Gutter Machinery: Precision Manufacturers of Modern Building Drainage Systems

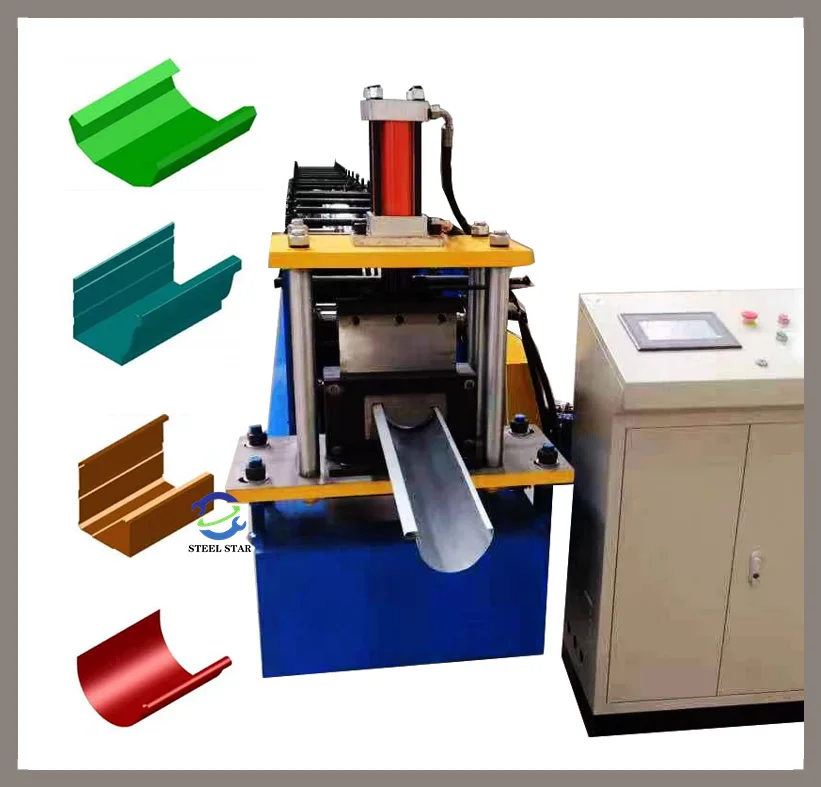

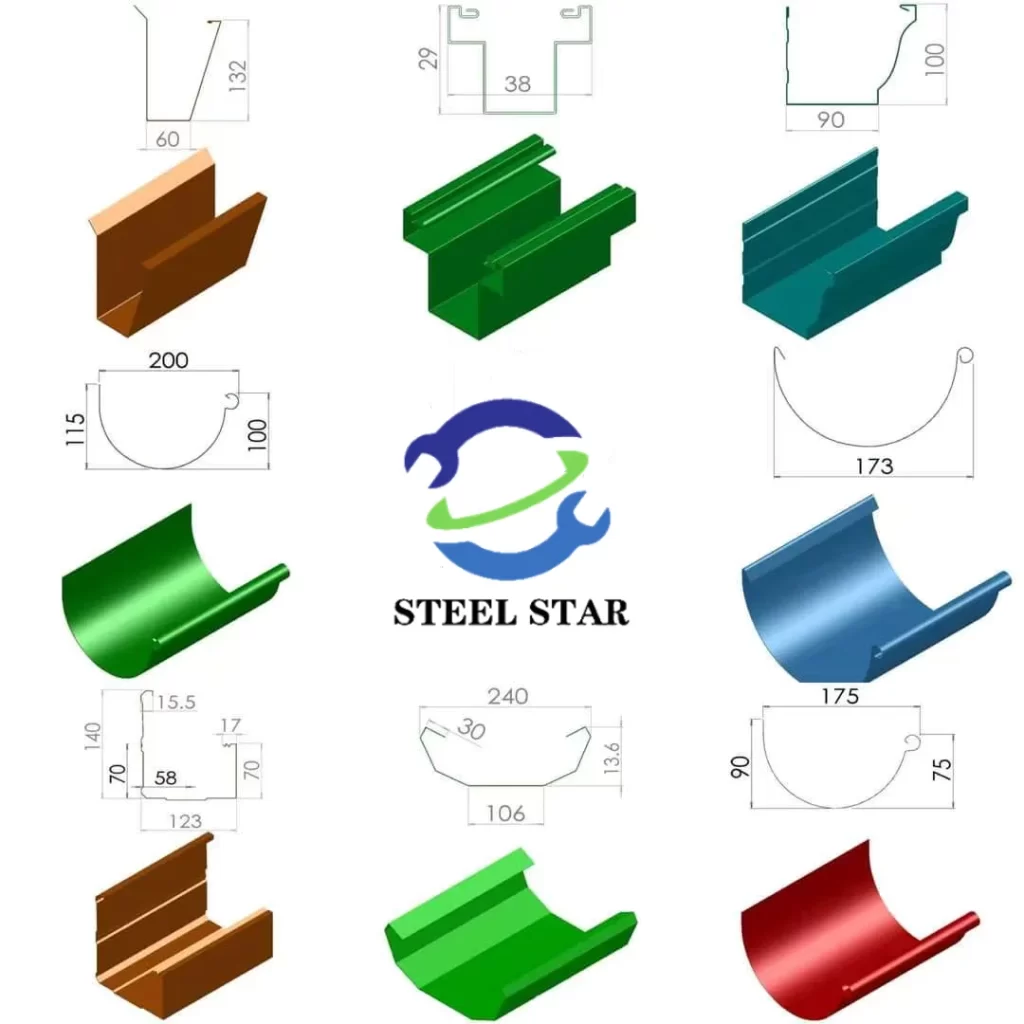

Gutter machinery consists of specialized industrial equipment used to produce gutters for building drainage systems. These machines utilize automated processes to shape metal coils or plastic profiles into gutter products with specific cross-sectional shapes and functions. With the construction industry’s increasing demands for efficiency, precision, and customization, gutter machinery has become an indispensable key piece of equipment in the building materials manufacturing field.

