Steel Pipe Making Machine: Technology, Types, and Industrial Applications

This article provides a comprehensive overview of steel pipe making machines—industrial equipment designed to transform raw steel materials into pipes and tubes of various diameters, thicknesses, and specifications. It examines the primary manufacturing processes (seamless and welded), explores machine configurations and technological advancements, and discusses their critical role in global infrastructure, energy, and construction sectors.

1. Introduction

Steel pipes are fundamental components in modern infrastructure, utilized in applications ranging from fluid transportation and structural supports to mechanical systems and architectural designs. Steel pipe making machines enable the high-volume, precise, and efficient production of these essential components. The evolution from manual pipe forming to fully automated, computer-controlled production lines has revolutionized pipe manufacturing in terms of quality, scalability, and material efficiency.

2. Core Manufacturing Processes

Steel pipe production is broadly categorized into two methods, each requiring specialized machinery.

2.1 Seamless Pipe Production

Seamless pipes are manufactured without welding seams, offering superior strength and uniformity, especially for high-pressure applications.

- Mandrel Mill Process: A solid steel billet is heated and pierced by a mandrel to form a hollow shell, which is then elongated and rolled to the desired dimensions.

- Plug Mill Process: Similar to the mandrel mill but uses a different rolling mechanism for wall thickness control.

- Machinery Involved: Rotary hearth furnaces, piercing mills, elongators, sizing mills, and cooling beds.

2.2 Welded Pipe Production

Welded pipes are formed from steel strips or plates (skelp) bent into a cylindrical shape with the edges welded together. This method is highly efficient for large-diameter and high-volume production.

- Electric Resistance Welding (ERW): Edges are heated by electrical resistance and forged together under pressure without filler metal.

- Submerged Arc Welding (SAW): Used for large-diameter pipes; welding is performed under a layer of flux, allowing for thick walls and high deposition rates.

- Longitudinal vs. Spiral Welding: Pipes can be welded along a straight seam (longitudinal) or in a helical pattern (spiral), with the latter offering advantages in diameter flexibility and strength distribution.

3. Key Components of a Pipe Making Machine Line

A complete production line integrates multiple stations:

- Uncoiling & Leveling: Prepares the steel coil by removing curvature and ensuring flatness.

- Edge Trimming: Trims strip edges to ensure clean, parallel sides for proper welding alignment.

- Forming Section: A series of progressively arranged roller dies that gradually bend the flat strip into a circular profile. Common forming methods include the cage forming and edge bending techniques.

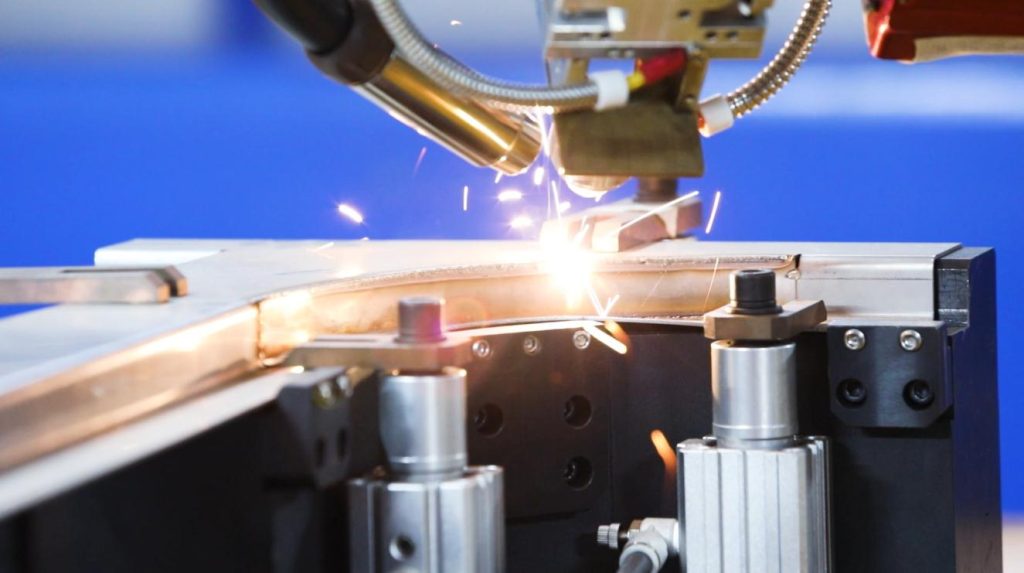

- Welding Unit: The core of a welded pipe line. ERW lines use high-frequency induction or contact welding; SAW lines use automatic welding heads.

