The Decoil Machine: The Essential First Act in Modern Metal Forming

In the world of coil-fed manufacturing, from automotive production to building materials, every process begins with a single, critical action: efficiently and precisely unwinding the raw material. This fundamental task falls to an often-overlooked yet indispensable piece of equipment—the Decoil Machine (also known as an Uncoiler or Decoiler). Acting as the reliable starting point for countless production lines, the decoil machine ensures a smooth, controlled flow of material, setting the stage for all subsequent operations.

Core Function and Principle

At its essence, a decoil machine is a motorized or passive stand designed to hold, support, and feed a metal coil (a tightly wound roll of sheet metal or strip) into a processing line. Its primary objectives are:

- To support heavy coils safely and securely.

- To unwind the material in a controlled, tension-managed manner.

- To feed a flat, consistent strip into the next machine, typically a straightener or a roll former.

The core principle involves mounting the coil on a mandrel (a expanding shaft or set of arms) and allowing it to rotate, feeding the leading edge of the metal strip into the downstream equipment. As the line pulls the material, the decoiler either freely releases it (in a drag or brake-driven system) or actively unwinds it (in a powered system) to maintain proper tension.

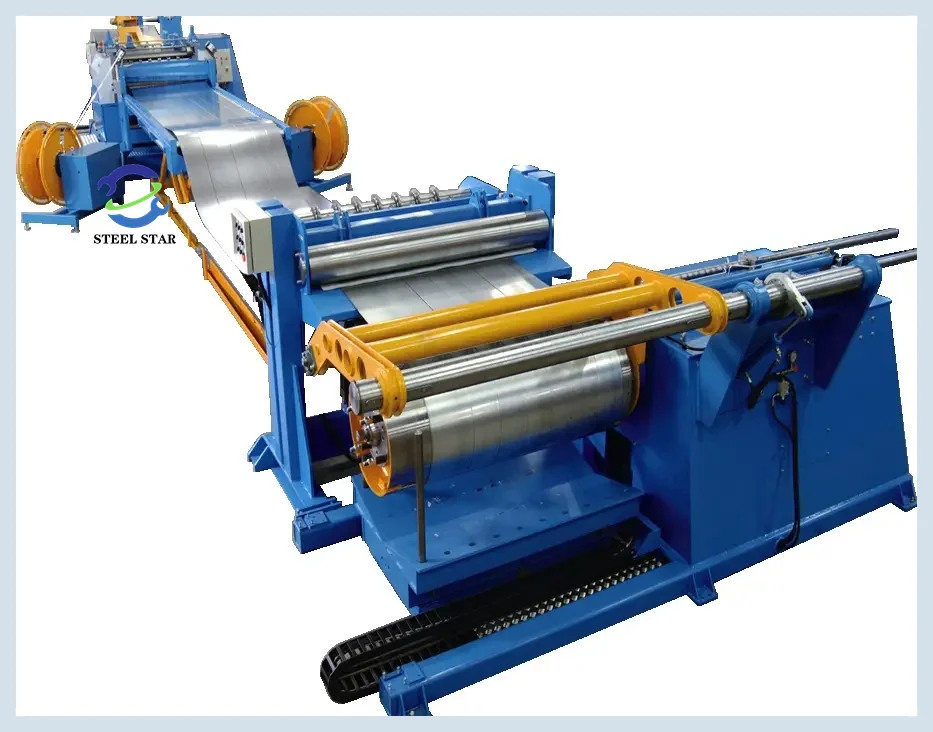

Key Components and Anatomy

A standard decoil machine consists of several vital components:

- Frame: A heavy-duty welded steel structure providing stability and support for heavy loads, often exceeding 20 tons.

- Mandrel: The central shaft that expands mechanically or pneumatically to grip the inside diameter of the coil, preventing slippage. It can be a single, double, or three-shaft design.

- Coil Car or Saddle (Optional but Common): A hydraulically operated platform that lifts the coil from the floor and aligns it with the mandrel for easy loading, dramatically improving safety and efficiency.

- Brake System: Critical for passive decoilers, it provides adjustable drag (through pneumatic, magnetic particle, or mechanical disc brakes) to create back tension, preventing the coil from overspinning and tangling.

- Drive Motor: In powered decoilers, an electric motor actively rotates the mandrel in sync with the production line’s speed, often controlled by a tension-sensing loop.

- Guide Arms or Side Supports: Adjustable arms that position the coil laterally, ensuring it feeds squarely into the line and prevents side-to-side wandering (“walking”).

- Peel-off Roller or Plate: A small roller or curved plate that helps separate and direct the leading edge of the metal upward as it unwinds.

Types of Decoilers

Decoil machines are engineered for specific applications and levels of automation:

- Manual or Passive Decoiler: The simplest type. The coil is placed on the mandrel, and a brake provides tension. The downstream machine pulls the material, causing the decoiler to unwind. Ideal for lighter gauges and lower-speed lines.

- Powered or Motorized Decoiler: Equipped with a drive motor that actively unwinds the coil. It is often integrated with a tension control system (using a dancer arm or load cell) to maintain precise, constant tension, which is crucial for processing delicate or high-strength materials.

- Double Head Decoiler: Features two mandrels, allowing an operator to load a new coil on one head while the other is feeding the line. This enables continuous, non-stop production, maximizing efficiency for high-volume operations.

- Cantilevered vs. Center-Shaft Decoiler: In a cantilevered design, the mandrel is supported from one side only, allowing for easy side-loading of coils. A center-shaft design supports the mandrel at both ends for handling extremely heavy, wide, or large-ID coils with greater stability.

Importance and Role in the Production Line

The decoiler’s performance is foundational. Any inconsistency at this stage propagates through the entire line.

- Ensures Process Stability: Proper tension control prevents material sagging, snagging, or stretching, which would cause defects in the final product.

- Enables Automation and Speed: Efficient decoiling, especially with coil cars and powered feeds, is the prerequisite for high-speed, automated manufacturing.

- Improves Safety: Mechanizing the handling of heavy, sharp-edged coils protects workers from manual lifting injuries.

- Optimizes Material Yield: Smooth, controlled feeding minimizes scrap at the line’s start-up and during running.

Applications Across Industries

Decoil machines are the universal first step in any coil-consuming process:

- Metal Roofing and Siding: Feeds coil into panel roll formers.

- Guardrail and Stud Manufacturing: Unwinds steel for structural roll-forming lines.

- Stamping and Blanking Press Lines: Feeds coil into high-speed presses for automotive parts or appliances.

- Slitting Lines: Unwinds master coils to be cut into narrower strips.

- Pipe and Tube Mills: Feeds strip steel into forming and welding mills.

The decoil machine is a paradigm of robust, focused engineering. It performs the vital, unsung task of beginning the transformation from raw coil to finished product. While it may lack the complex forming tools of a press or the programmed precision of a robot, its role as the stable, reliable feeder is irreplaceable. In the symphony of modern manufacturing, if the roll former or stamping press is the soloist, the decoil machine is the meticulous conductor, setting the precise tempo and flow for the entire performance. It is, without exaggeration, the essential first act in the drama of metal fabrication.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)