I. Main Types and Working Principles

1. Classification by Processed Material:

- Metal Gutter Machinery: Primarily handles metal materials such as galvanized steel, aluminum, copper, and stainless steel. It employs cold bending forming technology, gradually forming the desired cross-sectional shape through multiple rolling processes.

- Plastic Gutter Machinery: For plastic materials such as PVC and polypropylene, it typically uses extrusion molding processes, combined with subsequent cooling, cutting, and punching processes.

2. Classification by Automation Level:

- Fully Automated Production Line: Integrates uncoiling, forming, punching, cutting, and bending into one continuous production line, producing 6-12 meters of finished product per minute.

- Semi-Automatic Equipment: Requires manual assistance with feeding and unloading, suitable for small-batch, multi-variety production.

- Portable On-Site Manufacturing Machine: Allows for direct production on construction sites, reducing transportation costs, and is particularly suitable for large projects or remote areas.

3. Core Technology Process:

- Material Pre-treatment: Uncoiling, leveling, and surface cleaning

- Roll Forming: Gradually forming the trough shape using 8-16 forming rollers

- Online Punching: Precisely punching out drainage holes and connection holes

- Fixed Length Cutting: CNC cutting to the preset length

- End Forming: Manufacturing connecting joints and end caps

II. Technical Features and Advantages

1. High-Precision Manufacturing: Modern rainwater trough machinery is equipped with a digital control system, achieving dimensional accuracy of ±0.5 mm, ensuring interchangeability and ease of installation for each component. Laser positioning and servo drive technology further enhance processing precision.

2. Significantly Improved Production Efficiency: Fully automated production lines can produce 2000-5000 meters of standard rainwater troughs daily, 30-50 times more efficient than traditional manual manufacturing. A quick mold change system allows for switching between different specifications within 15 minutes.

3. Optimized Material Utilization

Through optimized nesting algorithms and CNC cutting, material utilization can reach over 95%, significantly reducing raw material waste. Some advanced equipment can also achieve online recycling of scrap materials.

4. Multifunctional Integration

The new generation of equipment integrates multiple functions:

- Online spraying or coating system

- Automatic quality inspection (visual recognition system)

- QR code/barcode marking

- Intelligent packaging and stacking

5. Energy-Saving and Environmentally Friendly Features

Utilizing high-efficiency motors and frequency conversion control, energy consumption is reduced by 40% compared to traditional equipment. A closed lubrication system and dust collection device reduce environmental pollution.

III. Technical Parameters and Performance Indicators

Typical Technical Specifications of Metal Gutter Machinery:

- Processing Material Thickness: 0.4-1.2 mm

- Maximum Processing Width: 200-600 mm

- Production Line Speed: 8-25 m/min

- Power Requirements: 380V three-phase power, 30-100 kW

- Equipment Dimensions: Length 10-25 m, Width 2-3 m

- Control Method: PLC + Touch Screen, Industrial Computer Optional

IV. Market Applications and Development Trends

1. Expanding Application Areas

In addition to traditional residential buildings, gutter machinery products are widely used in:

- Commercial buildings and industrial parks

- Public facilities (schools, hospitals, stadiums)

- Historical building restoration projects

- Agricultural greenhouses and storage facilities

2. Technological Innovation Trends

- Intelligent Upgrade: IoT technology enables remote monitoring and preventative maintenance

- Flexible Manufacturing: The same equipment can produce various cross-sectional shapes and sizes

- Green Manufacturing: Compatible with renewable materials and environmentally friendly coating processes

Modular Design: Functional modules can be flexibly configured according to production needs

3. Market Development Dynamics The global rain gutter machinery market is growing at an average annual rate of 4-6%, with the Asia-Pacific region being the fastest-growing market. Customized, high-efficiency, and environmentally friendly equipment is favored by the market.

V. Equipment Selection and Usage Recommendations

1. Equipment Selection Considerations:

- Expected production volume and product types

- Raw material type and thickness range

- Factory space and infrastructure conditions

- Investment budget and payback period requirements

- Local technical support and after-sales service

2. Operation and Maintenance Key Points:

- Operators must receive professional training

- Regularly inspect and replace forming rollers

- Keep the lubrication system clean and effective

- Establish a preventative maintenance plan

- Maintain complete production records and quality data

3. Safety Precautions:

- Install necessary protective devices and emergency stop systems

Ensure electrical systems meet safety standards

Develop equipment operating procedures and emergency plans

Conduct regular safety inspections and risk assessments

VI. Industry Challenges and Future Outlook

The main challenges currently facing the industry include fluctuating raw material prices, a shortage of skilled personnel, and increasingly stringent environmental regulations. Future development will focus on:

- Digital and networked production management

- Application of artificial intelligence in quality inspection

- More energy-efficient and environmentally friendly manufacturing processes

- Equipment development adapted to new building materials

- Improvement of the global service network

Technological advancements in rainwater gutter machinery have not only improved product manufacturing efficiency and quality but also propelled the entire building drainage system towards greater reliability, durability, and aesthetics. With the increasing prevalence of smart and green buildings, rainwater gutter manufacturing technology will continue to innovate, providing the construction industry with more comprehensive solutions.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)