The Roof Panel Roll Forming Machine: Precision Engineering for Modern Construction

In the realm of modern construction and architectural cladding, efficiency, consistency, and strength are paramount. The roof panel roll forming machine stands as a cornerstone technology, transforming raw coils of metal—typically steel, aluminum, or zinc—into high-performance, precisely shaped roofing profiles with remarkable speed and accuracy. This specialized machinery is indispensable for manufacturers serving the residential, commercial, and industrial building sectors.

Core Function and Process

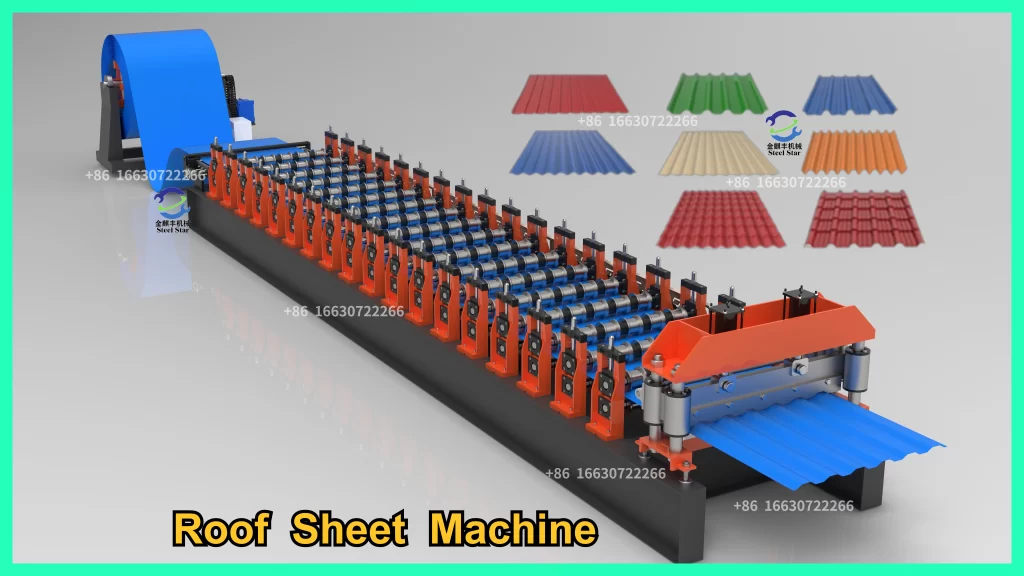

A roll forming machine is a continuous, linear fabrication system. Its fundamental operation involves progressively shaping a flat metal strip into a desired cross-sectional profile through a series of roller dies (stations). For roof panels, this process begins with an uncoiler that holds the large metal coil. The strip is fed through a pre-piercing or pre-cutting station (if required for features like vent holes) and then into the sequential roll forming stations.

Each set of powered, contoured rollers bends the metal incrementally, gradually forming the complex contours of the final panel—such as standing seams, trapezoidal ribs, or batten profiles—without compromising the material’s integrity. After forming, the panel passes through a cutting mechanism (flying cut-off saw or shear) that precisely cuts it to the required length without halting the line, ensuring a continuous production flow. The finished panels are then automatically stacked for packaging and shipment.

Key Advantages and Output

The benefits of using a dedicated roll forming machine for roof panels are significant:

- High-Speed Production: Capable of producing tens of meters of panel per minute, far outpacing traditional sectional or press braking methods.

- Exceptional Consistency: Every panel produced is identical, ensuring uniform appearance, fit, and performance across an entire roof installation. This repeatability is critical for waterproofing and structural integrity.

- Material Efficiency: Minimizes waste through precise control and the ability to pre-cut to exact project lengths.

- Profile Flexibility: Modern machines, often CNC-controlled, can produce a vast array of complex profiles with tight tolerances. Quick-change roller systems allow for switching between different panel designs with minimal downtime.

- In-line Integration: The process can be seamlessly integrated with additional operations like embossing, painting, sealing bead application, or even insulation bonding, creating a complete panel system in one pass.

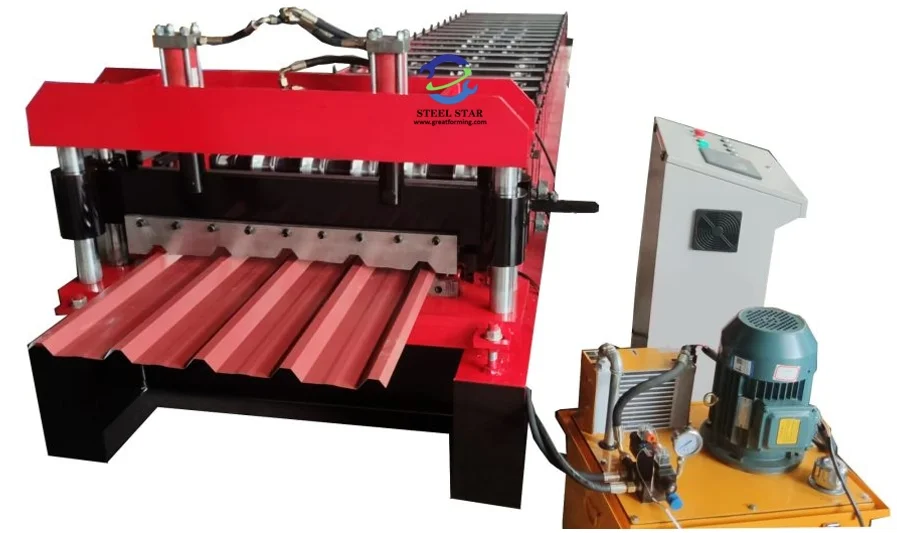

Machine Configuration and Technology

A sophisticated roof panel roll forming line comprises several integrated components:

- Decoiler & Straightener: Presents the metal coil and removes coil curvature.

- Feed & Servo Control: Precisely meters the material into the forming section.

- Roll Forming Mill: The heart of the machine, consisting of a series of stands housing the contoured tooling rollers. The number of stands depends on the profile’s complexity.

- Cut-Off System: A flying cut-off synchronized with the panel’s movement for burr-free, accurate lengths.

- Run-Out Table & Stacker: Handles and stacks the finished panels automatically.

- PLC Control System: The brain of the operation, managing speed, length, cut positions, and diagnostics for optimal performance and ease of use.

Applications and Impact

The panels produced are used for:

- Standing Seam Roofs: Popular for their exceptional weathertightness and modern aesthetic.

- Corrugated & Trapezoidal Roofing: Widely used in industrial and agricultural buildings.

- Tile-Effect & Shingle Panels: Offering the look of traditional materials with metal’s durability.

- Composite Insulated Panels: Where the machine forms the metal facings for sandwich panels.

By enabling the cost-effective mass production of high-quality, durable roofing components, the roll forming machine directly supports advancements in building envelope technology, energy efficiency (through reflective coatings and integrated solar panel readiness), and architectural design freedom.

The roof panel roll forming machine is a quintessential example of advanced manufacturing meeting the demands of the construction industry. It transcends simple metal bending, representing a fully automated, precise, and highly adaptable production solution. As architectural trends evolve and the demand for sustainable, long-lasting building materials grows, this machinery continues to evolve, solidifying its role as a vital tool in shaping the skylines of the future. Its ability to combine speed with precision makes it an irreplaceable asset for any manufacturer aiming to lead in the competitive metal roofing supply market.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)