The Double Layer Roofing Sheet Roll Forming Machine: Engineering Superior Weatherproofing

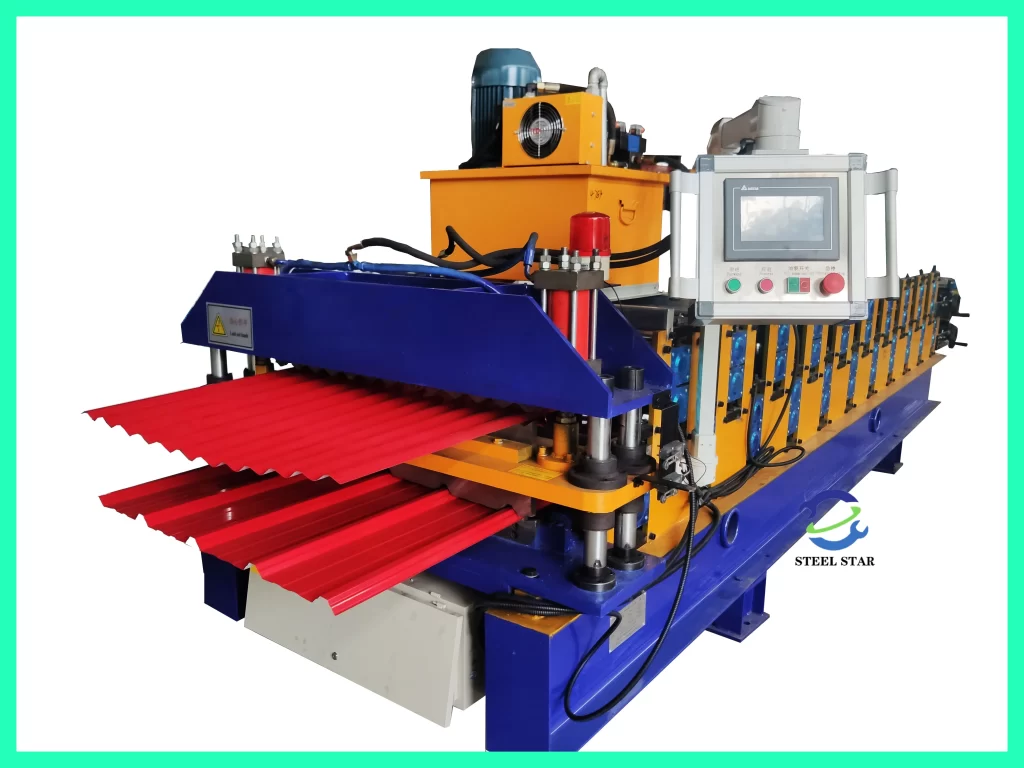

The Double Layer Roofing Sheet Roll Forming Machine represents a significant advancement in building envelope technology, specializing in the production of composite roofing panels that offer unmatched structural integrity, thermal efficiency, and weather resistance. Unlike standard single-skin profiled sheets, this machine fabricates a panel consisting of two metal skins with a continuous, factory-integrated core, creating a complete roofing system directly off the production line.

Core Function and Product Advantage

This machine manufactures standing seam or trapezoidal double-layer roof panels, also known as composite or insulated panels. Its core function is to simultaneously form two separate metal coils—typically pre-painted galvanized steel or aluminum—into precise profiles while continuously injecting and foaming a polyurethane (PUR) or polyisocyanurate (PIR) insulating core between them in a single, synchronized process.

The final product is a lightweight, high-strength sandwich panel that provides:

- Superior Thermal Insulation: The rigid foam core offers a very low U-value, drastically reducing energy costs for heating and cooling.

- Exceptional Sealing: The continuous factory-applied core eliminates interstitial condensation and creates a seamless barrier against air and water infiltration.

- Structural Strength: The composite action of the two metal skins bonded to the core creates a panel with high load-bearing capacity relative to its weight.

- Quick Installation: Large panel lengths and integrated joining systems enable rapid roof deployment.

Machine Configuration and Process Flow

The machine is a complex, continuous production line integrating mechanical forming with chemical reaction processes.

- Uncoiling & Pre-Heating: Two decoilers feed the top and bottom metal coils into the line. The coils often pass through a pre-heating station to optimize temperature for foam adhesion and panel flatness.

- Synchronized Roll Forming: The top and bottom coils enter two independent yet synchronized roll forming sections. Each section uses a series of precision roller dies to progressively shape the metal into the desired profiles (e.g., a standing seam for the top, a flat or micro-rib sheet for the bottom).

- Core Injection & Foaming: This is the technological heart of the machine. As the two formed sheets converge, a high-pressure mixing head injects liquid polyurethane chemicals (isocyanate and polyol) into the cavity between them. The chemicals react and expand rapidly, filling the entire space and bonding chemically to the inner surfaces of both metal skins. The panel moves through a controlled-temperature curing tunnel to ensure complete and uniform foam polymerization.

- Precision Sizing & Cooling: After foaming, the panel passes through a calibrated sizing/cooling section. This unit ensures final panel thickness, width, and flatness while cooling the core to stabilize its structure.

- Cutting & Stacking: A computer-controlled flying saw cuts the continuous panel into specified lengths. Finished panels are then automatically stacked and packaged for shipment.

Key Technical Features and Considerations

- Precision Synchronization: Absolute speed synchronization between the two forming lines and the foam injection system is critical to prevent panel deformation or core defects.

- Foam Dispensing System: Requires precise temperature, pressure, and ratio control of the chemical components. Advanced systems are self-cleaning and recipe-controlled for different foam densities.

- Curing Tunnel: Typically a multi-zone, heated chamber that ensures optimal foam rise and cure kinetics for consistent core quality across the panel width and length.

- Safety Systems: Comprehensive ventilation, gas monitoring, and fire suppression systems are essential due to the chemical processes involved.

Applications and Importance

Double-layer composite panels produced by this machine are the preferred solution for:

- Industrial & Commercial Buildings: Warehouses, factories, logistics centers, and cold storage facilities where thermal efficiency is paramount.

- Clean Rooms & Pharmaceutical Facilities: Requiring stringent climate control and airtight seals.

- Architectural Projects: Used for facades and roofs where aesthetics, performance, and speed of construction are key drivers.

The Double Layer Roofing Sheet Roll Forming Machine is a pinnacle of integrated manufacturing, merging metallurgy, chemistry, and precision engineering. It transforms raw coils into a high-performance building system in one continuous operation. By delivering superior insulation, durability, and installation speed, the panels it produces address the critical demands of modern sustainable construction, making this machine a vital asset for advanced building material manufacturers aiming for the premium segment of the global construction market.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)