The Glazed Tile Roll Forming Machine: Engineering Elegance in Metal

Introduction: The Illusion of Craftsmanship

In the realm of architectural roofing and cladding, few materials possess the timeless allure of glazed ceramic tile. For centuries, its vibrant colors, glass-like sheen, and artisanal quality have adorned historic buildings worldwide. However, the traditional process—shaping clay, applying glaze, and kiln-firing at extreme temperatures—is inherently resource-intensive, heavy, and costly. The quest for a material that could replicate this cherished aesthetic while overcoming its practical limitations led to a remarkable feat of engineering: the Glazed Tile Roll Forming Machine.

This sophisticated apparatus does not work with clay or glaze in the traditional sense. Instead, it is the core technology behind the production of metal roofing and wall panels that precisely mimic the three-dimensional profile, shadow lines, and—most crucially—the glossy, variegated visual depth of fired glazed tiles. It represents the pinnacle of modern coil coating and precision metal forming, creating a high-performance building envelope product that balances historical beauty with contemporary engineering.

This article delves into the technology, process, and transformative impact of this specialized machine, explaining how it turns flat, coated steel or aluminum coils into convincing, durable architectural facades.

Part 1: Deconstructing the “Glazed” Illusion: The Coated Coil

The magic begins long before the metal enters the forming machine. The “glaze” on a metal tile is not a ceramic vitreous layer but an advanced, multi-layer coil coating system. Understanding this is key to appreciating the roll former’s role.

A typical substrate is high-strength steel (often G550 grade) or aluminum, pre-finished in a continuous coil coating line that operates as a separate, upstream process:

- Chemical Pretreatment: The metal coil is cleaned and chemically treated to create a micro-surface ideal for paint adhesion and corrosion resistance.

- Primer Application: A corrosion-inhibiting epoxy or chromate-based primer is applied.

- Base Coat & Pattern Printing: Here, the “glazed” effect is born. A solid base color is applied. Then, advanced printing techniques, often using rotary gravure or precision roller coating, apply intricate, multi-tonal patterns. This can replicate the subtle color variegation, mottling, and textural nuances found in hand-crafted glazes—where colors blend and pool, avoiding the flat, uniform appearance of standard paint.

- Top Coat: The “Glaze” Layer: The critical final liquid coat is a high-performance polymer. For a true gloss finish mimicking ceramic glaze, a Polyvinylidene Fluoride (PVDF) or Polyester resin system with a high-gloss modifier is used. This layer is cured to create a hard, exceptionally smooth, and reflective surface. For a granular/metallic glazed look (imitating some stoneware glazes), fine mineral granules or metallic flakes are embedded in this layer.

- Protective Film (Optional): A strippable plastic film is often laminated onto the surface to protect the pristine finish during fabrication, shipping, and installation.

This pre-finished, “glazed” coil—with its complex visual pattern already in place—is the raw material for the roll forming machine. The machine’s task is to form this delicate, decorated surface into a complex 3D shape without scratching, distorting, or damaging the pattern.

Part 2: Anatomy of a Glazed Tile Roll Forming Machine

The machine is a symphony of precision mechanics, careful handling, and digital control. It is more delicate and sophisticated than a standard roofing panel line due to the need to preserve the decorative surface.

Core Components and Process Flow:

1. The Precision Decoiler & Entry Guide:

The process starts with a heavy-duty, tension-controlled decoiler holding the precious coated coil (often 3-10 tons). An entry guide table, equipped with non-marring polymer rollers, ensures the coil feeds into the machine perfectly aligned. Tension is critical: too much can stretch and distort the printed pattern; too little can cause misfeeds.

2. The Embossing Station (Critical for Authenticity):

Before the main forming, the flat sheet often passes through a precision embossing unit. Here, a set of matched male/female steel rollers (or a flat die press) impart a micro-texture onto the metal. This is not the tile profile, but a surface texture—like a subtle hammer-tone, grain, or stipple pattern—that replicates the tactile quality of fired clay and breaks up light reflection to enhance the visual depth of the “glaze.” This step must be perfectly synchronized with the printed pattern.

