Roof Curving Machine: Engineering Curves into Modern Architecture

Introduction

Roof curving machines represent a specialized class of industrial equipment that transforms flat metal panels or structural components into precisely curved profiles for architectural and construction applications. These machines enable the creation of curved roofs—a design feature increasingly sought after in contemporary architecture for its aesthetic appeal, aerodynamic performance, and structural efficiency. From sports arenas and airport terminals to artistic cultural centers and modern residential designs, curved roofs define skylines while providing functional advantages.

Technical Principles and Machine Types

Operating Fundamentals

Roof curving machines operate on mechanical bending principles, applying controlled force to metal sheets or sections to achieve desired curvature without compromising material integrity. The process typically maintains the material’s thickness while elongating its outer surface and compressing its inner surface through plastic deformation.

Primary Machine Configurations

1. Three-Roll Plate Bending Machines (Pyramid and Initial Pinch Types)

- Pyramid Configuration: Features two lower fixed rolls and one adjustable top roll

- Initial Pinch Design: Utilizes two driven lower rolls and one adjustable top roll

- Capabilities: Can produce conical curves and cylindrical segments

- Typical Capacity: 1-50mm thickness for steel plates up to 4 meters wide

2. Four-Roll Bending Systems

- Advantages: Reduced flat ends on curved sections

- Operation: One upper roll, one lower roll, and two side rolls

- Applications: Heavy-duty industrial curved roofing components

3. Section Curving Machines

- Specialized for structural shapes (I-beams, channels, angles)

- Incremental bending through multiple pressure points

- Essential for curved support structures beneath curved roof panels

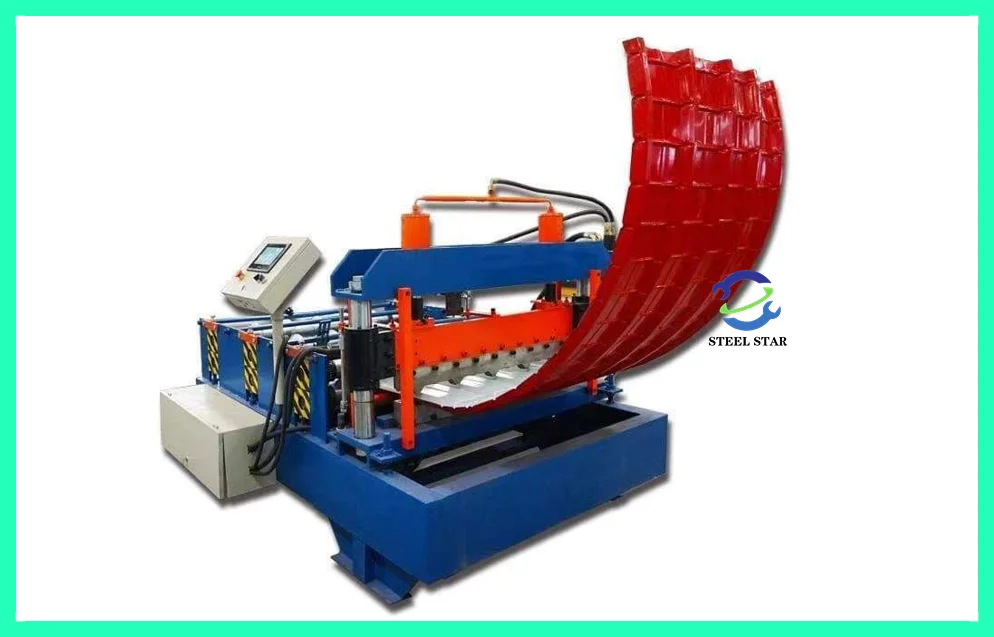

4. Roll Forming with Integrated Curving

- Combines profile forming and curvature in continuous process

- Produces curved standing seam panels directly from coil stock

- Most efficient for large-volume curved panel production

Key Components and Systems

Mechanical Structure

- Heavy-welded steel frame with stress-relieved construction

- Precision-machined rollers (60-65 HRC surface hardness)

