The Metal Roofing Roll Former: Precision at Scale for the Building Envelope

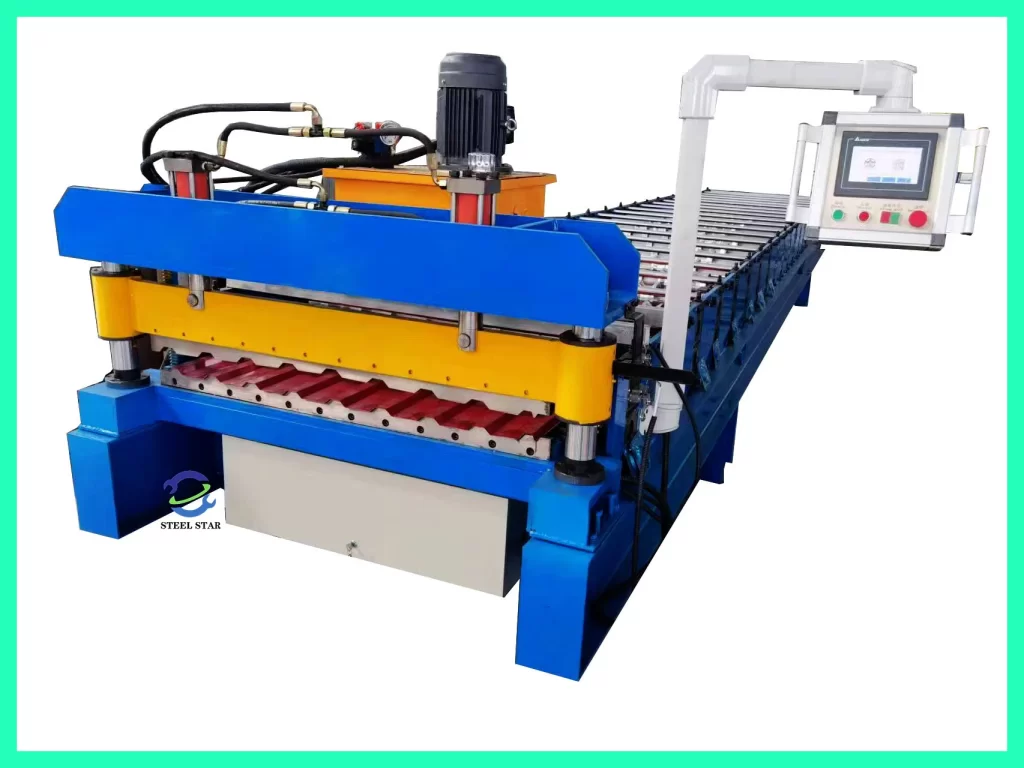

The metal roofing roll former is a specialized and highly efficient machine at the heart of modern construction material manufacturing. It is a continuous cold roll forming system designed to transform flat coils of pre-finished metal into the high-strength, weather-resistant panels that form the roofs and walls of commercial, industrial, and residential buildings worldwide. This machine is the critical link between raw steel or aluminum and the final architectural product.

Core Function and Process

The machine’s operation is based on the principle of progressive roll forming. A coil of metal (typically galvanized steel, Galvalume, or aluminum, often with a pre-painted coating) is fed into the machine, where it undergoes a precise transformation:

- Decoiling & Leveling: The process begins at the decoiler, which holds and feeds the heavy metal coil. The strip first passes through a multi-roll leveling unit to remove any coil curvature or internal stresses, ensuring a perfectly flat starting material.

- Pre-Punching/Notching (Optional): For panels requiring specific fastener patterns, vent holes, or decorative features, a servo-controlled punching station can precisely perforate the flat strip before forming. This is more accurate than post-forming punching.

- The Forming Mill – The Heart of the Machine: The flat strip enters the forming section, a series of paired roller dies mounted on consecutive stands. Each set of rolls makes an incremental bend. As the strip progresses through 10 to 30 stands, these small bends accumulate to create the final, complex profile—whether a classic trapezoidal rib, a standing seam, or a modern tile-effect design—without stretching or damaging the metal’s protective coating.

- Cutting to Length: After the profile is fully formed, the continuous panel passes through a high-speed cutting system. A flying cut-off—a synchronized traveling saw or shear—cuts the moving panel to preset lengths without stopping production, ensuring square, burr-free ends.

- Output & Stacking: Finished panels are conveyed to an automatic stacking station, where they are aligned, counted, and bundled for strapping and shipment.

Key Features and Technological Sophistication

- Profile Flexibility: Quick-change tooling systems allow manufacturers to switch between different panel profiles (e.g., from a 36-inch wide commercial panel to a 16-inch residential panel) with minimal downtime.

- Precision Engineering: The forming rolls are machined from high-grade alloy steel and often chrome-plated for durability and a superior finish. Their design is critical for producing panels with consistent geometry, which is essential for proper interlocking and weathertightness.

- Advanced Control Systems: A central Programmable Logic Controller (PLC) manages the entire line, synchronizing speed, cut length, and auxiliary functions. Modern interfaces allow for storage of hundreds of product recipes.

- High-Speed Operation: Industrial lines can operate at speeds exceeding 200 feet per minute, producing vast square footages per shift.

- Ancillary Integration: Lines can be equipped with in-line embossing for added stiffness, automatic sealant tape application, or even integrated ridge cap and trim formers.

Types of Roofing Panels Produced

The machine is versatile and can be tooled to produce several key panel types:

- Through-Fastened Panels: Such as corrugated or trapezoidal sheets, where screws penetrate the panel face.

- Standing Seam Roof Panels: High-end panels with raised, mechanically seamed joints that conceal fasteners, offering superior weather performance and thermal expansion accommodation.

- Architectural Panels: Including flush-mounted, reveal, or batten-seam systems for sophisticated aesthetic applications.

Importance and Impact

The metal roofing roll former enables the mass production of a superior building material. The resulting panels offer:

- Durability & Longevity: Resistance to fire, wind, corrosion, and impact.

- Speed of Installation: Large, lightweight panels cover area quickly.

- Material Efficiency & Sustainability: High recycled content and full recyclability at end of life.

- Aesthetic Variety: A wide range of profiles, colors, and finishes.

The metal roofing roll former is more than just a fabricator; it is an enabler of modern, resilient, and efficient construction. By delivering consistent, high-quality panels at high volume, it has been instrumental in the widespread adoption of metal roofing. Its continued evolution—towards greater automation, smarter controls, and the ability to form new, advanced alloys—ensures it will remain a cornerstone technology for creating the durable and sustainable building envelopes of the future.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)