3. The Heart: The Multi-Stage Roll Forming Mill:

The flat, textured, and printed sheet enters the forming mill, a series of 16 to 24 individual stands, each containing a set of meticulously machined tool steel rollers.

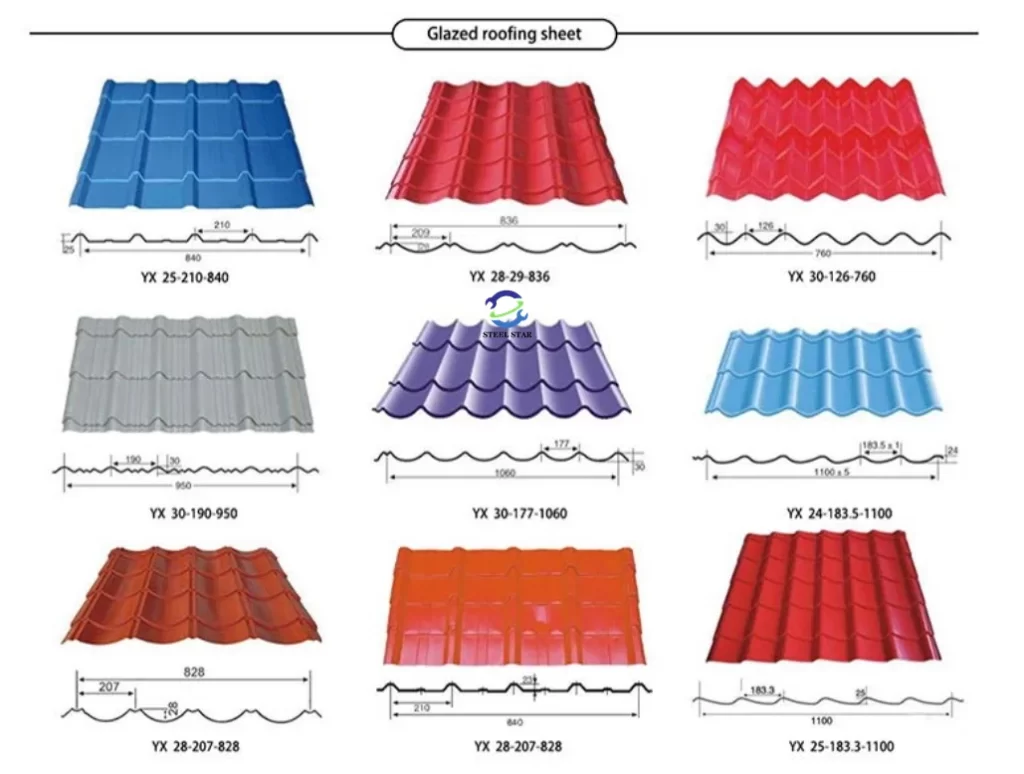

- Progressive Forming: Each stand performs a small, incremental bend. The first stands might start curving the edges that will become the interlocking ribs. Subsequent stands gradually draw the metal up into the high peaks and deep valleys of the tile profile (e.g., Roman, Spanish Barrel, Scallop). The final stands lock in the precise panel shape and the side interlock mechanism—a crucial feature for weathertightness.

- Tooling Design & Finish: The forming rollers are the soul of the machine. They are crafted from hardened tool steel, polished to a mirror finish, and often chrome-plated. This minimizes friction and prevents any scoring or marring of the sensitive coated surface. The roller design is the result of complex CAD/CAM engineering and finite element analysis (FEA) to ensure the metal flows smoothly without stretching the printed pattern.

4. The Servo-Critical Cut-Off System:

Unlike simple corrugated sheets, glazed tile panels must be cut to specific lengths, often with a pattern-matching cut. A standard flying shear is insufficient.

