Rain Gutter Roll Forming Machine: Precision in Water Management

The rain gutter roll forming machine is a specialized piece of manufacturing equipment designed for the continuous, high-volume production of metal gutter systems. As an essential component of building exteriors, gutters channel rainwater away from structures to protect foundations, siding, and landscaping. This machine transforms flat coils of pre-finished metal into precise, durable, and seamless gutter profiles with remarkable efficiency and consistency.

Core Function and Operational Process

The machine operates on the principle of cold roll forming, a process that incrementally bends a continuous metal strip into a complex cross-section without removing material or using heat. The standard operational sequence is:

- Decoiling & Feeding: A coil of metal—typically painted aluminum, galvanized steel, or copper—is mounted on an uncoiler. The strip is fed into the machine through a guide and leveling system to ensure it enters the forming section perfectly straight and flat.

- Pre-Punching (Optional but Common): For gutters requiring downspout outlets, end caps, or mounting holes, a precision servo-punching unit perforates the flat strip at predetermined intervals before forming. This is far more accurate than post-forming punching.

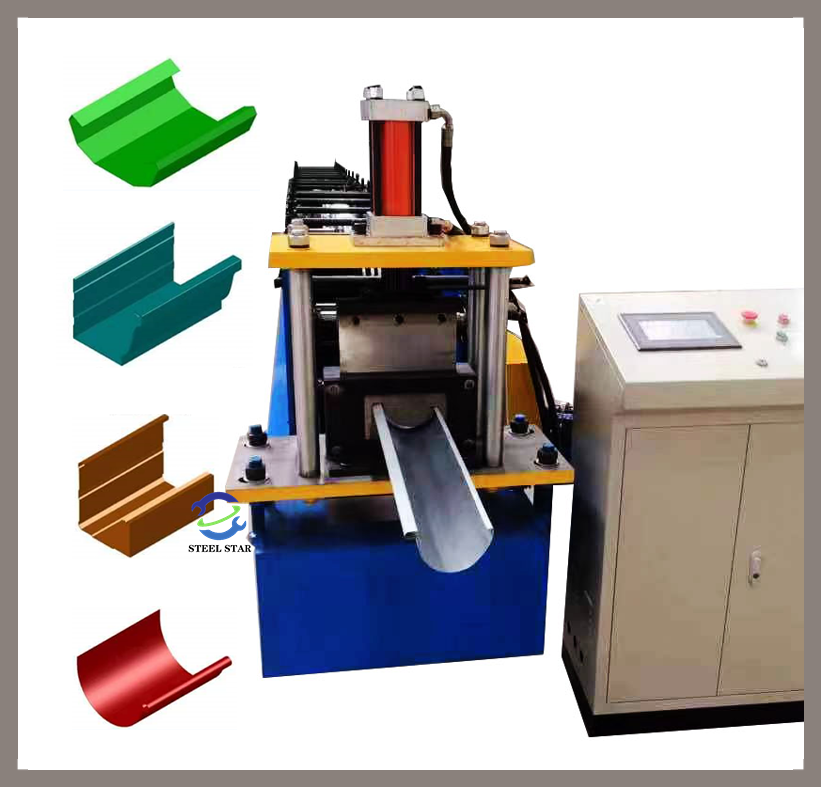

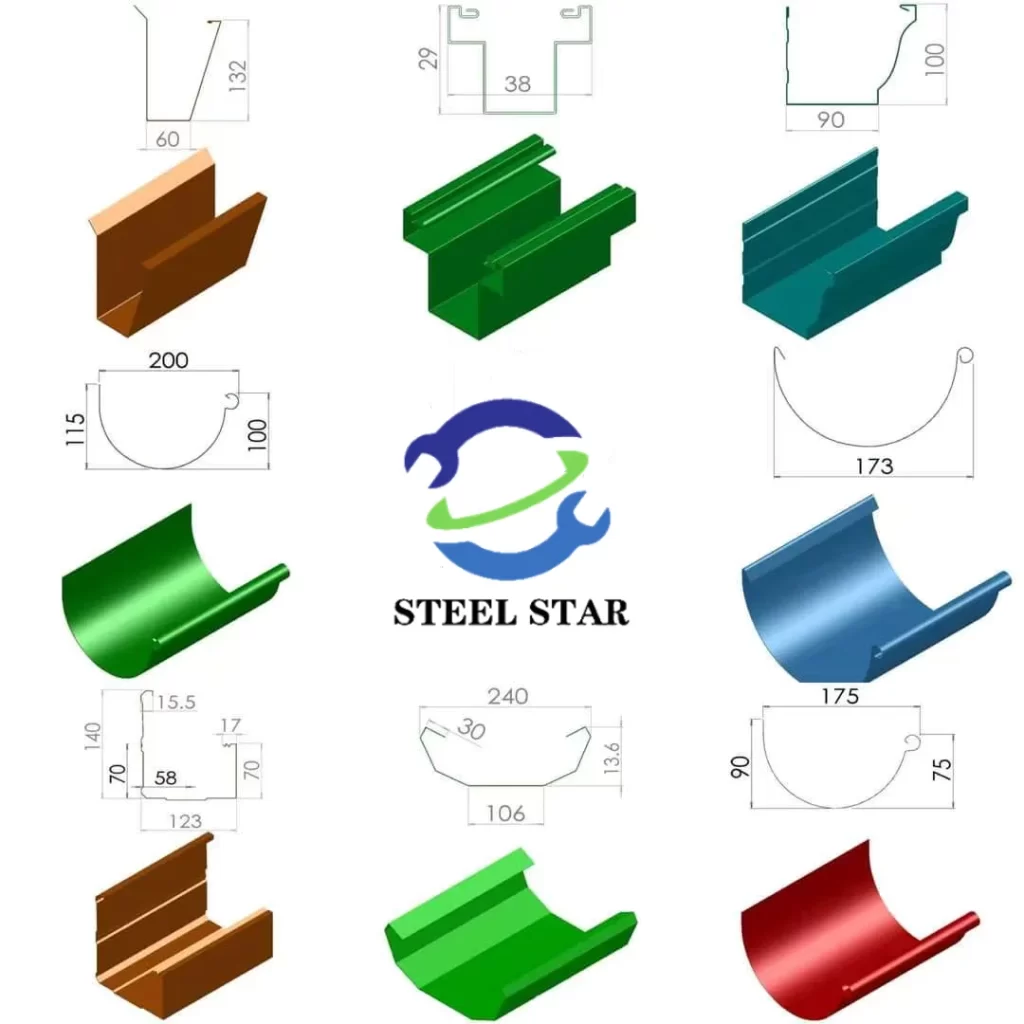

- Progressive Roll Forming: The heart of the machine is the forming mill, consisting of a series of paired roller dies (typically 8 to 16 stands). Each set of rollers makes a slight, calculated bend. As the strip progresses, these incremental bends accumulate to form the complete K-style, half-round, or box-style gutter profile with precise back, bottom, and front apron sections.

- Cutting to Length: After the profile is fully formed, the continuous gutter passes through a cutting system. Most modern machines use a flying cut-off—a synchronized traveling saw or shear that cuts the moving gutter to exact lengths (standard 10ft or 20ft sections) without stopping production, ensuring clean, square ends.

- Output and Handling: The finished gutter sections are conveyed to a stacking table or automated bundler, ready for packaging and shipment. Advanced lines may include automatic stacking and banding.

Key Technical Features and Advantages

