Deck Floor Forming Machine: Engineering Efficiency in Modern Construction

A deck floor forming machine, also known as a floor deck roll forming machine or metal decking production line, is a specialized industrial machine designed to continuously transform flat steel coils into profiled steel decking sheets. These sheets are a critical structural component in modern commercial, industrial, and multi-story residential construction, serving as permanent formwork for concrete slabs and providing structural reinforcement. This technology is central to the speed, economy, and strength of composite floor systems.

The Core Technology: Process and Function

The machine operates on the principle of precision cold roll forming. A coil of galvanized or painted steel (typically 0.7mm to 1.5mm thick) is fed from a decoiler through a progressive series of roller dies. Each set of rolls incrementally bends the steel until it achieves the desired trapezoidal or re-entrant profile. A complete, automated production line integrates several key stations:

- Loading & Decoiling: A hydraulic or motorized decoiler handles heavy steel coils (weighing several tons).

- Roll Forming Station: The heart of the machine, consisting of 15-25 pairs of hardened steel rolls mounted on a robust frame. These progressively shape the metal into the precise deck profile.

- Cutting System: A high-precision hydraulic flying cut-off system or a servo-controlled shear cuts the continuously formed sheet to pre-set lengths (typically 3-12 meters) without stopping the line, ensuring clean, burr-free edges.

- Control System: A centralized PLC (Programmable Logic Controller) with an HMI (Human-Machine Interface) panel allows operators to input sheet length, quantity, and production speed, ensuring consistency and repeatability.

- Output & Stacking: An automatic run-out table and stacking system organize the finished sheets for bundling and shipping.

Key Benefits and Applications of Machine-Produced Decking

- Structural Efficiency: The formed profiles (ribs) create a high strength-to-weight ratio, allowing for longer spans between supports and reducing the need for secondary beams.

- Construction Speed: Deck sheets act as permanent formwork, eliminating the need for traditional wooden forms and shoring, drastically accelerating the construction cycle.

- Composite Action: When welded to the supporting steel beams and filled with concrete, the deck’s embossments create a strong mechanical bond, resulting in a composite slab with exceptional load-bearing capacity.

- Multi-Functionality: The deck provides an immediate safe working platform, incorporates utilities (electrical conduits, HVAC) within its depth, and can accommodate fireproofing.

- Material Consistency: Roll forming ensures every sheet has identical dimensions and mechanical properties, critical for structural integrity and predictable on-site performance.

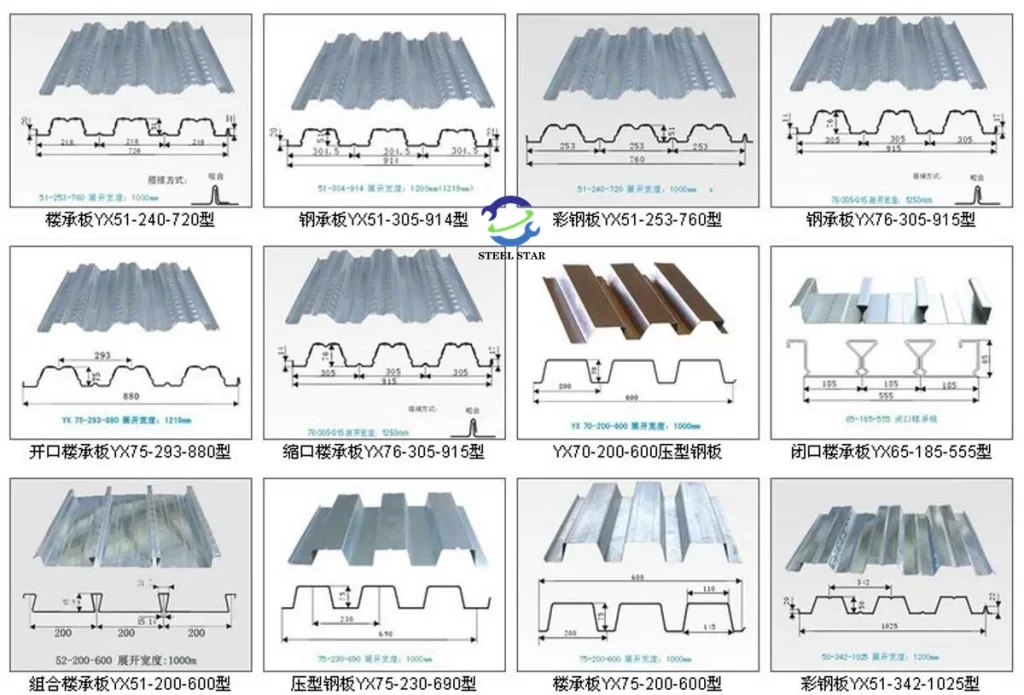

Types of Deck Profiles and Machine Versatility

Modern machines are configured to produce various standardized profiles:

- Composite Deck (Trapezoidal): The most common type, with wide ribs designed for optimal composite action with concrete. Common depths: 50mm, 60mm, 75mm.

- Form Deck (Non-Composite): Used as permanent formwork for concrete slabs in non-composite applications, often with a narrower rib.

- Cell Deck (Re-entrant): Features a closed-cell profile, ideal for creating very long spans and housing services.

- Roof Deck: Similar profiles but often with different coatings and considerations for waterproofing and insulation attachment.

High-end machines offer quick-change roll systems, allowing a single production line to manufacture multiple profiles with minimal downtime for retooling.

Critical Factors in Machine Selection and Investment

Investing in a deck floor forming line is a major capital decision. Key considerations include:

- Production Capacity: Determined by line speed (e.g., 20-40 meters per minute), material thickness range, and coil weight capacity.

- Profile Flexibility: Number of different deck profiles and depths the machine can produce.

- Automation Level: Degree of automation in coil loading, length measurement, cutting, and stacking. Higher automation reduces labor and improves safety.

- Control System & Precision: Advanced servo drives and CNC controls ensure cutting length accuracy (±1mm) and consistent profile geometry.

- Build Quality & Durability: The rigidity of the frame, quality of the gearboxes, and hardness of the roller dies determine machine longevity and maintenance costs.

- Manufacturer Support: Access to technical service, spare parts, and engineering support for profile design is crucial.

Economic and Industry Impact

A deck floor forming machine represents a significant investment, typically ranging from $150,000 to over $500,000 for a fully automated, high-capacity line. However, for manufacturers, the return on investment is driven by:

- Meeting Large-Scale Demand: Ability to supply major commercial and infrastructure projects.

- Material Yield Optimization: Precise control minimizes steel waste.

- Competitive Advantage: Offering consistent quality, timely delivery, and a variety of profiles.

For the construction industry at large, the widespread use of machine-produced metal decking has enabled taller, lighter, and faster-built structures, fundamentally shaping modern skylines.

The deck floor forming machine is a quintessential example of industrial innovation directly enabling advancements in construction methodology. It transforms raw steel into a highly engineered, value-added product that forms the very floors of modern buildings. By combining precision engineering, automation, and material science, this technology not only fuels a vital manufacturing sector but also provides the construction industry with a component that is synonymous with efficiency, strength, and speed. As sustainable and modular construction practices evolve, the role of the roll-formed metal deck—and the machines that produce it—will continue to be foundational.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)