- Hydraulic or electromechanical adjustment systems

- Computer-controlled crowning compensation systems

Control and Measurement Systems

- CNC controllers with curvature programming

- Laser measurement for real-time radius verification

- Force monitoring sensors for consistent bending

- Digital angle and position encoders

Material Handling Integration

- Powered infeed conveyors with alignment guides

- Crane-assisted loading systems for heavy plates

- Robotic part manipulation for complex curves

- Outfeed supports for curved component handling

Technical Specifications and Performance Parameters

Standard Machine Capacities:

- Maximum plate width: 1,500-6,000 mm

- Material thickness range: 0.8-30 mm (mild steel equivalent)

- Minimum achievable radius: 15-50 × material thickness

- Bending speed: 0.5-5 meters per minute

- Power requirements: 15-150 kW depending on size

- Positioning accuracy: ±0.1-0.5 mm

Applications in Modern Construction

Architectural Projects

- Curved standing seam roof systems

- Barrel vault roofs and arched structures

- Complex double-curvature roofs (hyperbolic paraboloids)

- Canopy and awning curved elements

Specialized Structures

- Aircraft hangars and maintenance facilities

- Sports stadium roofs and grandstand coverings

- Transportation hub roofs (airports, train stations)

- Industrial curved roof structures

Material Compatibility

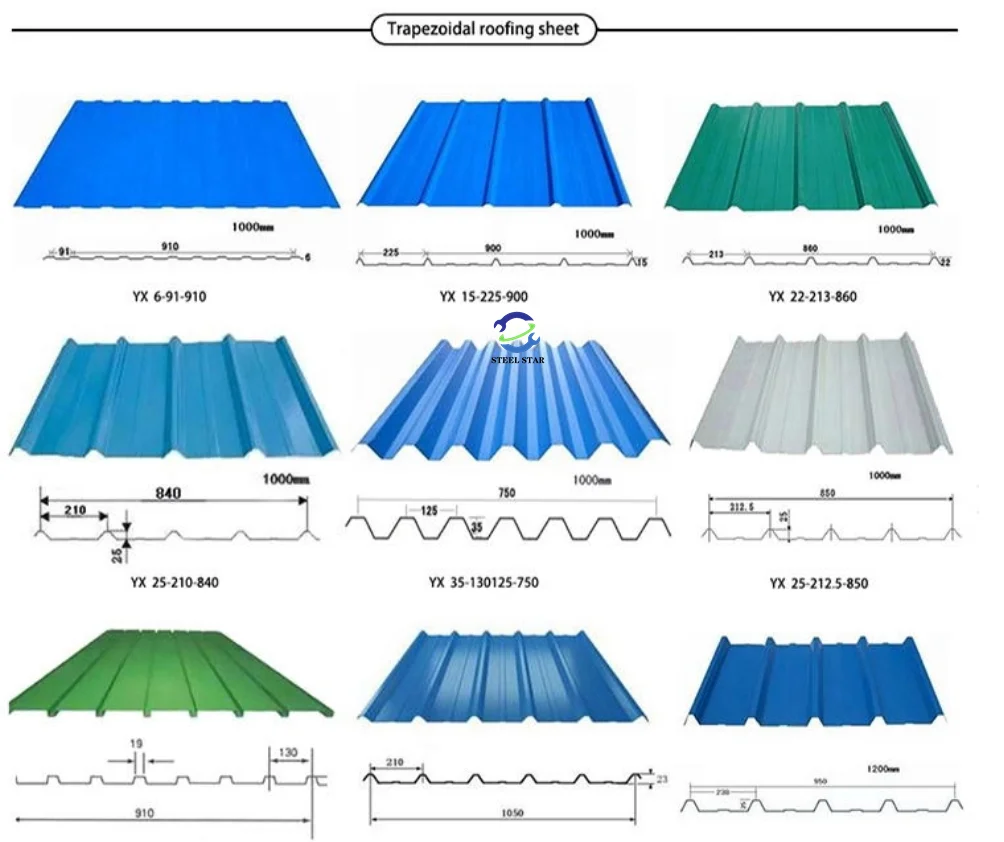

- Carbon steel (galvanized, pre-painted)

