The Downspout Roll Forming Machine: Channeling Efficiency in Modern Fabrication

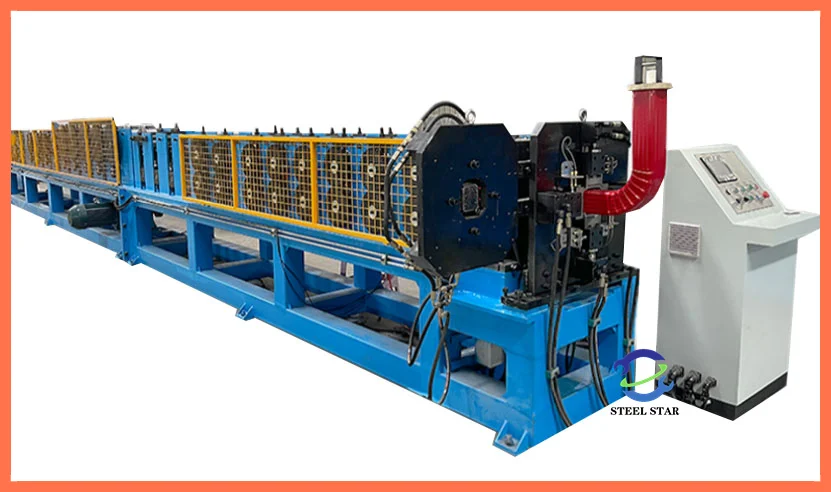

In the world of sheet metal fabrication for construction and drainage, the downspout roll forming machine stands as a critical piece of equipment. Its primary function is the continuous, high-volume production of downspouts (also called drainpipes, rainspouts, or leaders)—the vertical piping systems that channel rainwater from roof gutters safely to the ground or a drainage system.

This machine exemplifies the principle of cold roll forming, a process where a continuous coil of pre-finished metal (typically galvanized steel, Galvalume, aluminum, or PVC-coated materials) is progressively shaped at room temperature through a series of precisely engineered roller dies. Unlike single-stroke presses, roll forming creates a consistent, seamless profile over theoretically unlimited lengths, which are then cut to standard sizes (usually 10 or 20 feet).

Core Components and Process Flow:

A standard downspout roll forming line integrates several key stations into a synchronized system:

- Decoiler/Holder: This unit securely holds the heavy metal coil, feeding it smoothly into the line. Advanced systems may include automatic coil loading and stitching to join coils end-to-end for non-stop operation.

- Pre-Punching/Notching Station (Optional but Common): Before forming, a punching unit (often CNC-controlled) can pierce holes for screw fasteners, outlet spouts, or create decorative patterns. Pre-forming punching ensures higher accuracy than post-forming piercing.

- Roll Forming Mill: The heart of the machine. It consists of a sequential set of paired roller dies mounted on a sturdy frame. Each set of rollers incrementally bends the flat strip—first into a rough “U” shape, then gradually closing and forming the final seam (usually a Pittsburgh lock or a simple hooked seam) and the desired cross-section (like rectangular, round, or corrugated).

- Cut-Off System: A high-speed, servo-electric or hydraulic flying cut-off precisely shears the continuously moving formed downspout to pre-set lengths without stopping the line flow.

- Control System: A centralized PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) panel synchronize all components, controlling feed speed, cut length, punching patterns, and monitoring system diagnostics.

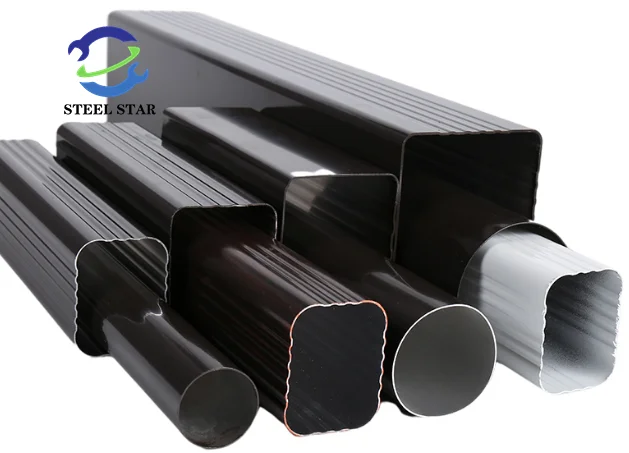

Profile Versatility and Tooling:

A significant advantage of these machines is their adaptability. By changing the set of roller dies (the tooling), a single machine can produce a variety of downspout shapes and sizes to match different architectural styles and gutter systems. Common profiles include:

- K-Style: The most common residential profile, with a decorative, corrugated face resembling crown molding.

- Half-Round: A smooth, semi-circular profile often used in more traditional or commercial architecture.

- Rectangular: A simple, box-like design for a modern, minimalist appearance.

The Competitive Edge: Benefits of Roll Forming

Compared to alternative methods like press braking or extrusion, roll forming for downspouts offers distinct advantages:

- High Speed & Volume: Capable of producing tens of meters per minute, it is ideal for mass production.

- Consistent Quality: Delivers uniform cross-sections and mechanical properties along the entire length with minimal variation.

- Material Efficiency: Minimal scrap is generated, especially when compared to cut-and-bend methods.

- Strength: The cold-working process slightly work-hardens the metal, enhancing the final product’s stiffness.

- Seamless Integration: Easily linked with auxiliary operations like punching, embossing, and automatic stacking.

Modern Advancements and Trends:

Today’s downspout roll formers are increasingly intelligent and efficient:

- Servo-Driven Technology: Provides exceptional accuracy in cut-length and punching registration, with faster response and lower energy consumption than traditional hydraulic systems.

- Quick-Change Tooling: Reduces downtime during profile changeovers, boosting overall equipment effectiveness (OEE).

- IoT Connectivity: Allows for remote monitoring of production data, predictive maintenance alerts, and integration into broader smart factory systems.

The downspout roll forming machine is a cornerstone of efficient metal component manufacturing. It transforms a flat metal coil into a finished, functional product ready for installation in a single, streamlined pass. Its reliability, speed, and flexibility make it indispensable for manufacturers supplying the construction industry, ensuring that buildings worldwide are equipped with durable, precise, and effective drainage systems. By continuously evolving with automation and precision engineering, this machine remains vital in meeting the demands of modern construction, channeling both rainwater and productivity with unmatched efficiency.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)