Downspout Forming Machine: Engineering Efficient Water Management

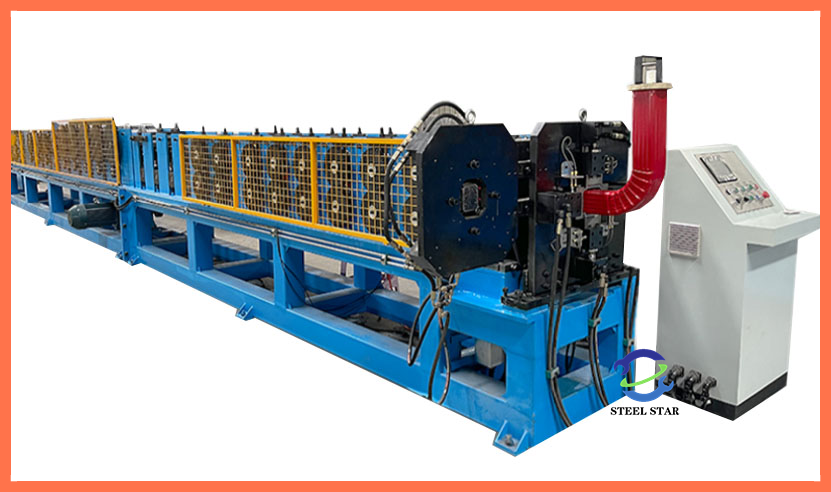

A downspout forming machine, also known as a downpipe roll forming machine, is a specialized piece of equipment designed to manufacture the vertical piping components of a rainwater drainage system from flat metal coils. This machinery transforms raw materials—typically galvanized steel, aluminum, or copper—into precisely formed downspouts that channel water from roof gutters safely to the ground or drainage system. As an integral part of the gutter production ecosystem, downspout formers enable contractors and manufacturers to produce seamless, custom-length downspouts on-site or in-factory, ensuring optimal fit, durability, and aesthetic consistency with associated gutter systems.

Technical Process and Machine Configuration

The downspout forming process is a continuous, automated operation based on precision cold roll forming technology. A typical production line integrates several sequential stations:

- Coil Loading & Decoiling – A hydraulic or motorized decoiler supports heavy metal coils (often weighing 1–3 tons) and feeds the strip into the machine.

- Roll Forming Stations – The heart of the machine, where 8–16 pairs of hardened alloy steel rollers progressively shape the metal into standardized or custom downspout profiles (common shapes include rectangular, round, and corrugated designs).

- Punching & Notching Unit – A servo-driven punching system creates precise outlets for connecting elbows, offsets, and shoe pieces, as well as holes for mounting brackets.

- Cut-off System – A hydraulic flying shear or servo cut-off mechanism accurately cuts the downspout to pre-set lengths without stopping the line, ensuring clean, burr-free ends.

- Control System – A centralized PLC and HMI interface allows operators to control dimensions, punching patterns, length, and production speed.

- Output Conveyor & Stacker – Automatically organizes finished downspouts for bundling.

Key production specifications include:

- Common sizes: 2″×3″, 3″×4″, 4″×5″ (rectangular); 3″, 4″, 5″ diameters (round)

- Material thickness: 0.4mm–0.8mm for aluminum; 0.5mm–0.7mm for galvanized steel

- Standard length: 8–12 feet (customizable)

- Line speed: 10–30 meters per minute

Types of Downspout Forming Machines

Machines vary by application scale, mobility, and profile versatility:

- Portable / Jobsite Machines – Compact, trailer-mounted units designed for on-site fabrication by contractors. Often electric-powered and capable of producing standard rectangular profiles.

- Stationary Industrial Machines – Heavy-duty factory-based lines with higher automation, capable of running multiple profiles (rectangular, round, corrugated) and integrating auxiliary operations like embossing or painting.

- Integrated Gutter & Downspout Systems – Combined production lines that manufacture both gutters and matching downspouts in a continuous workflow, ensuring system compatibility and efficiency.

Key Benefits in Construction and Manufacturing

- Seamless Customization – Enables production of exact downspout lengths required for each building, minimizing joints and potential leak points.

- Material Efficiency – Reduces waste compared to working with pre-cut sections and allows optimization of coil usage.

- Enhanced Durability – Seamless, continuously formed downspouts exhibit superior structural integrity and corrosion resistance at seams.

- Professional Aesthetics – Consistent profiles and precise dimensions ensure a clean, uniform appearance.

- Operational Efficiency – Significantly reduces installation time and labor compared to assembling pre-fabricated sections.

Market Applications

Downspout forming machines serve a range of sectors:

- Roofing & Gutter Contractors – On-site fabrication for residential and commercial projects.

- Metal Fabrication Shops – Production of downspouts for wholesale distribution.

- Pre-Engineered Building Manufacturers – Integrated production of complete rainwater management systems.

- Renewable Energy Sector – Fabrication of drainage components for solar panel installations and large-span structures.

Selection Criteria and Investment Considerations

When selecting a downspout forming machine, key factors include:

- Material Compatibility – Ability to process the preferred metal type and thickness.

- Profile Flexibility – Support for multiple downspout shapes and sizes.

- Automation Level – Degree of automation in punching, cutting, and stacking.

- Portability & Power Requirements – Critical for contractors needing jobsite mobility.

- Tooling Quality & Support – Durability of rolls and dies, and availability of technical service.

Pricing typically ranges from $15,000 for basic portable models to $80,000+ for high-speed, multi-profile industrial lines. Return on investment is driven by reduced labor costs, minimized material waste, and the ability to offer premium seamless systems.

Technological Trends and Future Outlook

Recent advancements include:

- Servo-Driven Punching Systems – For complex, programmable hole patterns.

- Touch-Screen PLC Controls – With memory storage for custom profiles and lengths.

- Quick-Change Roll Systems – Allowing faster transitions between profile sizes.

- IoT Connectivity – For remote monitoring, diagnostics, and production analytics.

As sustainable construction practices and resilient infrastructure gain emphasis, downspout forming machines will continue to evolve—incorporating energy-efficient drives, compatibility with recycled metals, and enhanced precision for optimal hydraulic performance.

The downspout forming machine embodies the synergy between precision engineering and practical construction needs. By enabling efficient, on-demand production of tailored rainwater management components, it not only elevates the quality and reliability of drainage systems but also empowers contractors and manufacturers with greater control over cost, timeline, and performance. In an era where water management is increasingly critical to building sustainability and resilience, this technology stands as a vital tool in the construction industry’s ongoing pursuit of efficiency, durability, and excellence.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)