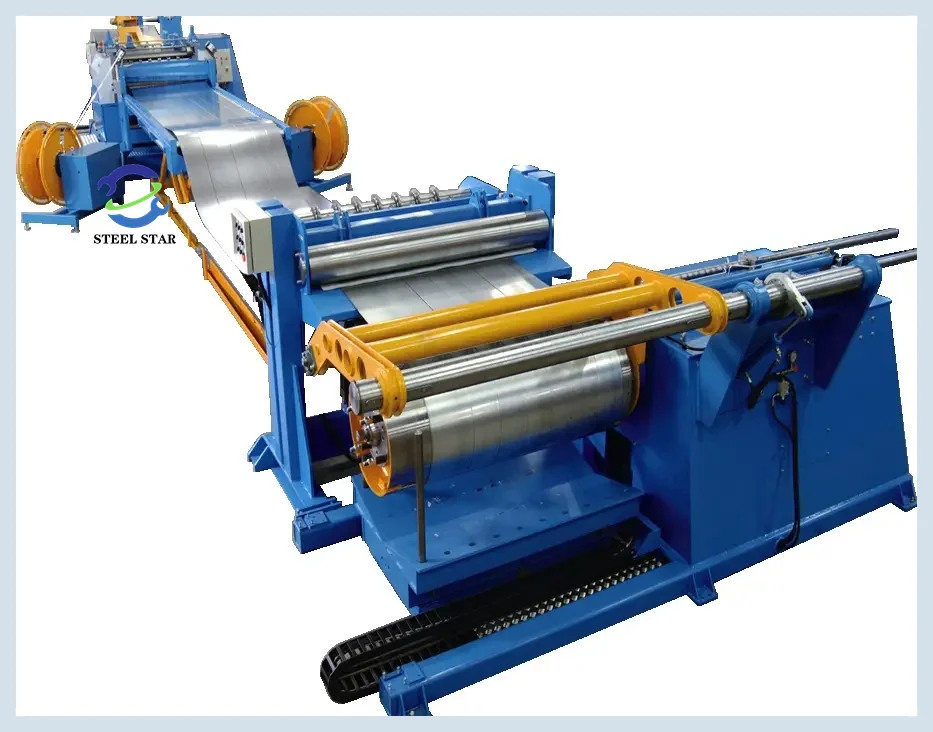

The steel slitter machine is a critical piece of industrial equipment at the heart of metal service centers and manufacturing plants worldwide. Designed to accurately and efficiently cut wide master coils of steel into multiple narrower strips, this machinery serves as a fundamental first step in preparing material for a vast range of downstream applications, from automotive stamping and appliance manufacturing to construction and roll forming.

Core Function and Process

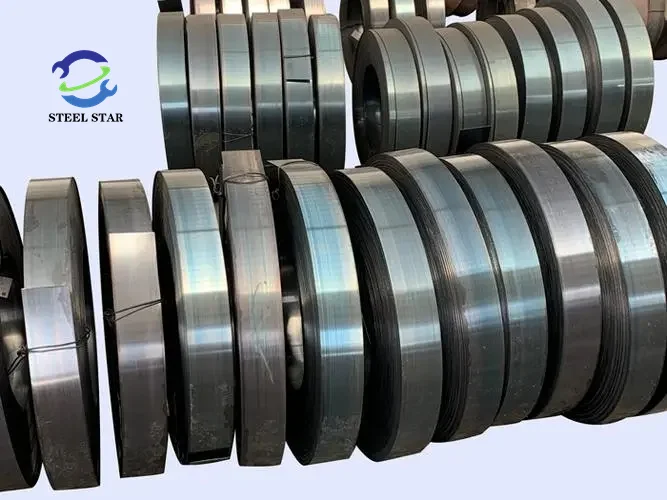

The primary function of a steel slitter is to perform a longitudinal cutting operation. It transforms a single wide coil of cold-rolled, galvanized, or stainless steel—often ranging from 600mm to over 2000mm in width—into several narrower strips of predetermined widths, typically between 20mm and 600mm. This process, known as coil slitting, maintains the original coil’s thickness and metallurgical properties while creating multiple, ready-to-use “daughter” coils from one “mother” coil.