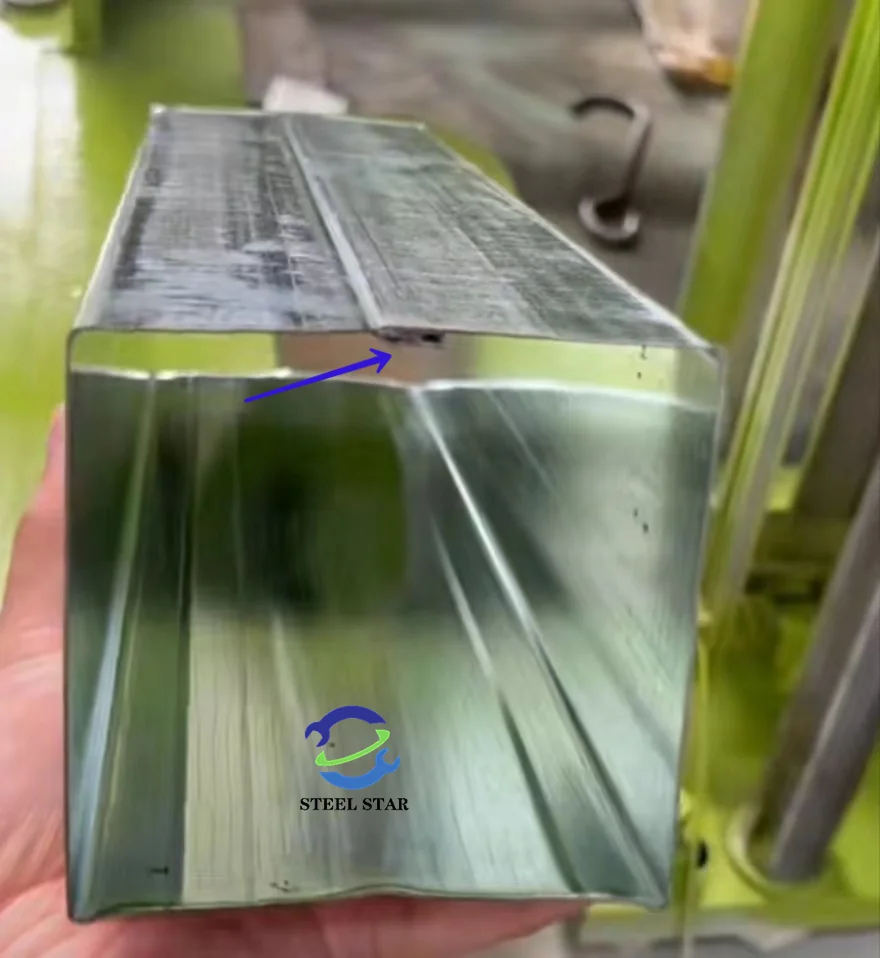

- Sizing Section: A set of calibrated rolls that cold-work the welded pipe to achieve exact outer diameter and roundness.

- Cutting Unit: Flying saws or torches that cut the continuous pipe to specified lengths.

- End Finishing & Testing: Machines for bevelling ends, and systems for non-destructive testing (hydrostatic, ultrasonic, X-ray) to ensure quality.

4. Technological Advancements

Modern pipe making machines incorporate advanced technologies to enhance precision, efficiency, and adaptability:

- Digital Process Control: PLC and HMI systems for centralized control of speed, temperature, and forming pressure.

- Automated Quality Assurance: In-line laser gauges, ultrasonic flaw detectors, and vision systems for real-time defect detection.

- High-Frequency & Laser Welding: Improved weld quality, speed, and material compatibility.

- Flexible Manufacturing Systems: Quick-change tooling and programmable settings allow one line to produce multiple pipe diameters and specifications with minimal downtime.

- Energy Efficiency: Use of regenerative drives, efficient induction heaters, and heat recovery systems.

5. Industrial Applications and Product Range

Pipe making machines are configured to produce a vast array of products:

- Standard Pipes: For plumbing, fencing, and low-pressure applications.

- Line Pipes: API-grade pipes for oil and gas transmission.

- Structural Tubes: Square, rectangular, or custom profiles for construction.

- Mechanical & Precision Tubes: For automotive, bearing, and hydraulic systems.

- Diameter Range: From small-diameter tubing (~10mm) to large-diameter pipes over 2 meters.

- Material Compatibility: Carbon steel, stainless steel, alloy steels, and some non-ferrous metals.

6. Environmental and Safety Considerations

Contemporary designs prioritize sustainability and operator safety:

- Closed-Loop Cooling Systems: Reduce water consumption.

- Fume Extraction and Filtration: Capture welding smoke and particulate matter.

- Noise Abatement: Enclosures and dampening for high-noise components.

- Safety Interlocks and Guarding: Comprehensive machine guarding and emergency stop systems.

7. Future Trends

The future of steel pipe machinery is shaped by several key trends:

- Integration with Industry 4.0: Full digital integration for predictive maintenance, production optimization, and supply chain connectivity.

- Additive Manufacturing Hybridization: Combining traditional forming with 3D printing for complex fittings or alloy deposition.

- Lightweighting and Material Science: Adapting to produce pipes from advanced high-strength steels and composites.

- Sustainability-Driven Design: Machines optimized for recycling scrap and producing pipes for renewable energy sectors (hydrogen, carbon capture, geothermal).

Steel pipe making machines represent a sophisticated fusion of mechanical engineering, metallurgy, and automation technology. They are the backbone of a critical industry that supplies essential components for global infrastructure, energy security, and industrial development. From the robust mills producing seamless pipes for deep-sea drilling to the high-speed ERW lines manufacturing conduit for urban construction, these machines continue to evolve. Driven by digitalization and the demand for smarter, greener infrastructure, the next generation of pipe making technology will focus on unprecedented flexibility, material efficiency, and integration into the digital manufacturing ecosystem, ensuring steel pipes remain indispensable in an advancing world.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)