The Engine of Modern Construction: An In-Depth Look at the Floor Deck Machine

The contemporary skyline, defined by soaring steel-framed structures and expansive commercial spaces, relies on a hidden yet fundamental component: the composite floor deck. This corrugated steel sheet serves as permanent formwork, structural reinforcement, and a working platform during construction. At the heart of its mass production lies a sophisticated piece of industrial equipment—the Floor Deck Machine. This machine is a critical enabler of speed, efficiency, and innovation in the building industry.

Core Function and Principle

A floor deck machine is a heavy-duty, continuous cold roll forming system. Its primary function is to transform raw, flat steel coil into precise, high-strength corrugated profiles in a single, uninterrupted process. The transformation occurs not through cutting or welding, but through progressive, plastic deformation.

The operational principle follows a precise sequence:

- Material Loading: A massive coil of mild steel, typically galvanized or painted, is mounted onto a powered decoiler.

- Feeding and Leveling: The steel strip is fed into a precision leveling unit. This crucial step eliminates any coil curvature or “memory,” ensuring a perfectly flat sheet enters the forming process, which is vital for profile accuracy.

- Pre-Punching/Embossing (Optional): For enhanced composite action with concrete, many machines integrate a servo-electric punching station. This unit can perforate the steel web with precise indentations (“embossments”) or create custom holes for mechanical, electrical, and plumbing (MEP) services on the fly.

- The Roll Forming Mill: The heart of the machine. The steel strip passes through a series of paired roll stands (often 18 to 30 stations). Each station contains a set of hardened steel rollers, machined to exacting tolerances. Each successive stand incrementally bends the steel by a few degrees, gradually forming the final trapezoidal, re-entrant, or dovetail rib profile without removing any material. This cold-forming process work-hardens the steel, increasing its yield strength.

- Cut-off and Control: At the end of the line, a high-precision, computer-controlled flying cut system—hydraulic or servo-driven—synchronizes with the moving profile to shear it to the exact required length without stopping production. The entire process is governed by a Programmable Logic Controller (PLC), which manages speed, length, and punching patterns.

Key Components and Technological Sophistication

- Heavy-Duty Decoiler & Entry Guide: Designed to handle coils weighing several tons, providing consistent, tension-controlled feed.

- Precision Leveling System: A multi-roll leveler is essential for producing flat, defect-free decking.

- Servo Punching Unit: A hallmark of advanced machines, allowing for programmable, high-speed punching of embossments and service holes, customizable per project specification.

- Forming Rollers & Shafts: Manufactured from high-grade alloy steel (e.g., Cr12) and often coated or hardened, these are the custom-made “tooling” that defines the profile geometry. Quick-change designs allow for flexible production.

- PLC with HMI (Human-Machine Interface): The operational nerve center. It stores recipes for different profiles, controls all synchronized motions, and provides diagnostic data for operators.

The Transformative Advantages

The roll forming process offers decisive benefits over alternative methods:

- Unmatched Speed and Volume: Capable of producing 30-80 meters of finished deck per minute, it meets the massive demand of large-scale projects.

- Superior Consistency and Dimensional Accuracy: Every panel is identical, ensuring predictable structural performance and seamless on-site installation.

- Material Efficiency and Strength: The process generates virtually no scrap (aside from the initial coil tail). Cold-working increases the strength of the final product.

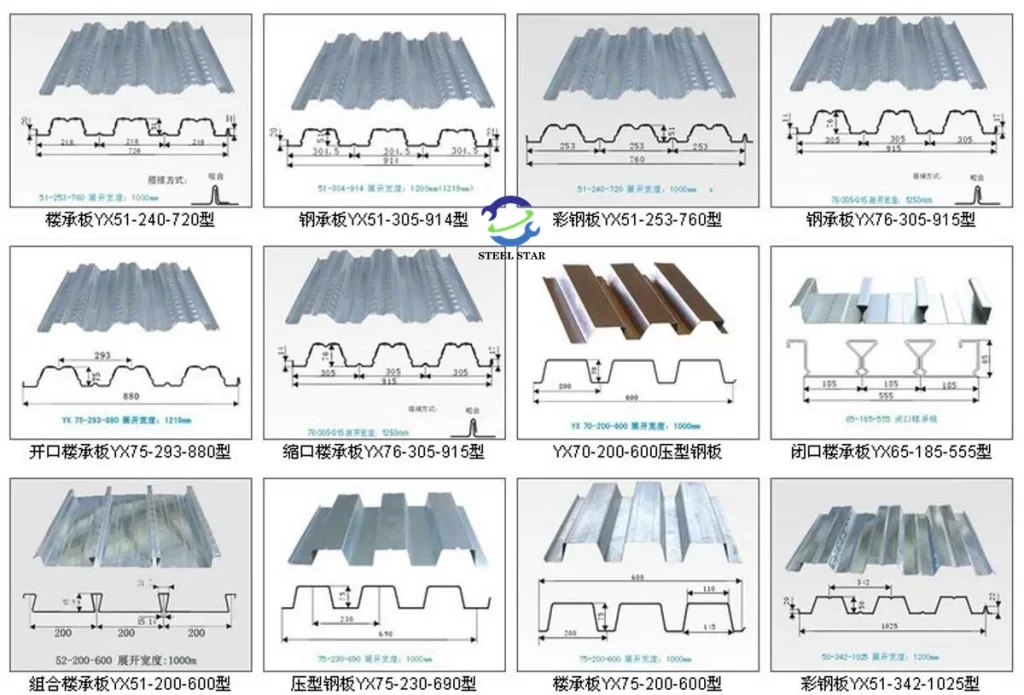

- Design Flexibility: By changing the roll sets, a single machine can produce various profile depths (e.g., from 38mm to 80mm), widths, and styles to meet different load-bearing and span requirements.

Applications and Profile Diversity

These machines produce the essential decking for:

- Composite Floor Systems: The most common application, where the deck acts as tensile reinforcement for a concrete slab.

- Permanent Formwork: For concrete slabs in parking structures and basements.

- Standing Seam Roof Deck: A different profile used for roofing applications.

- Cellular Decking: More advanced machines can integrate services into the deck profile itself.

Evolution and Future Trends

The technology continues to advance, focusing on:

- Increased Automation and IoT: Integration with factory management systems, predictive maintenance sensors on critical bearings, and production data analytics.

- Higher Strength Steels: Machines are being engineered to form newer, high-yield-strength steels (e.g., S550) for lighter, stronger decks.

- “Smart” Production Lines: Linking the deck line directly to CAD/BIM models, where panel lengths and hole patterns are automatically downloaded, minimizing human error and customization time.

The floor deck machine is a cornerstone of modern industrialized construction. It is a symphony of mechanical engineering, metallurgy, and digital control, transforming a simple coil of steel into a high-performance building product. By enabling the rapid, precise, and cost-effective manufacture of composite metal decking, this technology directly contributes to shorter project timelines, reduced on-site labor, and the realization of ambitious architectural designs. It is, in every sense, the silent engine building the floors beneath our feet.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)