

- The Roll-Forming Mill: The heart of the machine. A series of tandemly arranged roll stands, each with a set of contoured hardened steel or carbide rollers, progressively bend the flat strip into the desired cross-section (profile). Complex shapes like C-sections, U-channels, Z-sections, and custom profiles are formed incrementally over 10 to 30+ stands to avoid material stress and ensure dimensional accuracy.

- Cut-Off System: Once formed, the continuous profile is cut to precise lengths. Modern lines use a flying cut system—a hydraulic shear or saw that moves synchronously with the moving steel, making a clean, burr-free cut without stopping production. Length is controlled by a precision encoder.

- Run-Out Table & Stacker: The finished components are conveyed automatically and stacked neatly for bundling and shipment. Advanced lines may include automatic stacking and strapping systems.

Types and Applications

CFS machines are highly specialized based on their end-product:

- Stud & Track Machines: The most common type, producing load-bearing wall studs and runner tracks (channels) for residential and commercial drywall framing.

- Truss & Joist Machines: Manufacture floor joists and roof trusses, often with pre-punched web holes for services.

- Purlin & Girt Machines: Create structural Z and C sections for metal building systems.

- Custom Profile Machines: Designed for high flexibility, producing a wide range of profiles for industries like storage, automotive, and furniture.

Key Advantages and Impact

- Speed and Volume: Enables mass production of framing components at rates exceeding 100 meters per minute.

- Precision and Consistency: CNC-controlled processes guarantee every component is identical, critical for prefabrication and modular construction.

- Material Efficiency: Minimizes waste through precise control and the use of coil stock. Lightweight CFS reduces transportation energy.

- Design Flexibility: Allows for cost-effective customization of profiles to meet specific engineering requirements.

- Sustainability: CFS is 100% recyclable. Its lightweight nature reduces the carbon footprint of structures, and precise manufacturing minimizes on-site waste.

The cold formed steel machine is far more than a simple former; it is a pillar of advanced, industrialized construction. By combining precision engineering, automation, and material science, it transforms a basic steel coil into the essential skeletal framework for modern buildings and products. Its output supports faster, greener, and more resilient construction methodologies, solidifying its role as an indispensable technology shaping the built environment. Wherever efficient, strong, and lightweight steel structures are required, the cold formed steel machine has undoubtedly played a fundamental part in their creation.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)