The roofing industry, traditionally reliant on manual labor and slow, arduous processes, has been fundamentally transformed by the advent of specialized roofing machines. These technologies are not mere incremental improvements; they represent a shift towards greater efficiency, enhanced safety, superior quality, and cost-effectiveness in constructing the building envelope.

The Core Types and Their Functions

Roofing machines can be broadly categorized by their primary function:

- Material Handling and Deployment: This is the most impactful category. Roofing Rollers and Unrolling Machines are now indispensable for single-ply membranes (like TPO, PVC, and EPDM). They precisely guide and lay massive rolls of material, ensuring wrinkle-free, consistent application at speeds impossible to achieve manually. For modified bitumen systems, Torch Application Rollers provide a controlled, safe method for heat-welding sheets, significantly reducing fire risks compared to hand-held torches.

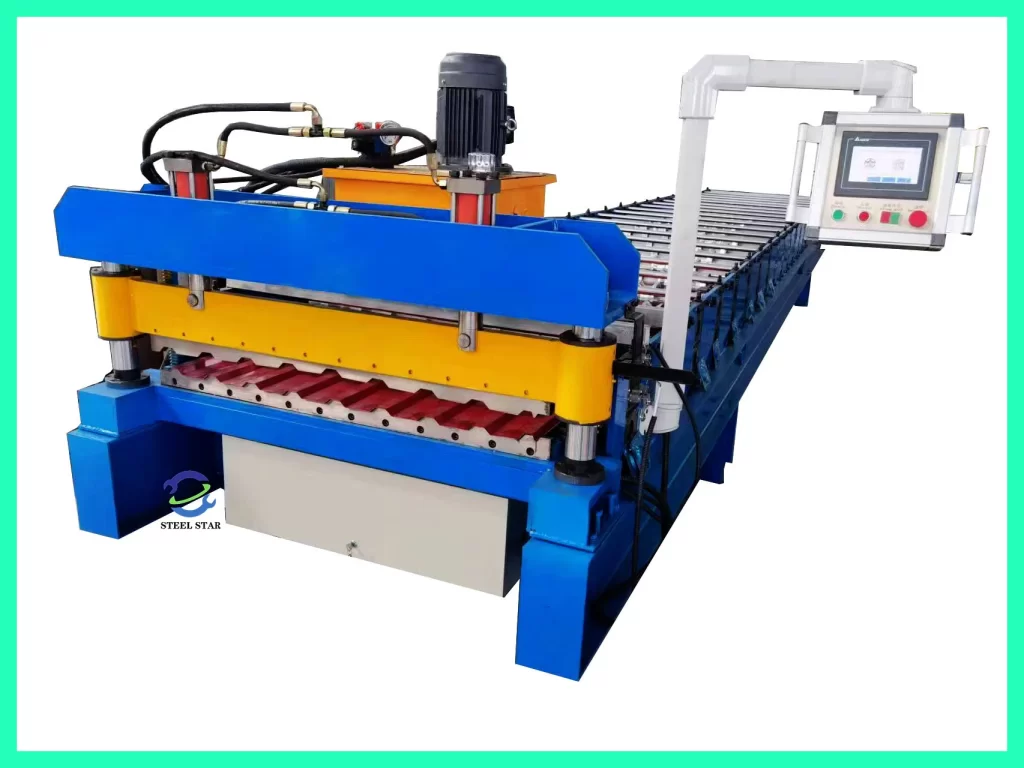

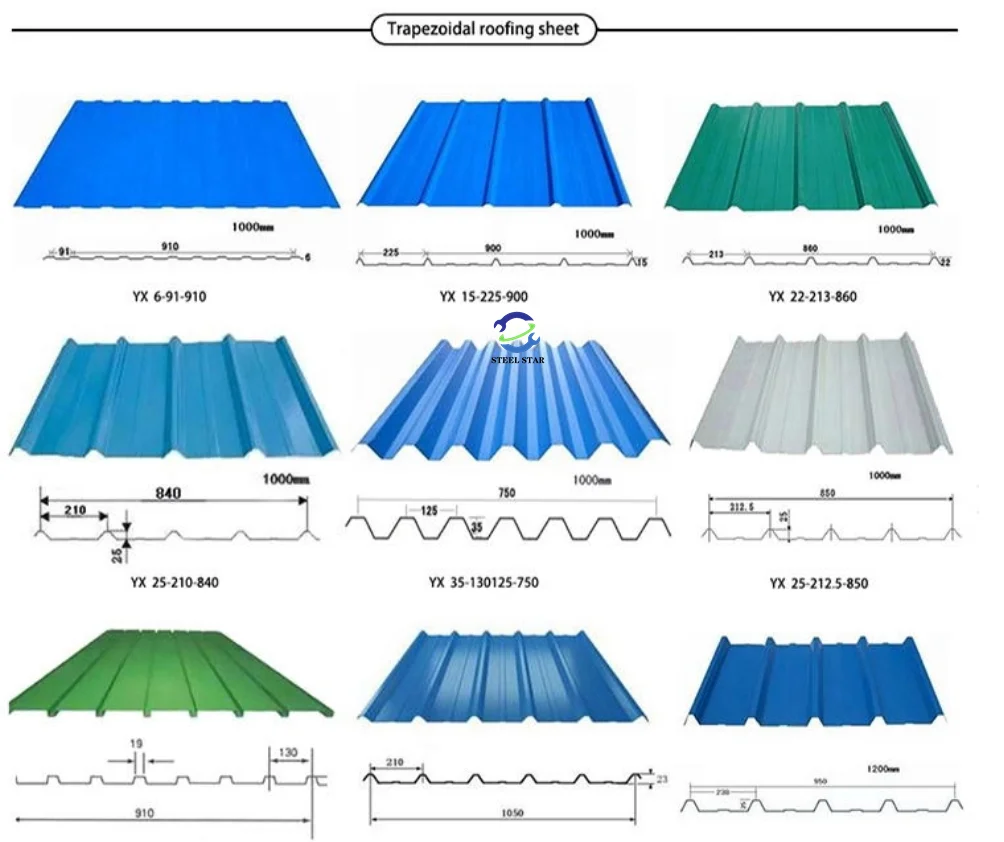

- Fastening and Seaming: Precision and speed are critical here. Automatic Screw Fasteners and Coil-fed Nailers are pneumatic or electric tools that drive fasteners at a set depth and spacing with trigger-pull speed. This ensures consistent wind uplift resistance and dramatically reduces installer fatigue. For metal roofing, Seam Formers and Panel Benders create uniform, watertight standing seams on-site, ensuring structural integrity and a clean aesthetic.

- Surface Preparation and Finish: A proper roof begins with a solid deck. Adhesive Spreaders apply bitumen or other adhesives in an even layer, optimizing bond strength and material usage. For gravel or stone ballast on flat roofs, Gravel Spreaders distribute aggregate evenly and safely, protecting the membrane beneath.

- Material Production (On-site): Some systems bring manufacturing to the roof. Polyurethane Foam Spray Rigs combine chemical components to spray-install seamless, highly insulating foam roofs. Granule Sprayers immediately embed protective chips into hot asphalt or adhesive during application, enhancing durability and reflectivity.

The Undeniable Benefits

The adoption of these machines delivers clear advantages:

