Gutter Rolling Machine: Precision and Efficiency in Modern Rainwater Management

A gutter rolling machine, also known as a gutter forming machine or gutter roll former, is a specialized piece of equipment used to fabricate seamless gutters from flat coils of metal (typically aluminum, galvanized steel, or copper) on-site or in a workshop. This technology revolutionized the roofing and construction industry by enabling the production of long, continuous gutter sections without the seams that are prone to leaks in traditional pre-cut gutters. The resulting seamless gutters offer superior durability, aesthetic appeal, and performance.

How It Works: The Core Process

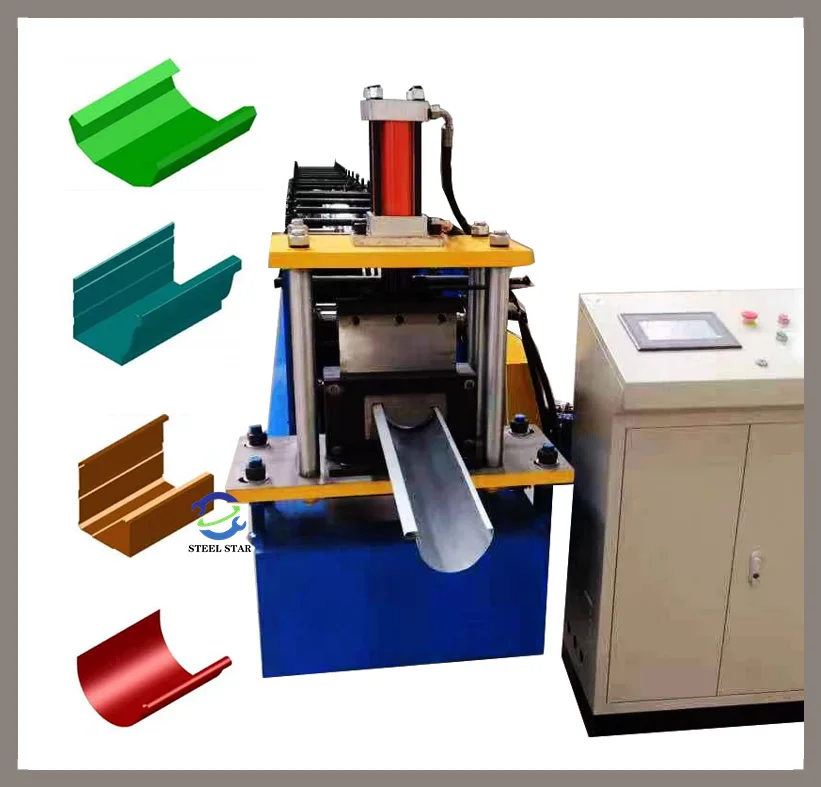

The machine operates on the principle of cold roll forming. A flat metal coil is loaded onto a decoiler. The strip is then fed through a series of precisely engineered roller dies, each station gradually bending the metal until it achieves the desired gutter profile (most commonly K-style or half-round). A high-quality machine integrates several key stations:

- Decoiler: Holds the heavy metal coil.

- Roll Forming Stands: The heart of the machine, containing the roller dies that shape the profile.

- Cutting System: Measures and cleanly cuts the gutter to the exact length required for a specific building section. This can be a hydraulic shear or a servo-controlled flying cut-off saw.

- Control Panel: Modern machines feature a programmable logic controller (PLC) and human-machine interface (HMI) for setting length, quantity, and monitoring operations.

The entire process is continuous, allowing a single operator to produce flawless, custom-length gutters in minutes, drastically reducing material waste and on-site labor time.

Key Benefits of Using a Gutter Rolling Machine

- Seamless Quality: Eliminates mid-section joints, which are the most common failure points for water leakage, leading to longer system lifespan and reduced maintenance.

- On-Demand Customization: Gutters are formed to the exact length needed for each roof run, minimizing seams (only at corners and downspout outlets) and ensuring a perfect fit.

- Material Efficiency: Reduces waste significantly compared to working with standard pre-cut lengths.

- Professional Edge: Enables contractors to offer a premium, durable product, enhancing their service portfolio and profitability.

- Operational Efficiency: Increases installation speed and reduces crew size requirements on job sites.

Types and Applications

Gutter rolling machines are categorized by their power source, mobility, and profile capability:

- Manual / Hand-Crank Machines: Portable, low-cost units suitable for very small operations or occasional use. They require significant operator effort.

- Electric-Powered Machines: The most common type for professional contractors. They offer an optimal balance of power, portability (often trailer-mounted), and efficiency.

- Heavy-Duty / Industrial Machines: Larger, stationary machines used in manufacturing facilities for high-volume production. They can handle thicker metals and multiple profiles.

