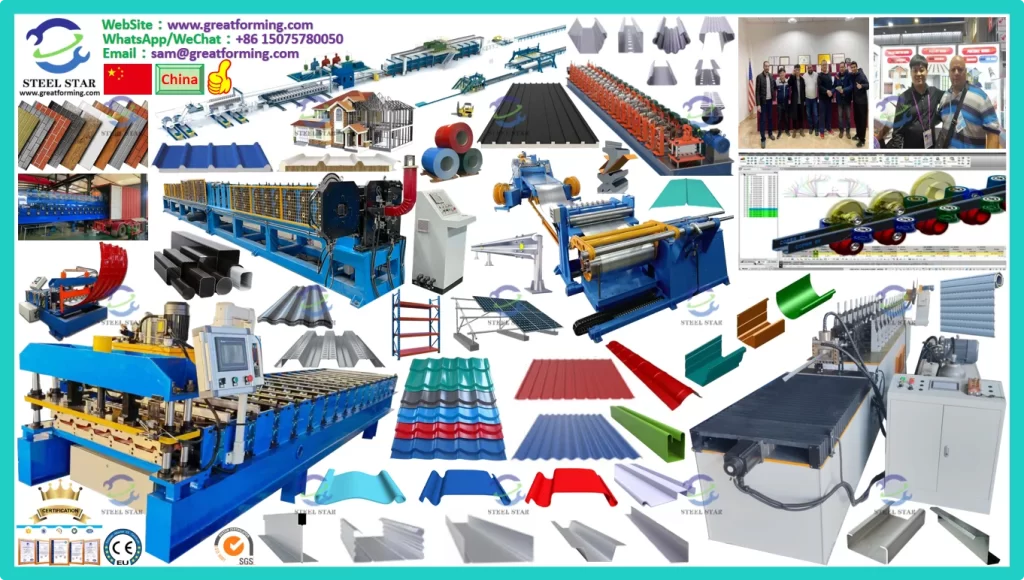

Steel Star Machine: 15 Years of Excellence in Roll Forming Technology

In the specialized world of industrial manufacturing, longevity and expertise are the true marks of quality. For 15 years, Steel Star Machine has established itself as a significant name in the design and production of roll forming machines, carving a niche through innovation, reliability, and deep customer partnership.

Roll forming is a continuous, high-volume metal shaping process that transforms coils of steel, aluminum, or other metals into consistent, complex cross-sectional profiles. It is the backbone of industries producing everything from construction panels and automotive parts to shelving and door frames. Over the past decade and a half, Steel Star Machine has refined this craft, evolving from a capable manufacturer into a trusted solutions provider.

The journey of these 15 years reflects a story of technological adaptation. Early models focused on robust mechanical durability and core precision. Today, a Steel Star roll forming line is a symphony of integrated engineering. It features advanced servo-driven technology for exceptional accuracy, quick-change cassette systems that slash downtime during profile changeovers, and sophisticated PLC controls with touch-screen HMI (Human-Machine Interface) for intuitive operation. This evolution directly addresses industry demands for greater flexibility, shorter runs, and more customized products without sacrificing speed or quality.

A cornerstone of their success is a commitment to partnership. Unlike off-the-shelf solutions, Steel Star often works closely with clients from the conceptual stage. Their engineering team analyzes the desired metal profile, recommends the optimal mechanical configuration, and designs a complete line that may include decoilers, pre-punching or notching units, the main roll former, cut-off systems, and run-out tables. This turnkey approach ensures seamless integration and peak performance in the client’s facility.

The impact of this focused dedication is visible in the enduring performance of their machines. A 15-year-old Steel Star roll former in a manufacturing plant is often not just operational but remains a productive asset, a testament to superior build quality and timeless design principles. This longevity provides clients with an exceptional return on investment and minimizes total cost of ownership.

Looking forward, the expertise gained over 15 years positions Steel Star Machine at the forefront of emerging trends. The integration of IoT connectivity for data analytics and predictive maintenance is becoming standard, pushing roll forming further into the smart factory ecosystem. Furthermore, there is a growing focus on designing machines that handle newer, lighter, or stronger materials, including advanced high-strength steels and composites.

In conclusion, the 15-year story of Steel Star Machine in the realm of roll forming is one of steadfast growth and specialized mastery. It demonstrates how deep focus on a critical manufacturing process, combined with a willingness to innovate and a philosophy of client collaboration, builds a lasting legacy. Their machines are not merely tools; they are the durable, intelligent engines that shape the material world around us, quietly driving progress in countless industries, one precise, consistent profile at a time.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)