Navigating the Cost of Roofing Sheet Roll Forming Machines

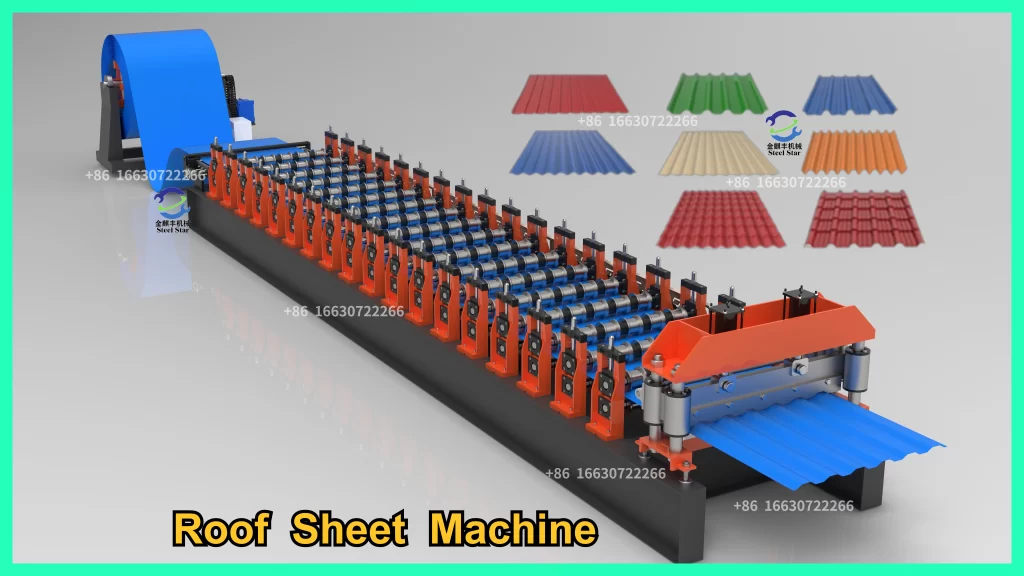

The roofing sheet roll forming machine is the industrial workhorse behind the corrugated metal roofs seen on warehouses, factories, agricultural buildings, and modern homes. For businesses entering the manufacturing sector or expanding their production capacity, understanding the price landscape of these machines is crucial. The cost is not a single figure but a spectrum, influenced by a complex interplay of technical specifications, automation levels, and market factors.

The Price Spectrum: From Basic to Fully Automated

Prices can range dramatically, typically from as low as $8,000 for a basic, manual-entry machine to over $250,000 for a high-speed, fully automated production line. This broad range can be broken down into several tiers:

- Entry-Level / Manual Machines ($8,000 – $50,000):

- Description: These are often simple, bench-top or light-duty machines with a limited number of forming stations (e.g., 10-14). They require manual feeding of pre-cut sheets and manual operation of the cut-off system.

- Ideal For: Small workshops, on-site fabrication for specific projects, or producers with very low-volume, customized orders.

- Trade-offs: Lower output, higher labor intensity, and less consistency in final product length.

- Mid-Range / Semi-Automatic Machines ($50,000 – $120,000):

- Description: This is the most common category for serious manufacturers. It includes a decoiler for coil feeding, a robust roll forming mill with more stations (16-22), and an automated, computer-controlled flying cut-off system for precise length cutting without stopping the line.

- Ideal For: Small to medium-sized roofing sheet manufacturers supplying regional markets. They offer a strong balance of productivity, quality, and affordability.

- Key Features: Programmable Logic Controller (PLC), hydraulic or servo cut-off, and the ability to produce multiple profiles with roll changes.

- High-End / Fully Automated Lines ($120,000 – $500,000+):

- Description: These are complete, turnkey systems designed for uninterrupted, high-volume production. They integrate additional modules like an automatic coil loading car, in-line punching or embossing stations, automatic stacking systems, and sophisticated packaging conveyors.

- Ideal For: Large-scale manufacturers supplying national markets or major construction projects. They maximize output and minimize direct labor.

- Key Features: High-speed servo drives, advanced HMI touchscreen controls, production data tracking, and compatibility with Industry 4.0 protocols.

Key Factors Determining the Price

- Machine Capacity & Speed:

- Material Thickness & Width: Machines capable of forming thicker (e.g., 2.0mm vs. 0.3mm) and wider steel coils command a higher price due to heavier frames and more powerful drives.

- Line Speed: A machine rated for 30 meters per minute is significantly less complex than one running at 100+ meters per minute, impacting the cost of drives, controls, and cutting synchronization.

- Automation & Control Systems:

- The type of cut-off system (simple hydraulic vs. high-precision servo) is a major cost driver.

- The sophistication of the PLC and Human-Machine Interface (HMI) for storing profiles and monitoring diagnostics adds cost.

- Integration of auxiliary equipment (auto-stacking, packaging) dramatically increases the total system price.

- Profile Complexity & Flexibility:

- A machine dedicated to a single, simple corrugated profile is less expensive than a multi-profile machine.

- Machines with a “quick-change” roll system for switching between different roof sheet designs (e.g., from a classic corrugated to a standing seam trapezoidal panel) require more engineering and higher costs.

- Build Quality & Origin:

- Brand & Engineering: Established European or North American brands often carry a premium due to engineering heritage, material quality, and after-sales support.

- Geographical Manufacturing: Machines from China or other Asian manufacturing hubs can offer competitive pricing, but due diligence on component quality, technical support, and shipping/import duties is essential.

- Core Components: The quality of the electrical systems (e.g., Siemens), bearings, and hydraulic units directly affects reliability and price.

- Additional Costs (The Hidden Factors):

- Shipping, Insurance, and Installation: For international purchases, these can add 15-30% to the base price.

- Training & Commissioning: Professional on-site setup and operator training are critical and often quoted separately.

- Spare Parts & Tooling: An initial set of spare rollers, blades, and hydraulic seals should be budgeted for. Additional roll sets for new profiles are a separate, significant investment.

- Local Certification & Compliance: Meeting local electrical and safety standards may require modifications.

Investment Perspective: Total Cost of Ownership

The smart buyer evaluates the Total Cost of Ownership (TCO), not just the purchase price. A cheaper machine with frequent downtime, high energy consumption, poor material yield (waste), and lacking technical support can be far more expensive in the long run than a higher-priced, reliable, and efficient system.

There is no one-size-fits-all price for a roofing sheet roll forming machine. The investment is directly proportional to the production goals, desired quality, and level of operational autonomy. Prospective buyers must clearly define their target market, required output, and product range before engaging with suppliers. Requesting detailed quotations that break down machine specifications, warranties, and support terms is essential. Ultimately, the right machine is an investment that balances upfront cost with long-term productivity, reliability, and profitability, forming the very foundation of a successful metal roofing business.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)