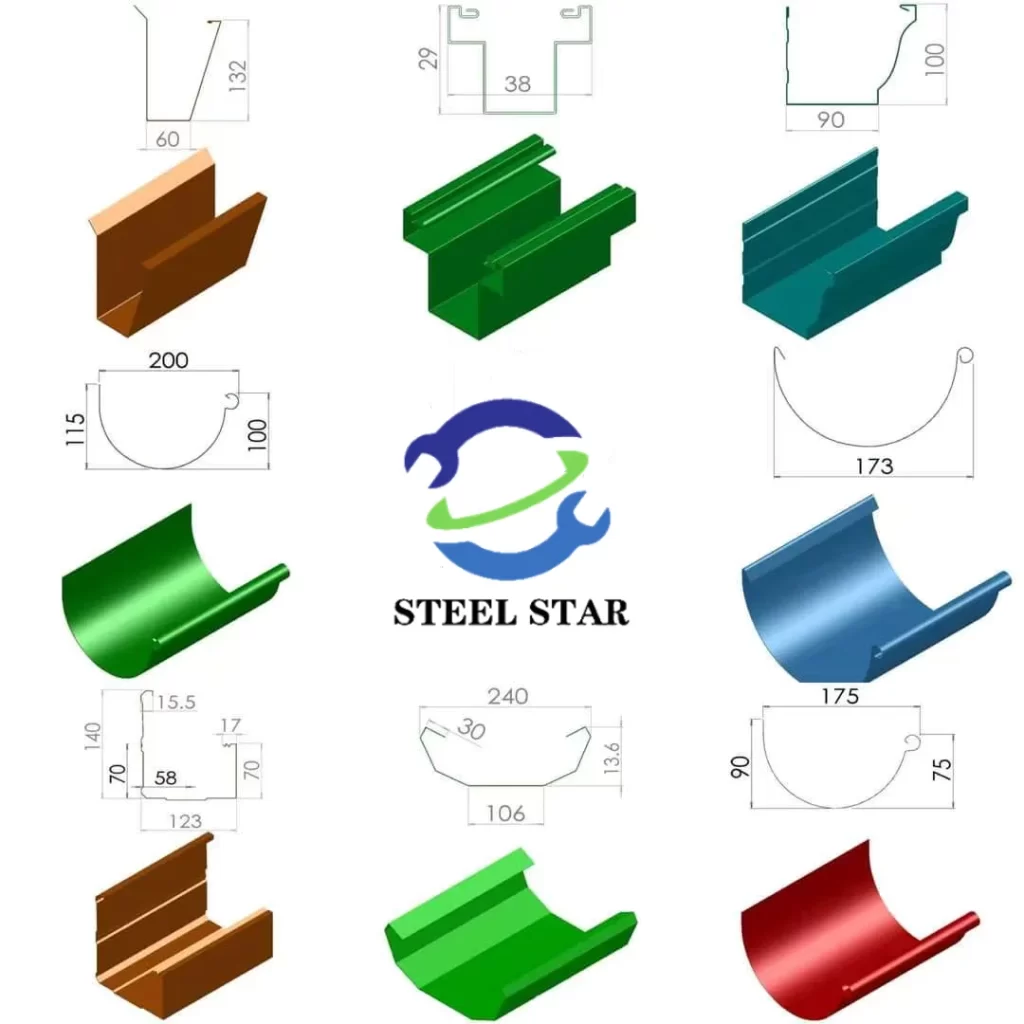

- Profile Variety: Modern machines can often be configured with different roller die sets to produce K-style (the most popular residential profile with a decorative front), half-round gutters (common in historical or high-end architecture), and fascia-style gutters.

Critical Factors Influencing Machine Selection and Investment

When purchasing a gutter rolling machine, consider these factors which directly impact capability, price, and return on investment:

- Material Type and Gauge: Ensure the machine can handle your preferred metal (e.g., aluminum, painted Galvalume®) and its thickness (e.g., .027″ or 0.7mm for aluminum).

- Profile Versatility: Ability to form different gutter styles and sizes (e.g., 5-inch vs. 6-inch K-style).

- Portability & Power Source: For contractors, a trailer-mounted, electric-powered unit running on standard 110V/220V power is ideal.

- Production Speed and Accuracy: Look for features like digital length input, servo-driven cut-off systems, and consistent forming quality.

- Build Quality and Support: A robust steel frame, hardened alloy steel rollers, and reliable components from a manufacturer with strong technical and spare parts support are crucial for longevity.

Market Considerations and ROI

The price range for a professional-grade electric gutter roll former typically falls between $8,000 and $25,000, depending on features, brand, and capability. For a roofing or siding contractor, the investment is often quickly offset by:

- Higher profit margins on seamless gutter installations.

- Reduced labor costs and faster job completion.

- Competitive advantage and the ability to offer a superior product.

- Reduced callbacks due to leaks.

The gutter rolling machine is more than just a tool; it is a cornerstone of modern, efficient rainwater management systems. By bringing precision manufacturing directly to the job site, it empowers contractors to deliver seamless, durable, and custom-fitted gutters that protect buildings effectively. For businesses in the roofing and construction sector, investing in this technology represents a strategic move toward higher quality, greater operational efficiency, and enhanced customer satisfaction. As building standards continue to emphasize durability and performance, the role of the gutter rolling machine in creating reliable water-handling systems remains indispensable.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)