In the vast ecosystem of industrial metalworking, the slitting line machine stands as a critical and highly efficient workhorse. Its primary function is deceptively simple: to longitudinally cut wide coils of metal—such as steel, stainless steel, aluminum, or copper—into multiple narrower strips of precise widths. This fundamental process is indispensable for transforming bulk raw material into the specific sizes required by countless downstream manufacturing sectors.

Core Components and Workflow

A modern slitting line is an integrated system of synchronized components, each playing a vital role:

- Pay-off Reel (Uncoiler): This holds and feeds the master coil into the line. It applies controlled back tension to prevent material slack.

- Entry Guide and Flattener: This section aligns the strip and often incorporates leveling rolls to remove coil set or crossbow, ensuring flat material enters the cutting zone.

- The Slitting Head: The heart of the machine. Here, two sets of hardened steel circular knives—one set on the top arbor (driven) and one on the bottom arbor (idler)—perform the cut. The precise spacing of these knives, set according to a slitter setup chart, determines the final strip widths. Key slitter types include:

- Loop (Pull-Through) Slitting: The simplest, where material is pulled through stationary slitter arbors.

- Wrapped (Drive) Slitting: The metal wraps around the motor-driven top arbor, providing positive drive for thicker or harder materials, offering better accuracy and surface finish.

- Separator System (Stripper): After slitting, the nested strips must be separated. This is typically done with a series of pins or plates to prevent inter-edge scratching.

- Tension Stand & Pull Rolls: These grip the strips and pull them through the line at a controlled, consistent speed, maintaining process stability.

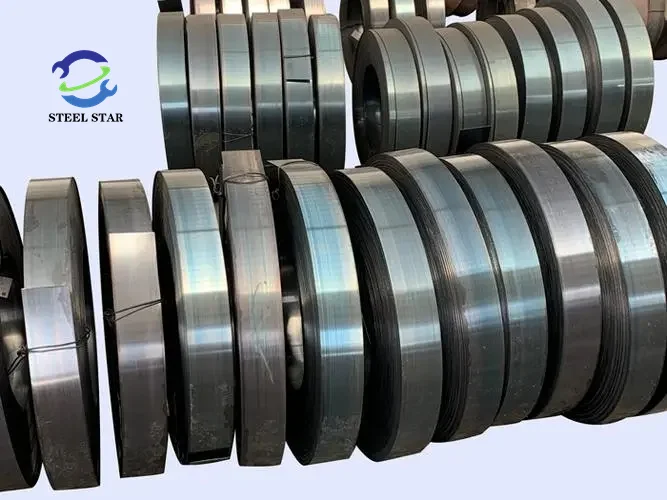

- Recoiler: The final station, where the individual narrow strips are rewound onto separate mandrels. A sophisticated edge-guiding system ensures tight, parallel winding.

- Scrap Winders: Integrated systems to coil the thin edge trim, a byproduct of the slitting process, for efficient recycling.

Key Advantages and Industry Impact

The adoption of automated slitting lines delivers profound benefits over older, manual cutting methods:

- Unparalleled Efficiency & Productivity: A modern line can process a 20-ton coil in minutes, producing dozens of perfect strips simultaneously, drastically outperforming single-cut methods.

- Precision and Consistency: CNC-controlled knife positioning and tension control yield strips with exact widths and flawless, burr-minimized edges. This dimensional accuracy is crucial for automated downstream processes like stamping or roll-forming.

- Material Optimization: By slitting to exact customer specifications, service centers minimize waste, maximizing yield from the master coil.

- Improved Safety: Automated handling of heavy coils and enclosed cutting areas significantly reduce manual labor hazards.

- Economic Imperative: For metal service centers, slitting is a core value-added service. It bridges the gap between mill production (optimized for wide, heavy coils) and manufacturer needs (specific, manageable strip sizes).

Applications Across Manufacturing

The output of slitting lines feeds into a staggering array of industries:

- Automotive: Strips for seat frames, bracketry, and trim.

- Construction: Studs, tracks, and framing components.

- Appliance & HVAC: Ductwork, casings, and internal components.

- Pipe & Tube Mills: Narrow strip (skelp) is the feedstock for welded tube production.

- Electronics: Precision strips for enclosures and connectors.

Technological Evolution and Future Trends

Today’s slitting lines are marvels of automation. Computer Numerical Control (CNC) manages knife positioning, line speed, and tension. Advanced Proportional-Integral-Derivative (PID) loop systems ensure perfect winding. Future trends point toward even greater connectivity, with Industrial Internet of Things (IIoT) sensors enabling predictive maintenance by monitoring vibration, temperature, and knife wear. Integration with factory-wide Manufacturing Execution Systems (MES) allows for seamless job tracking and data analytics to optimize overall equipment effectiveness (OEE).

The slitting line machine is far more than a simple cutter. It is a sophisticated, precision-engineered system that forms the essential link between primary metal production and finished goods manufacturing. By delivering material in the exact required form, it enables the speed, efficiency, and quality that define modern industrial production. Its continuous evolution in automation and control underscores its enduring role as a foundational pillar of the metalworking industry.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)