The Art and Science of Gutter Forming: Shaping Modern Water Management

In the world of building construction and home improvement, few components are as simultaneously mundane and vital as the gutter system. Acting as the first line of defense against water damage, gutters are meticulously shaped channels that protect roofs, walls, and foundations by directing rainwater away from structures. At the heart of their reliable and efficient production lies the specialized process of gutter forming.

What is Gutter Forming?

Gutter forming is a highly automated, continuous manufacturing process that transforms flat coils of metal—primarily aluminum, galvanized steel, or copper—into seamless, uniform gutter profiles of specific shapes and lengths. This is primarily achieved through a manufacturing technique called roll forming.

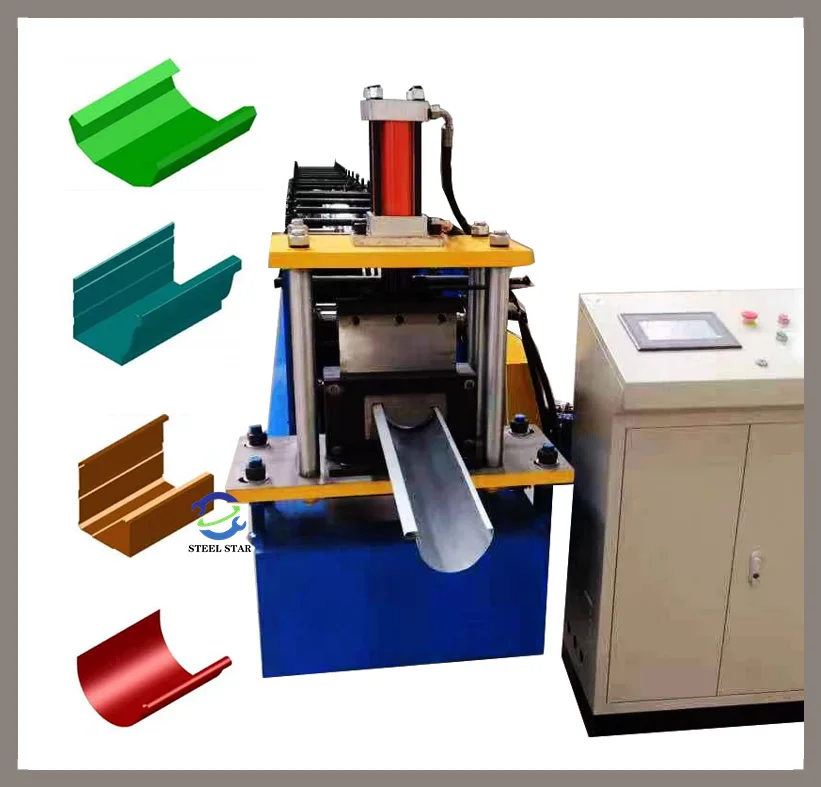

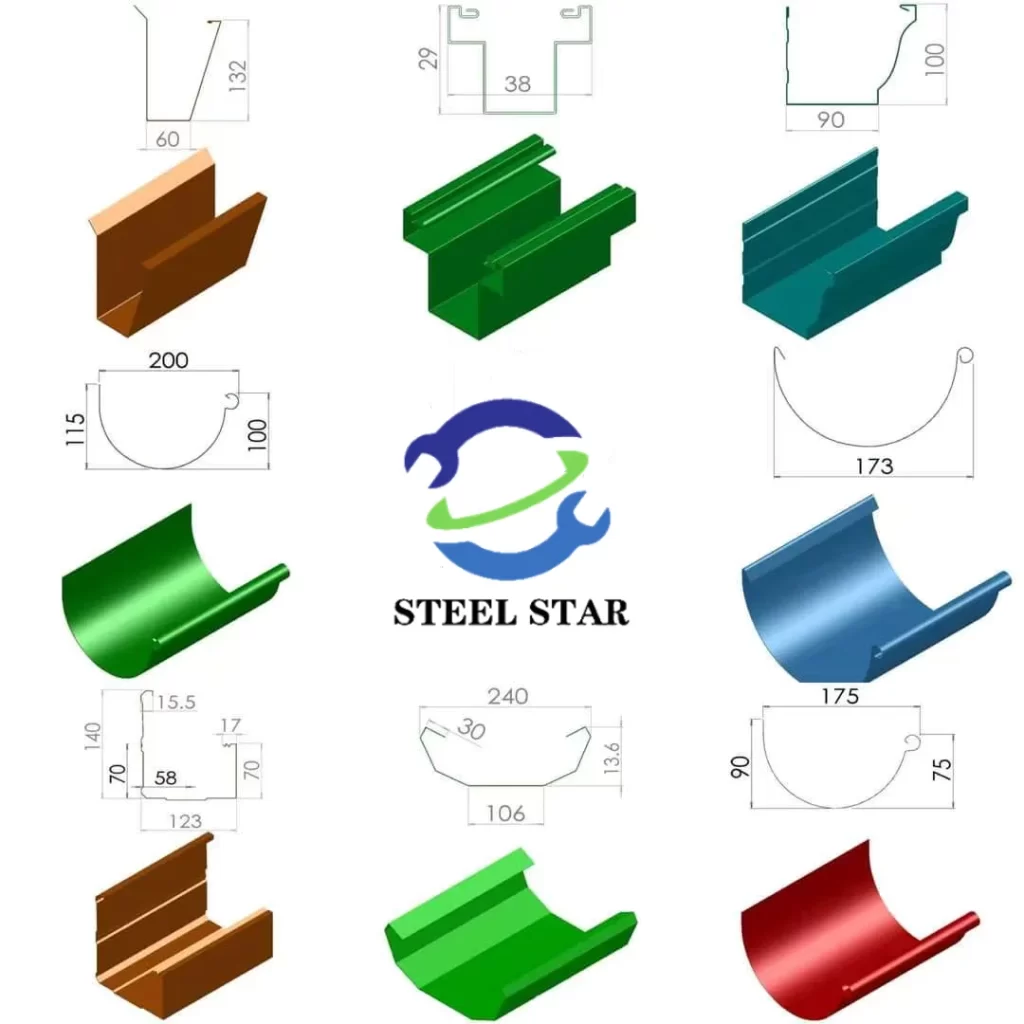

A gutter roll forming machine is the centerpiece of this operation. It consists of a series of paired, contoured roller dies mounted on a sturdy frame. A flat metal strip is fed from a decoiler into the machine. As it passes through each consecutive set of rollers, the metal is incrementally and precisely bent without stretching or cutting. With each station, the cross-section progressively takes on the final gutter shape, whether it be the classic K-style (ogee), the efficient half-round, or the utilitarian box-style fascia gutter.

A critical feature of modern on-site gutter machines is their ability to produce seamless gutters. Unlike sectional gutters joined with seams (potential leak points), these are formed in continuous lengths, often up to 50 feet or more, directly on the job site. This eliminates intermediate seams along the run, significantly enhancing durability and leak resistance.

The Forming Process: Step-by-Step

- Material Loading & Feeding: A coil of pre-painted or mill-finish metal is mounted on a decoiler. The leading edge is fed into the straightening and feeding mechanism of the roll former.

- Pre-Notching/Punching (Optional): For customized installations, the machine may incorporate a punching station to create downspout outlet holes or miter notches at precise intervals before the forming begins.

- Progressive Roll Forming: The heart of the process. The metal strip travels through 10-20+ pairs of powered rollers. Each station performs a minor bend, gradually shaping the metal’s cross-section into the complete profile with precise angles and radii.

