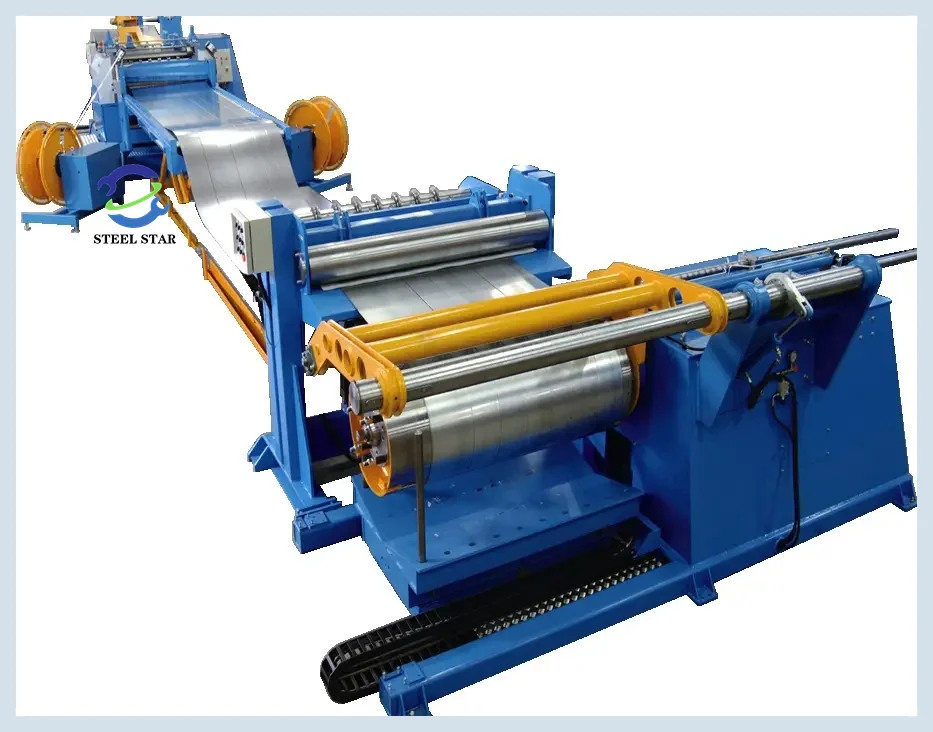

Steel Coil Slitting Machine Price: A Comprehensive Market Guide

Purchasing a steel coil slitting machine is a significant capital investment for any metal service center, processor, or fabricator. The price of this essential industrial equipment is not a single figure but a broad range, typically spanning from $50,000 to over $1,000,000 USD. This vast disparity is dictated by a machine’s technical specifications, capabilities, and the manufacturer’s origin. Understanding the cost drivers is crucial for making an informed investment.

The Core Price Determinants: A Breakdown

- Machine Type & Width Capacity:

- Narrow Strip Slitters (Up to 600mm / 24″): These are the most affordable, suitable for light-gauge materials (like for electronics or appliances). Prices generally range from $50,000 – $250,000.

- Medium-Width Slitters (600mm – 1500mm / 24″ – 60″): This is the most common category for general metal processing. Prices vary widely based on other features, starting around $150,000 and reaching $600,000.

- Heavy-Duty Wide Slitters (1500mm+ / 60″+): Designed for processing high-strength, thick coils at high speeds, these robust machines are premium investments, often costing $500,000 to $1.5 million or more.

- Material & Gauge Capability: The ability to slit high-tensile-strength steel (AHSS) or thicker gauges (over 6mm) requires a massively built frame, more powerful drive motors, and heavier arbors. This directly and significantly increases cost.

- Key Components & Technology Level:

- Drive System: Machines with individual, servo-driven loop control for superior tension management are far more expensive than simpler, single-motor designs.

- Tooling (Arbors & Slitter Heads): Quick-change, hydraulic tooling systems add considerable cost but drastically reduce changeover time. The quality of the slitter knives themselves is a separate, major expense.

- Automation: Features like automatic edge guiding, computerized slit width setup, robotic strip handling, and integrated packaging lines are major price adders but boost productivity.

- Line Speed: A machine rated for 100 m/min is less costly to build than one designed for 800 m/min, which demands higher-grade components throughout.

- Manufacturer Origin (A Major Influencer):

- Chinese Manufacturers: Offer the widest price range. While entry-level machines can be very cost-competitive (starting as low as $50,000), leading Chinese brands now produce high-performance slitters with advanced features at a lower price point than Western counterparts, though potential buyers must diligently vet quality, service, and parts availability.

Total Cost of Ownership (TCO): Beyond the Purchase Price

Smart buyers evaluate the Total Cost of Ownership:

- Installation & Commissioning: Can be 5-15% of the machine cost.

- Tooling & Spare Parts: A critical ongoing cost. High-quality slitter knives and spacers are essential for cut quality.

- Energy Consumption: More powerful, faster machines have higher operating costs.

- Maintenance & Downtime: A reliable machine from a reputable supplier with local service support minimizes costly production interruptions.

- Waste & Yield: A precision slitter with excellent tension control minimizes edge burr and dimensional error, directly improving material yield and profitability.

Current Market Trends Influencing Price

- Automation & Industry 4.0: Integration of IoT sensors for predictive maintenance and AI for optimizing slit patterns is becoming a premium feature.

- Demand for Flexibility: Machines that can handle a wider variety of materials (e.g., switching between aluminum, mild steel, and high-strength steel) command higher prices.

- Supply Chain & Raw Material Costs: Global steel prices and component shortages continue to apply upward pressure on machine costs.

Procurement Advice

- Define Your Exact Needs: Analyze your primary material (grade, thickness, width), required output, and target tolerances. Avoid over-specifying.

- Request Detailed Quotations: Ensure quotes include delivery, installation, training, warranty, and a spare parts list.

- Prioritize Lifecycle Value: The cheapest capital cost often leads to the highest TCO. Evaluate the manufacturer’s reputation, service network, and expected machine lifespan.

- Consider Quality Used/Refurbished: A well-maintained used machine from a known brand can offer exceptional value, often at 40-70% of the new price.

The price of a steel coil slitting machine is a direct reflection of its performance, durability, and technological sophistication. While initial investment is a primary concern, the true measure of value lies in its precision, reliability, and contribution to your operational efficiency over 15-20 years. A thorough analysis of both technical specifications and the manufacturer’s total support package is essential to secure an asset that enhances competitiveness and delivers a strong return on investment in the demanding metal processing industry.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)