The Stud and Track Roll Forming Machine: The Engine of Modern Light Gauge Steel Construction

In the global shift towards faster, stronger, and more sustainable building methods, light gauge steel (LGS) framing has emerged as a dominant force. At the very core of this construction revolution lies a deceptively simple yet profoundly impactful machine: the Stud and Track Roll Forming Machine. This highly efficient system is responsible for mass-producing the fundamental building blocks—vertical studs and horizontal tracks—that form the load-bearing walls, partitions, and floor/ceiling assemblies in countless residential, commercial, and industrial structures.

More than just a metal bender, this machine is the starting point of a precision-engineered supply chain that enables modular construction, reduces on-site waste, and delivers structures of exceptional dimensional stability and strength. This article explores the technology, operation, and indispensable role of the stud and track roll forming machine.

1. The Product: Understanding Studs and Tracks

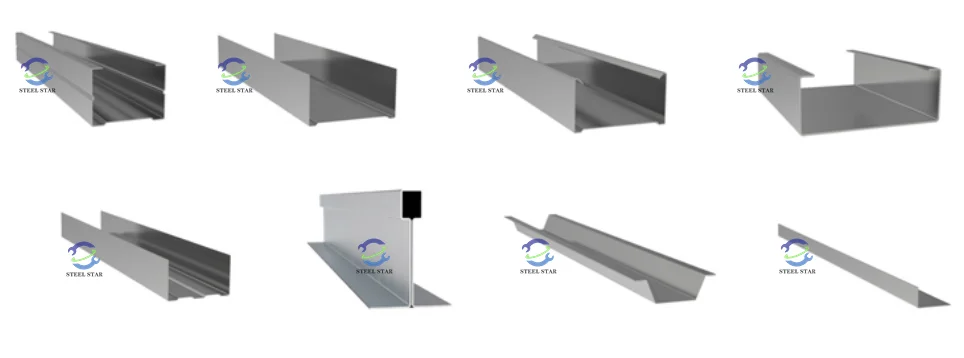

The machine produces two complementary, industry-standard cold-formed steel profiles:

- Studs: These are the vertical load-bearing members, typically C-shaped in cross-section. They feature a central web and two flanges, with a lip (or return) on each flange for added stiffness. They come in standard depths (e.g., 92mm, 146mm for 3.5″, 5.5″ wall cavities) and are pre-punched with large service holes to allow for the easy passage of electrical wiring and plumbing.

- Tracks: These are the U-shaped channels that cap the top and bottom of a wall assembly. Studs fit snugly inside them, and they are anchored to the floor and ceiling. Tracks are typically unpunched and provide a surface for securing wall finishes.

Together, studs and tracks form a modular, predictable, and incredibly strong skeleton for interior and exterior walls.

2. Machine Anatomy and Process Flow

A modern stud and track roll forming line is a model of continuous, automated production. The process follows this sequence:

1. Decoiling & Straightening:

A heavy-duty decoiler holds a large coil (3-5 ton) of galvanized steel strip. The strip passes through a precision leveling unit to remove any coil curvature or camber, ensuring it is perfectly flat—a critical step for forming accuracy.

2. Pre-Punching/Notching (The Defining Feature for Studs):

This is the most critical differentiating stage. For stud production, the flat strip enters a high-tonnage, CNC-controlled punching station. In a single, synchronized hit, this station performs multiple operations:

- Punches Service Holes: Creates the large, standardized openings in the web.

- Cuts End Notches: Forms the complex notches at each end of the stud, allowing it to fit securely into the track and providing flanges for screw fastening.

- Makes Pilot Holes: For additional screw attachments or alignment.

This pre-forming punching is vastly superior to post-forming methods and is key to the interoperability of LGS components.

3. The Roll Forming Mill:

The punched (or plain, for track) strip then enters the heart of the machine. It travels through a progressive series of forming stations (typically 12-18 pairs of rolls). Each set of hardened steel rollers makes an incremental bend. The process gradually transforms the flat strip into the final C or U shape with consistent thickness and geometry. The cold-working process increases the steel’s yield strength.

4. Cut-Off System:

A high-speed flying cut-off—almost universally a precise, servo-electric shear—cuts the continuously moving profile to exact, pre-programmed lengths. The system can instantly switch between standard lengths (e.g., 8′, 9′, 10′) or custom sizes.

5. Automatic Stacking and Bundling:

Finished studs or tracks are conveyed, automatically counted, aligned, and stacked into neat, strapped bundles. These are labeled with job information and prepared for direct shipment to a construction site or a panel fabrication shop.

6. The Control Center:

A centralized PLC and touchscreen HMI govern the entire line. Operators can select product recipes, input dimensions and quantities, and monitor production speed and diagnostics. Advanced systems integrate directly with Building Information Modeling (BIM) software, allowing the digital model to generate machine code.

3. Key Technological Advancements

- Quick-Change Tooling Systems: Modern machines allow for rapid switching between stud and track tooling sets, as well as between different stud depths (e.g., from a 92mm to a 146mm profile). This minimizes downtime and maximizes line flexibility.

- Servo-Electric Drive Technology: Replacing hydraulic systems with servo motors for the punch, rolls, and cut-off provides superior accuracy, energy efficiency, quieter operation, and easier maintenance.

- In-Line Flange Embossing: Some advanced lines can add small dimples or ribs to the stud flanges. This embossing significantly enhances axial load capacity by inhibiting buckling.

- IoT & Industry 4.0 Connectivity: Machines equipped with sensors enable predictive maintenance, remote monitoring, and data collection for optimizing Overall Equipment Effectiveness (OEE).

4. Impact on the Construction Industry

The stud and track machine is the foundational technology enabling:

- Panelized and Modular Construction: Components are mass-produced with perfect consistency, allowing for walls and floors to be pre-assembled in factories under controlled conditions before being shipped to site.

- Precision and Speed: On-site framing changes from a craft-based cutting and measuring process to a rapid, bolted assembly of pre-engineered parts, reducing construction timelines by 30-50%.

- Labor Optimization: It shifts skilled labor from the variable construction site to the controlled factory environment, helping to address skilled trade shortages.

- Sustainability: Steel is infinitely recyclable. The roll forming process generates less than 2% scrap, all of which is recycled, creating a near-zero-waste fabrication stream.

5. Considerations for Fabricators

Investing in a production line requires careful evaluation:

- Profile Range: Defining the required gauges (thicknesses), depths, and flange widths.

- Material Strength: Machines are rated for specific steel yield strengths (e.g., G550, 550 MPa).

- Level of Automation: Choices range from basic manual decoiling to fully automated lines with coil stitching and robotic stacking.

- Tooling Life and Support: The quality of the roll and punch tooling, along with access to technical service, is critical for long-term profitability.

The stud and track roll forming machine is far more than a piece of factory equipment. It is the essential first link in a value chain that is redefining resilience, efficiency, and quality in the built environment. By transforming raw steel coil into the standardized, intelligent components of a building’s skeleton, it provides the literal framework for faster, greener, and more dependable construction.

As urbanization and the demand for high-quality housing and commercial space accelerate globally, this machine’s role becomes ever more central. It stands as a testament to industrialized construction, quietly and relentlessly producing the precision bones upon which modern societies are built.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)