The Ridge Cap Machine: Precision at the Peak

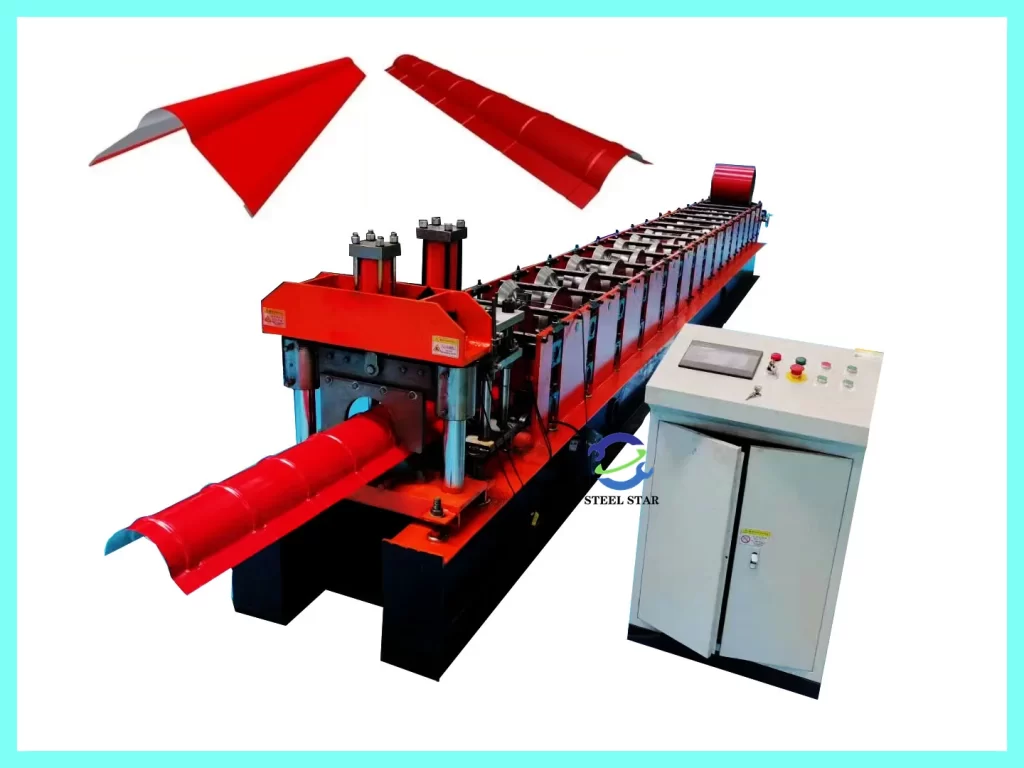

In the world of metal roofing and cladding, the ridge cap—the final, crucial piece that seals the intersection of two sloping roof planes—is paramount for weatherproofing, durability, and aesthetic finish. The Ridge Cap Machine is the specialized roll-forming equipment designed to manufacture these essential components with speed, consistency, and precision, directly on-site or in a factory setting.

Core Function and Importance

A ridge cap, also known as a ridge roll or ridge flashing, is more than just a cover. It must provide a continuous, water-shedding seal over the peak of a roof while allowing for ventilation, accommodating thermal expansion, and matching the profile and coating of the main roof sheets. Manually bending or forming these long, complex sections is time-consuming and prone to inconsistency. The Ridge Cap Machine automates this process, producing perfectly formed, uniform lengths that ensure a professional, leak-resistant roof termination.

Machine Types and Operation

There are two primary configurations:

- Stand-Alone / Portable Roll Formers: These are compact, often trailer-mounted machines used directly on construction sites. They take coiled strip metal (pre-painted steel, aluminum, or zinc) and form it into a continuous ridge cap profile in one pass. Their key advantage is the elimination of length limitations and transport damage, as caps can be formed to the exact required length, even for very long roof runs.

- In-Line Auxiliary Units: In a factory setting, a ridge cap forming station can be integrated as a final module on a main roof panel roll-forming line. After the primary panel is formed and cut, the side trim (or a separate coil) can be fed into an integrated ridge cap unit, maximizing material efficiency and ensuring perfect color/profile matching.

The basic operational principle is roll forming. A flat metal strip is guided through a series of progressively shaped roller dies. Each set of rollers makes a slight bend until the final, complex cross-section—which may include integral legs, sealant channels, venting baffles, and decorative rolls—is achieved. A flying cut-off then cuts the continuous formed product to the specified length.

Key Technical Features and Capabilities

- Quick-Change Tooling: Modern machines allow for relatively fast changes between different ridge cap profiles (e.g., standard round, high-profile, ventilated, hip ridge) by switching out the set of forming rolls.

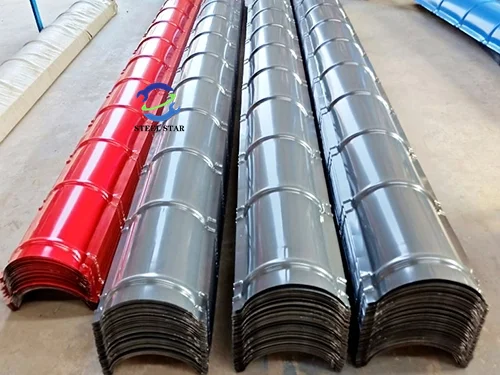

- Flexible Material Handling: They can process various metallic coatings (galvalume, galvanized) and paint systems, as well as different metal types and thicknesses (typically 0.4mm to 1.0mm).

- Precision Cutting Systems: Servo-driven flying cut-off saws or shears ensure clean, square, and burr-free cuts at exact lengths without stopping the forming process.

- Integration with Ancillary Processes: Some machines can incorporate in-line operations such as adhesive tape application for sealants, pre-punching for fastener locations, or even embossing for enhanced stiffness.

Benefits and Impact

- Quality and Consistency: Automated production guarantees every meter of ridge cap has identical geometry, which is critical for proper fit and a uniform appearance.

- Speed and Efficiency: On-site formation dramatically reduces installation time and labor costs, accelerating project completion.

- Material Optimization: Reduced waste from off-cuts and elimination of damage during transport from a factory.

- Versatility: Ability to produce custom lengths and special profiles for architectural projects or complex roof designs.

The Ridge Cap Machine represents a critical niche in metal construction technology. By bringing precision manufacturing to the jobsite or streamlining factory production, it solves a key challenge in roofing systems: creating a perfect, durable seal at the most vulnerable point. It is a testament to the industry’s move towards integrated, automated solutions that enhance performance, reduce total cost, and ensure the long-term integrity of the building envelope. From large industrial warehouses to custom architectural homes, this machine ensures the roof is crowned with perfection.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)