- Pattern Recognition & Servo Control: An optical sensor reads a registration mark on the coil’s edge or the printed pattern itself. A servo-driven hydraulic punch press or a high-precision reciprocating cutter is then synchronized (“flown”) with the moving panel.

- Sculpted Cuts: The cutting die can be shaped to produce a scalloped, tapered, or stepped end cut on the panel, mimicking the irregular lap lines of individual clay tiles. This eliminates a tell-tale straight horizontal line, selling the illusion completely.

5. Output Handling with Kid Gloves:

The finished panels are extremely vulnerable to scratching. The output conveyor is lined with soft materials (urethane, felt). Automated stackers often use vacuum lifters or gentle grippers, and automatic placers insert protective foam or paper between each panel in the stack. The entire line is designed for “top-side-up” forming, ensuring the decorated surface never contacts a hard, potentially abrasive surface.

Part 3: Technical Challenges & Engineering Solutions

Producing a glazed tile effect in metal presents unique hurdles:

- Mar Resistance: The high-gloss finish shows every micro-scratch. Solution: Extensive use of non-contact guiding systems, polished/chromed tooling, and soft-nylon rollers at all touchpoints.

- Pattern Distortion: The stretch and compression of metal during forming can warp the printed design. Solution: Advanced FEA software simulates metal flow during the tooling design phase, ensuring the printed pattern is placed in “neutral” zones of the profile where deformation is minimal.

- Precision & Consistency: The architectural market demands perfect visual alignment. Solution: Closed-loop servo motors on each forming stand and the cut-off press, controlled by a central PLC. This allows for digital recipe recall for different profiles and guarantees that every panel in a project is identical.

- Speed vs. Quality: These lines run slower than standard panel lines (e.g., 20-40 meters per minute vs. 100+ m/min) to ensure careful handling and precision.

Part 4: Advantages and Architectural Impact

The products from this machine have transformed design possibilities:

- Aesthetic Fidelity: Offers an unparalleled replication of historic glazed tile, available in an infinite range of colors and effects (iridescent, metallic, crackle glaze) impossible with ceramic.

- Dramatic Weight Reduction: Metal panels are ~85% lighter than clay tiles, slashing structural support costs and enabling retrofits on older buildings.

- Superior Durability: Rated for severe weather (wind uplift, impact), Class A fire resistance, and impervious to freeze-thaw cycles. The PVDF finish offers 30-40 year warranties against fading and chalking.

- System Integration: Can be integrated with concealed clip systems for a clean, fastener-free appearance, and seamlessly combined with integrated solar panels, snow guards, and ventilation.

- Sustainability: Contains recycled metal, is 100% recyclable at end-of-life, and the reflective “cool roof” options reduce urban heat island effect.

Part 5: The Future: Industry 4.0 and Beyond

The next evolution is already underway:

- Digital Twin & AI Optimization: Running a virtual simulation of the entire forming process to pre-empt defects and optimize tooling designs.

- Inline Digital Printing: Moving beyond pre-printed coils, future lines may incorporate direct-to-metal digital printers just before the embosser, allowing for totally customized, batch-of-one patterns and hyper-realistic designs.

- Augmented Reality (AR) Maintenance: Technicians using AR glasses to see machine diagnostics, tooling wear data, and repair instructions overlaid on the physical line.

The Glazed Tile Roll Forming Machine is more than a factory tool. It is a mediator between history and the future, between artisan craft and digital precision. It solves a fundamental architectural dilemma: how to preserve the aesthetic heritage of our built environment while embracing the demands of modern performance, economics, and sustainability. By mastering the marriage of advanced polymer chemistry, digital printing, and servo-mechanical engineering, this machine produces not just a building component, but an engineered artifact of light, color, and form. It ensures that the timeless beauty of glazed tile can continue to define skylines, not as a relic of the past, but as a resilient, intelligent, and stunningly convincing element of 21st-century architecture.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)