- Unmatched Efficiency and Productivity: Machines complete tasks in a fraction of the time. A crew can unroll and loosely lay thousands of square feet of membrane in minutes, allowing them to focus on critical seaming and detailing.

- Enhanced Quality and Consistency: Automated processes minimize human error. Fastener depth, seam width, adhesive spread, and material alignment are consistently maintained, leading to a more reliable, high-performance roof system that meets stringent manufacturer specifications.

- Improved Worker Safety: By reducing repetitive strenuous movement (lifting heavy rolls, constant hammering, bending) and automating high-risk tasks (torch application), machines lower the incidence of musculoskeletal injuries and accidents. This creates a safer worksite.

- Long-term Cost Savings: While requiring initial investment, the reduced labor time, lower material waste (via precise application), and fewer call-backs for repairs due to superior installation quality lead to a better bottom line for contractors and building owners alike.

The transition to machine-reliant roofing is not without challenges. Initial capital costs can be high for smaller contractors. Machines also add complexity, requiring operator training and regular maintenance. Furthermore, they are best suited for large, open commercial and industrial flat or low-slope roofs; their utility on complex, steeply-pitched residential roofs is currently more limited.

Looking ahead, the future points towards further innovation. The integration of GPS and robotic guidance systems for fully automated material laying is on the horizon. Telematics in machines will provide real-time data on performance and maintenance needs. The drive for sustainability is also pushing the development of equipment designed for new, eco-friendly materials like advanced synthetic polymers and recycled-content products.

In conclusion, roofing machines have moved from being niche tools to central pillars of modern roofing practice. They empower contractors to deliver projects faster, safer, and to a higher standard. As technology continues to evolve, these machines will further define the industry, pushing the boundaries of what is possible in protecting the structures beneath our feet from the elements above. The roof overhead is increasingly a product of sophisticated engineering, both in its materials and in the machinery used to install it.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)