The Double Layer Roof Sheet Machine: Engineering Precision for Modern Construction.

In the realm of modern construction and architectural design, the demand for durable, aesthetically pleasing, and efficient building materials is constant. Standing at the intersection of innovation and practicality is the Double Layer Roof Sheet Machine, a specialized piece of industrial equipment that has revolutionized the production of a key architectural component: the double-layer roof sheet.

What is a Double Layer Roof Sheet?

Before delving into the machine, it is essential to understand its product. A double-layer roof sheet is a formed metal panel, typically made from materials like galvanized steel, aluminum, or zinc-aluminum alloys. Its defining feature is a two-layer construction with an air gap or insulation cavity between them. This design offers superior thermal insulation, noise reduction, condensation control, and enhanced structural rigidity compared to single-layer sheets. They are widely used in factories, warehouses, commercial complexes, and cold storage facilities.

The Core Function of the Machine

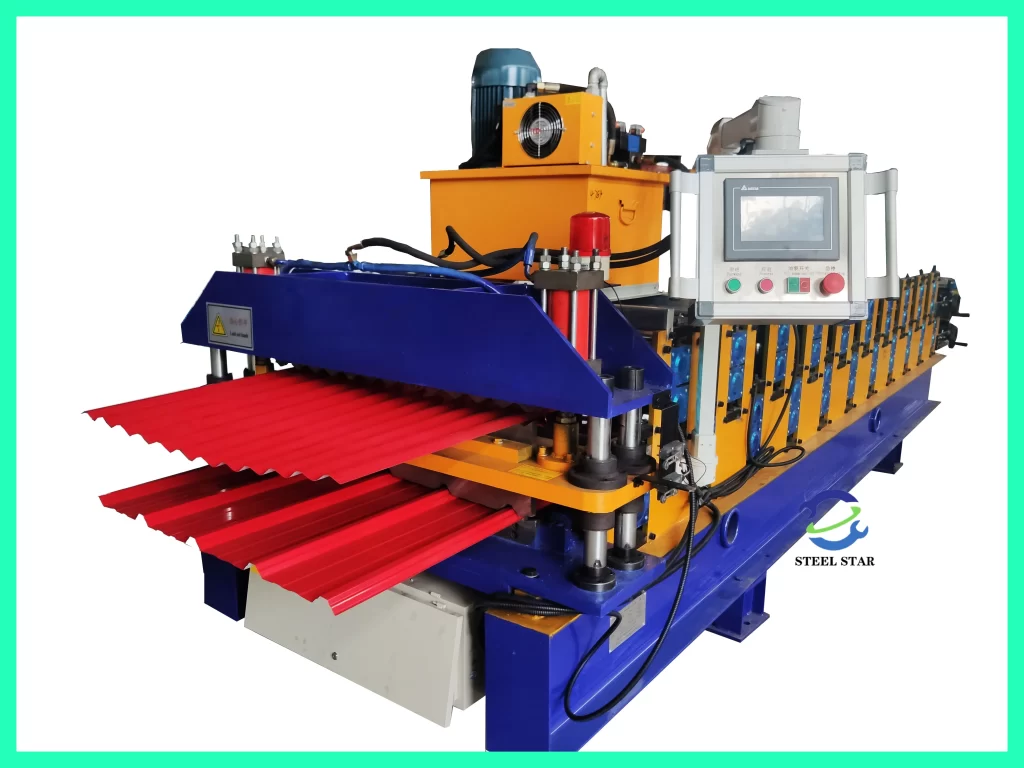

A Double Layer Roof Sheet Machine is a fully automated, continuous roll-forming production line. Its primary function is to transform flat metal coils into precise, high-quality double-layer roof panels in one seamless operation. The machine integrates several stages into a synchronized system:

- Uncoiling and Feeding: The process begins with heavy-duty decoilers that hold and feed the large metal coils into the line. A precision feeding and levelling system ensures the metal strip is perfectly flat before forming.

- Pre-Punching (Optional): For sheets requiring ventilation or specific fixing points, a servo-controlled punching station can perforate the inner layer with accuracy before the forming process.

- Roll-Forming Stations – The Heart of the Machine: This is where the magic happens. A series of meticulously engineered roll-forming stands, equipped with hardened steel rollers, progressively bend the metal strip. One set of rollers forms the inner layer profile, while another simultaneous or sequential set forms the outer layer profile. The precision of these rollers dictates the final sheet’s dimensional accuracy and consistency.

- Layer Integration and Seaming: The formed inner and outer layers are guided together. A critical component is the seaming or closing station, which mechanically locks the two layers at their edges, creating the sealed air gap. Different machines offer various seam profiles (e.g., mechanical lock, snap-on) for different performance needs.

- Cutting to Length: A high-precision hydraulic or servo flying cut system cuts the continuously formed panel to pre-set lengths without stopping the production line, ensuring clean, burr-free edges.