- Seamless Production: The primary advantage is the ability to produce long, seamless gutter runs (limited only by transport logistics). This eliminates mid-section leaks common in shorter, pieced-together gutters.

- Precision Tooling: High-carbon steel or chrome-plated forming rolls are machined to exacting tolerances, ensuring every gutter section has identical dimensions, curvature, and appearance. This guarantees proper fit with accessories like corners, end caps, and downspouts.

- Flexibility and Quick Changeover: Many machines are designed for quick-change tooling cassettes, allowing a single production line to switch between different gutter profiles (e.g., from 5-inch K-style to 6-inch half-round) in minutes, maximizing operational flexibility.

- Integrated Automation: Servo-driven punching, programmable length control, and automated stacking minimize labor and maximize output consistency. Production speeds can exceed 100 feet per minute.

- Material Efficiency: The process generates minimal scrap, especially when combined with computer-optimized cutting schedules.

Importance and Market Impact

The machine has revolutionized the gutter industry by enabling:

- Superior Product Quality: Seamless gutters offer enhanced durability, aesthetics, and leak resistance.

- On-Demand, On-Site Production: Many machines are built as portable roll-formers mounted on trailers. Contractors can produce exact required lengths at the job site, eliminating waste, reducing transport damage, and improving service speed.

- Cost-Effective Manufacturing: For large suppliers, stationary high-speed lines provide economies of scale, supplying distributors and big-box retailers with consistent, high-volume product.

The rain gutter roll forming machine is a paradigm of targeted, efficient manufacturing. It elevates a simple functional component into a high-performance, precision-engineered building system. By combining mechanical ingenuity with process automation, it delivers the critical benefits of consistency, strength, and weathertight integrity. Whether as a stationary factory asset or a mobile unit on a contractor’s truck, this machine is the foundational technology behind the modern metal gutter industry, playing a quiet but vital role in protecting structures from water damage worldwide.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)