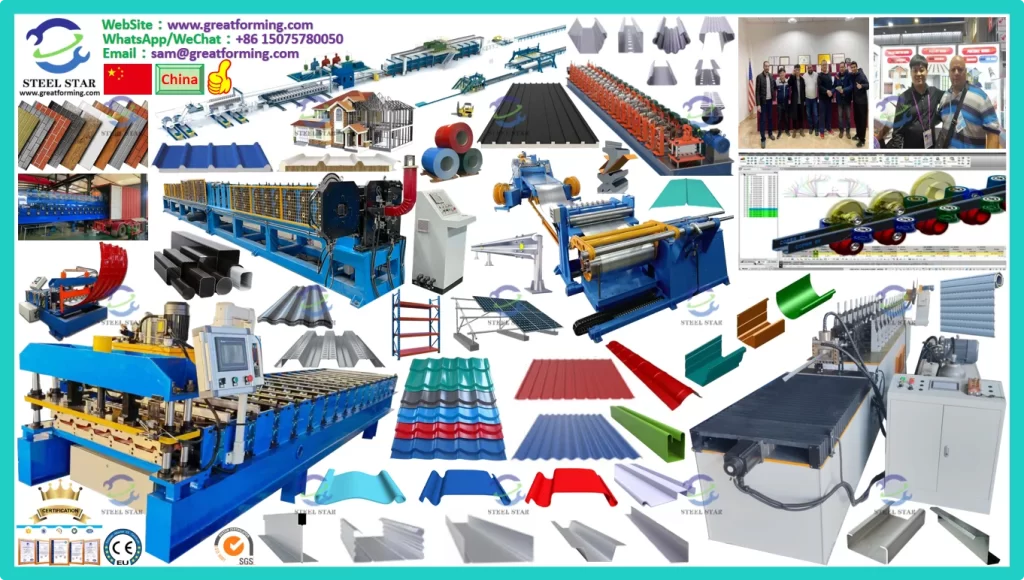

Steel Star Forming Machine: 15 Years of Chinese Manufacturing Excellence

In the global landscape of industrial equipment, few narratives are as compelling as the rise of specialized manufacturers who combine deep technical expertise with relentless innovation. Steel Star Forming Machine, a prominent name hailing from China’s robust manufacturing sector, exemplifies this trajectory. With 15 years of dedicated industry experience, the company has carved a significant niche in the design and production of high-performance roll forming and related metal forming machinery, evolving from a domestic player into a competitive force on the world stage.

The journey of Steel Star is intertwined with China’s own industrial transformation over the past decade and a half. Founded at a time when the market was demanding higher quality and more sophisticated manufacturing solutions, the company focused its mission on precision, durability, and technological integration. Unlike generic equipment providers, Steel Star specialized in the complex process of roll forming—a continuous, cost-effective method for shaping metal coils into consistent, complex cross-sectional profiles used in construction, automotive, appliance, and storage industries.

This 15-year foundation is built upon a core philosophy of engineered robustness. Steel Star machines are renowned for their heavy-duty construction, utilizing high-grade materials and precision machining to ensure stability under continuous high-load operation. This commitment to durability minimizes long-term wear and tear, providing clients with a lower total cost of ownership and exceptional machine longevity, a key factor in their reputation for reliability.

However, endurance alone does not define modern success. Steel Star’s experience has been marked by continuous technological ascent. The company has systematically integrated advanced digital controls into its mechanical prowess. Today, a standard Steel Star roll forming line often features sophisticated PLC systems, servo-electric drives for exceptional accuracy, user-friendly HMIs (Human-Machine Interfaces), and quick-change cartridge systems that drastically reduce downtime during profile changeovers. This blend of sturdy hardware and smart software allows for both high-volume production and the flexibility required for smaller, customized batches.

A significant pillar of their 15-year growth is a client-centric approach to engineering. Steel Star typically engages in collaborative partnerships, working closely with customers to develop turnkey solutions. Their engineering team analyzes specific profile requirements, material properties, and production goals to design, manufacture, and commission complete forming lines. This includes auxiliary equipment like decoilers, pre-punching stations, cutting systems, and run-out tables, ensuring seamless integration and optimal performance in the client’s facility.

As a manufacturer based in China, Steel Star leverages the advantages of a concentrated supply chain and significant manufacturing ecosystem. This allows for competitive pricing without compromising on core quality, making advanced forming technology accessible to a broader range of businesses worldwide. Furthermore, the company has invested in building international service and support networks, understanding that global customers require prompt technical assistance and reliable spare parts supply.

Looking to the future, the 15 years of experience serve as a crucial platform for next-generation innovation. Steel Star is well-positioned to lead in areas like the integration of Industry 4.0 principles, incorporating IoT sensors for predictive maintenance and data analytics, and developing machines capable of handling newer, sustainable materials.

In conclusion, Steel Star Forming Machine represents a success story of focused industrial evolution. Their 15-year milestone is not merely a measure of time, but a testament to accumulated expertise, adaptive innovation, and a steadfast commitment to quality. From its foundation in China’s dynamic manufacturing heartland, the company has proven that specialized mastery and client partnership can build machinery—and a reputation—that stands the test of time, shaping the future of metal fabrication one precise profile at a time.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)