- Output and Stacking: The finished panels are automatically conveyed to a stacking table, where they are neatly arranged for packaging, storage, and shipment.

Key Advantages and Technical Features

- High Efficiency & Speed: These automated lines can produce panels at impressive speeds (often 30-80 meters per minute), dramatically increasing output and reducing labor costs.

- Exceptional Consistency: Once calibrated, the machine produces thousands of panels with identical profiles, tolerances, and seam integrity, ensuring quality across entire roofing projects.

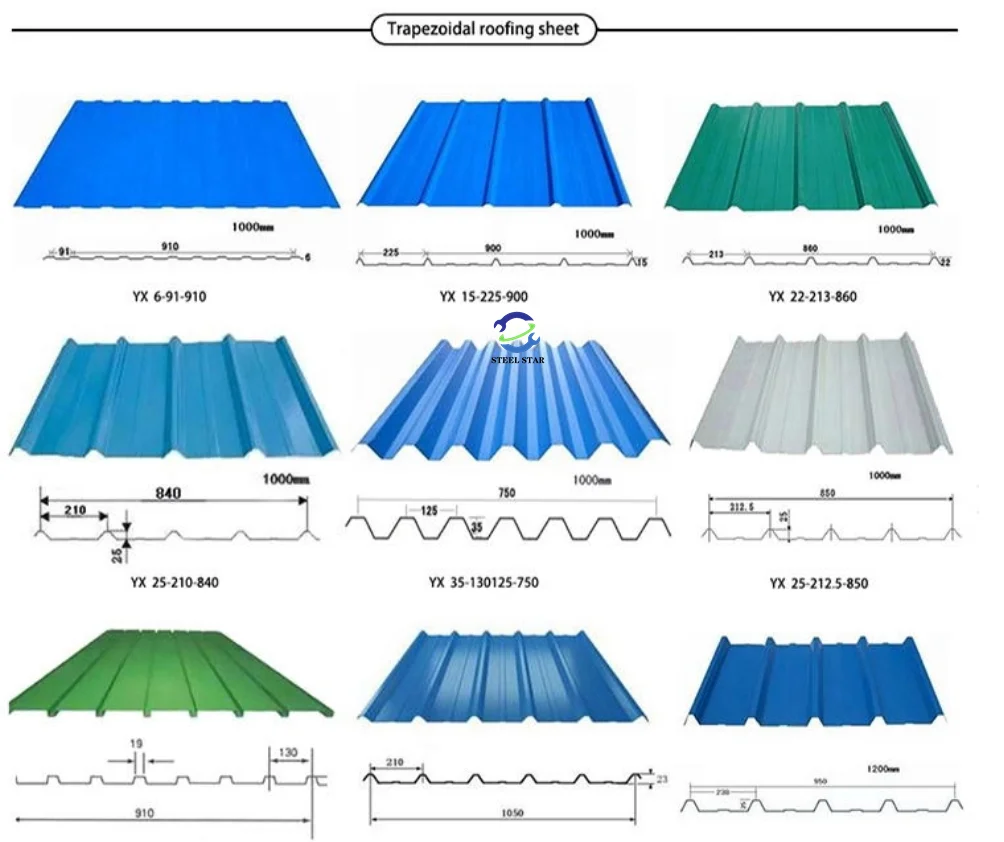

- Design Flexibility: By changing the roll-forming tool sets, a single machine can produce a variety of profiles, widths, and layer heights, allowing manufacturers to cater to diverse market demands.

- Material Efficiency: The process minimizes waste through precision feeding and cutting, optimizing raw material usage.

- Integrated Automation: Modern machines are controlled by PLC (Programmable Logic Controller) systems with touch-screen HMIs (Human-Machine Interfaces). This allows for easy parameter setting, fault diagnosis, and production monitoring.

Impact on the Construction Industry

The widespread adoption of machines producing double-layer sheets has had a profound impact:

- Energy-Efficient Buildings: By facilitating the production of superior insulating roof panels, these machines contribute directly to the construction of energy-saving buildings, lowering heating and cooling costs.

- Faster Construction: Pre-formed, high-quality panels enable faster installation on-site, reducing overall project timelines.

- Architectural Versatility: The availability of various colors, finishes (e.g., PVDF coated), and profiles allows architects greater creative freedom while maintaining performance.

- Durability and Longevity: The controlled production ensures panels that are resistant to weather, corrosion, and structural fatigue, leading to longer-lasting roofs.

The Double Layer Roof Sheet Machine is more than just a manufacturing tool; it is an enabler of advanced, sustainable construction. By combining mechanical engineering, precision machining, and automated control, it transforms raw metal into intelligent building envelopes. As the global focus on energy efficiency and rapid, quality construction intensifies, the role of this sophisticated equipment will only become more central, quietly shaping the skylines of our cities and the efficiency of our industrial spaces from the ground up.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)