Key Components of a Modern Slitting Line

A complete, high-performance slitting line integrates several synchronized subsystems:

- Pay-Off Reel (Decoiler): A heavy-duty unit equipped with a hydraulic expansion mandrel to securely hold and feed the master coil into the line. Modern systems often feature automatic coil loading cars for efficiency and safety.

- Entry Pinch Roll & Leveler: Guides the leading edge and feeds the material. An integral multi-roll leveler removes coil set (longitudinal curvature) and crossbow, ensuring the steel is perfectly flat before it enters the slitter head—a critical step for achieving precise cut widths.

- The Slitter Head: The machine’s core. It consists of:

- Upper and Lower Arbors: Precision-ground, hardened steel shafts that hold the cutting tools.

- Slitter Knives (Circular Blades): Mounted in pairs (top and bottom). The sharp, hardened top knives are driven, while the bottom knives act as idlers. The spacing between the knives determines the final strip width.

- Spacers and Shims: Used to set the exact distance between knives on the arbors. Accuracy here is paramount for maintaining tight width tolerances.

- Scrap Winders: Separate and recoil the thin edge trim created during slitting, preparing this scrap for efficient recycling.

- Strip Separator (Drag System): Prevents the newly slit strips from overlapping or tangling as they exit the slitter head, typically using a series of curved plates or rollers.

- Tension Stand (Bridle): Creates and maintains critical back tension on the strip during the slitting and recoiling process. Consistent tension is essential for producing tight, stable daughter coils.

- Re-coilers: One or multiple units that wind the finished narrow strips into individual coils. Advanced lines use dual dual-shaft re-coilers for non-stop production: one set winds while the other is unloaded.

- Programmable Logic Controller (PLC): The central nervous system. It integrates and controls all drives, hydraulics, and pneumatics, managing line speed, tension, and often providing a coil data management system for tracking.

Slitting Methods and Technical Considerations

The choice of slitting method depends on material grade, thickness, and desired edge quality:

- Pull-Through Slitting: A simpler configuration where the re-coiler pulls the material through the slitter. Often used for thicker or higher-strength steels.

- Loop Slitting: Material forms a controlled loop between the slitter and the re-coiler. This allows for superior tension control and is preferred for thin-gauge, coated, or high-precision applications.

- Cutting Styles: Shear cutting (using opposed knives) is standard for most steel. Score cutting (using a sharp blade against a hardened roll) may be used for very thin materials to minimize burr.

Advantages and Economic Impact

- Massive Throughput and Yield Optimization: Processes entire master coils in a single, continuous operation, maximizing material utilization and minimizing scrap.

- Precision and Consistency: Delivers narrow strips with extremely tight width tolerances (often ±0.1 mm) and clean, controlled edges, which is crucial for high-speed automated downstream processes like progressive die stamping.

- Flexibility and Quick Changeover: With quick-change tooling systems, a line can be set up for different strip widths and material grades in minutes, supporting just-in-time (JIT) manufacturing and a wide product mix.

- Labor Efficiency: High levels of automation significantly reduce manual handling and operator intervention, lowering production costs and improving safety.

The modern steel slitter machine is an exemplar of precision industrial engineering. It is an indispensable link in the metal supply chain, transforming bulk raw material into tailored feedstock for countless manufacturing sectors. By combining robust mechanical design with sophisticated digital control, it ensures that the foundational material for modern industry—steel strip—is delivered with the exacting quality, consistency, and efficiency required by global manufacturers. Its role in enabling cost-effective, high-volume production makes it a silent yet vital workhorse of industrial infrastructure.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)