- Stainless steel (various grades)

- Aluminum alloys (architectural grades)

- Copper and zinc-titanium alloys

- Composite metal panels

Advantages Over Traditional Methods

Precision and Consistency

- Digital control ensures repeatable curvature

- Eliminates variations from manual processes

- Maintains material properties through controlled deformation

Production Efficiency

- 300-500% faster than manual hammer forming

- Reduced setup time for multiple identical components

- Continuous processing capability with automatic feeds

Material Optimization

- Minimal material waste compared to cutting from curved blanks

- Reduced secondary processing requirements

- Consistent mechanical properties throughout curved sections

Design Flexibility

- Quick changeover between different radii

- Ability to produce variable radius curves

- Capability for compound curvature in advanced systems

Technological Innovations

Advanced Control Systems

- 3D CAD/CAM integration for direct programming

- Simulation software predicting springback and deformation

- Adaptive control adjusting for material property variations

- Network connectivity for remote monitoring and diagnostics

Hybrid Manufacturing Approaches

- Combined laser cutting and curving in single machine

- Robotic bending cells for complex free-form shapes

- Integrated measurement and correction systems

- Automated tool changing for different profile types

Smart Manufacturing Features

- Force feedback for material property characterization

- Automatic calibration and alignment systems

- Predictive maintenance based on operational data

- Energy recovery systems in hydraulic power units

Operational Considerations

Installation Requirements

- Foundation specifications: Reinforced concrete up to 2 meters depth

- Floor space: 50-200 square meters depending on machine size

- Crane capacity: 5-50 tons for material handling

- Environmental controls: Temperature and humidity stabilization

Safety Systems

- Light curtain perimeter protection

- Two-hand operation controls

- Emergency stop circuits with monitoring

- Load sensing and overload protection

- Interlocked guarding systems

Maintenance Protocols

- Daily inspection of hydraulic systems and roll surfaces

- Weekly lubrication of all moving components

- Monthly alignment verification

- Annual comprehensive inspection and calibration

Industry Trends and Market Position

Current Market Landscape

The global market for architectural metal curving equipment is estimated at $380 million annually, with projected growth of 6.2% CAGR through 2028. Demand is driven by architectural trends favoring organic forms and the construction industry’s increasing capability to execute complex designs.

Sustainability Developments

- Energy-efficient drive systems reducing power consumption

- Compatibility with recycled metal content

- Reduced material waste through precise forming

- Longer tool life through advanced surface treatments

Future Directions

- Increased integration with BIM (Building Information Modeling)

- Development of machines for new composite materials

- Enhanced automation reducing manual intervention

- Portable systems for on-site curved panel production

- AI-assisted process optimization reducing trial-and-error

Selection and Implementation Guidelines

Technical Evaluation Factors

- Required curvature range and accuracy specifications

- Material types and thicknesses to be processed

- Production volume and throughput requirements

- Available facility space and utilities

- Operator skill level and training availability

Financial Considerations

- Typical ROI period: 2-4 years for moderate production

- Operating cost components: Energy, maintenance, tooling

- Potential savings from reduced labor and material waste

Vendor Assessment Criteria

- Industry experience with similar applications

- Technical support and training offerings

- Spare parts availability and lead times

- Software update and upgrade policies

- Reference installations and customer testimonials

Roof curving machines embody the convergence of mechanical engineering, materials science, and digital control technology that enables modern architecture’s most striking curved forms. These sophisticated systems transform flat metal into flowing architectural elements with precision, efficiency, and repeatability unattainable through traditional methods. As architectural expression continues to evolve toward more organic, fluid forms, and as construction methodologies advance toward greater prefabrication and precision, roof curving technology will remain essential for translating visionary designs into buildable realities. The ongoing development of smarter, more flexible, and more sustainable curving equipment promises to further expand architectural possibilities while improving construction efficiency—ensuring that the dramatic curved roofs that define contemporary landmarks will continue to be both economically feasible and structurally sound. In this context, roof curving machines are not merely manufacturing tools but enablers of architectural progress, bridging the gap between creative vision and practical execution in the built environment.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)