- Cut-Off: Once the formed gutter reaches a pre-set length, a synchronized hydraulic or pneumatic cut-off mechanism cleanly shears it without crushing the profile. The process then continues seamlessly for the next length.

- Finishing & Handling: The finished gutter section is supported and ejected. On-site, it is ready for immediate installation. In a factory setting, end caps, seals, and other hardware might be added before packaging.

Key Advantages of Modern Gutter Forming

- Seamless Construction: The most significant benefit, eliminating longitudinal seams and drastically reducing failure points.

- Customization & Efficiency: Lengths are formed to exact measurements for each roof run, minimizing waste and on-site labor for joining sections. Profiles, colors, and gauges can be selected per project.

- Strength & Consistency: The cold-forming process work-hardens the metal slightly, and the roll-formed shape creates a structurally rigid profile. Every inch meets identical tolerances.

- Material Versatility: The process is adaptable to various ductile metals, allowing for choices based on budget (aluminum), strength (steel), or aesthetics (copper).

- Speed & Economics: High production speed, minimal material waste, and reduced installation time make it a cost-effective solution for both manufacturers and contractors.

Applications Beyond the Basic

While residential K-style gutters are the most common output, gutter forming technology serves diverse needs:

- Commercial & Industrial Buildings: Producing larger box gutters and heavy-duty rainwater systems.

- Specialty Profiles: Creating historical reproductions for renovation projects.

- Integrated Systems: Forming gutters with built-in leaf guards or heating element channels.

Gutter forming is a perfect example of applied industrial engineering solving a persistent practical problem. It elevates a simple drainage component into a reliable, high-performance building system. By combining precision mechanics with durable materials, this process ensures that the gutters protecting our homes and structures are not afterthoughts, but optimally engineered elements formed for longevity and performance. From the relentless rollers of the forming machine emerges a simple channel that, once installed, silently and efficiently performs the critical duty of water management for decades.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)