The Roofing Sheet Roll Forming Machine: Precision in Profile Production

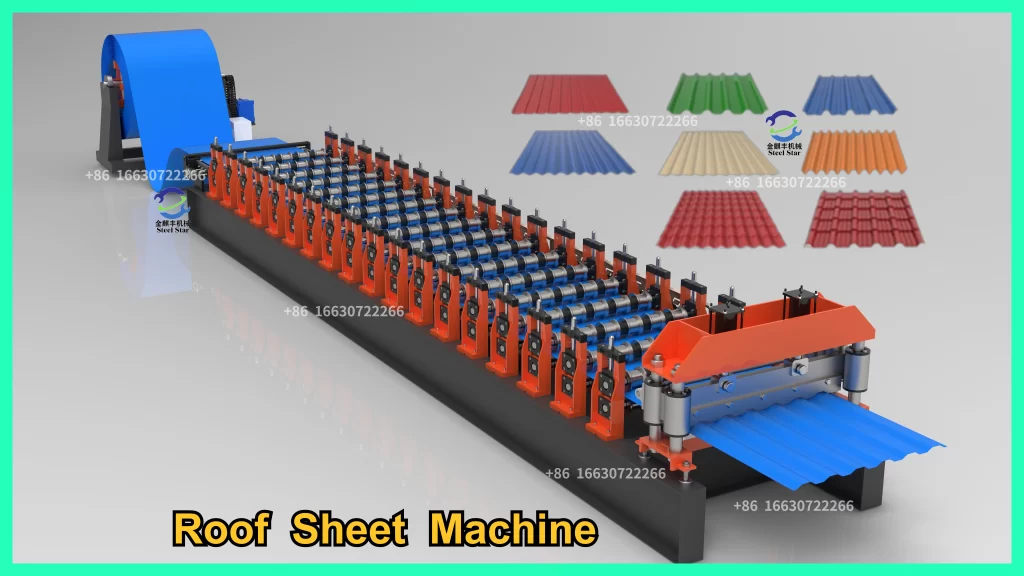

In the construction industry, efficiency, durability, and cost-effectiveness are paramount. For the production of the essential building envelope component—metal roofing and cladding sheets—the Roofing Sheet Roll Forming Machine stands as a cornerstone of modern manufacturing technology. This specialized equipment transforms continuous coils of galvanized steel, aluminum, or pre-painted metal into precise, high-strength profiles with remarkable speed and consistency.

Core Function and Working Principle

At its heart, a roll forming machine is a linear, continuous bending operation. The process begins with a decoiler holding a large metal coil. The strip is fed into a series of paired roller dies (stages), mounted on consecutive stations. Each set of rollers progressively bends the metal incrementally until the desired cross-sectional profile is achieved. Unlike punching or stamping, this gradual cold-forming process minimizes stress and strain on the material, preserving its protective coatings and structural integrity. After shaping, the continuous panel is cut to predetermined lengths by a synchronized flying cut-off system, without halting the line, ensuring seamless production.

Key Components and Features:

- Decoiler & Entry Guide: Holds and feeds the metal coil into the machine smoothly.

- Roll Forming Station: The main frame housing the sequenced roller dies, typically made from high-grade alloy steel for longevity.

- PLC Control System: The “brain” of the machine. It allows for precise adjustment of speed, length, and quantity, and stores recipes for different profiles.

- Flying Cut Mechanism: Accurately shears the formed sheet to length using a hydraulic or servo-driven system.

- Output Conveyor & Stacker: Gently transports finished sheets and automates stacking for packaging.

Advantages Over Traditional Methods:

- High Speed & Output: Capable of producing 30-100 meters per minute, far outpacing manual or single-piece fabrication.

- Consistency & Quality: Every sheet is identical, ensuring uniform appearance, fit, and performance on the roof.

- Material Efficiency: Minimal waste is generated compared to cutting individual sheets from a plate.

- Profile Flexibility: By changing the roller dies, one machine can produce various profiles (e.g., corrugated, trapezoidal, tile-effect) from the same base material.

- Labor Savings: The process is largely automated, requiring minimal operator intervention.

Evolution and Technological Integration

Modern roofing sheet machines have evolved beyond basic forming. Today’s advanced lines often integrate:

- Pre-punching/Perforating Units: For creating vented or custom aesthetic sheets in-line.

- Embossing Rolls: To add wood-grain or textured patterns.

- Automatic Measurement & Feedback: Ensuring dimensional accuracy in real-time.

- Servo-Driven Systems: Providing superior cut accuracy, flexibility, and energy efficiency.

Economic and Industry Impact

The widespread adoption of roll forming technology has directly enabled the growth of metal roofing globally. It allows manufacturers to respond quickly to project demands, produce cost-effective yet high-quality materials, and contribute to sustainable construction with long-lasting, recyclable roofing solutions. From large-scale industrial sheds to residential buildings, the profiles produced by these machines offer superior weather resistance, longevity, and aesthetic appeal.

The Roofing Sheet Roll Forming Machine is a paradigm of manufacturing elegance—turning a simple coil of metal into a vital architectural element through a seamless, precision-engineered process. It is a critical investment for metal fabricators, driving productivity, innovation, and quality in the construction supply chain. As building technologies advance, so too will these machines, incorporating smarter automation and adaptability to shape the roofs over our heads for decades to come.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)