The Steel Slitting Line: Precision at the Heart of Metal Processing

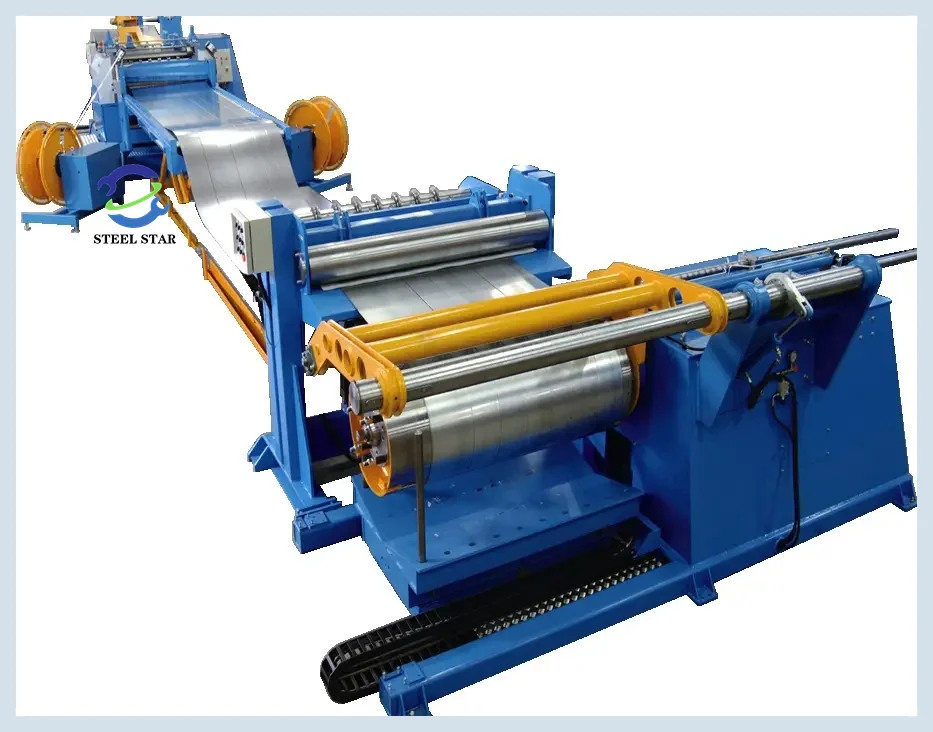

The steel slitting line machine is an indispensable workhorse in modern metal fabrication, serving as the critical first step in transforming wide master coils into narrower, more manageable strips for countless downstream applications. Operating with high speed and precision, this machine is the backbone of efficient material flow in industries ranging from automotive and construction to appliances and container manufacturing.

Core Function and Process Flow

A steel slitting line is designed to longitudinally cut (or “slit”) a wide coil of steel into multiple narrower strips of precise width. The fundamental process follows a carefully engineered sequence:

- Loading/Uncoiling: A heavy-duty mandrel or cantilevered uncoiler holds and feeds the master coil, typically weighing several tons, into the line.

- Flattening & Alignment: The steel passes through a leveler or “flattener” consisting of a series of small-diameter rolls that remove coil set (inherent curvature) and any crossbow or camber. A threading table with edge guides ensures the strip enters the cutting section perfectly aligned.

- The Heart of the Line: Slitting. The strip enters the slitter head, the machine’s core component. Here, two parallel arbors (shafts) hold sets of matched, hardened steel circular knives.

- The top arbor holds the male knives (overlap knives).

- The bottom arbor holds the female knives (driven knives).

- The gap and overlap between these precisely ground knives are set to the desired strip width and material thickness. As the metal passes through, the knives make clean, longitudinal cuts.

- Separation & Tension Control: The newly slit strands are separated by a threading system or stripper ring to prevent interlace and scratching. A drag unit or tension stand then applies controlled back tension to keep the strands taut and aligned.

- Rewinding: The individual strands are wound onto separate rewind mandrels to form new, narrower coils. Advanced lines feature dual rewind heads for continuous operation: one head winds while the other is unloaded, maximizing uptime.

- Control & Discharge: A sophisticated Programmable Logic Controller (PLC) manages the entire line’s speed, tension, and coordination. Finished slit coils are discharged via a coil car or tilting mandrel for handling.

Types of Slitting Lines

- Loop-Type Slitting Lines: Incorporate a looping pit between the slitter and rewinders. This allows the slitter to run at constant, optimal speed while the rewinders can start/stop for coil changes, offering superior surface quality for sensitive materials.

- Pull-Through Slitting Lines: A more compact design where the rewinder directly pulls the material through the slitter. This is highly efficient for thicker, heavier gauge materials (like hot-rolled steel) where surface marking is less critical.

Key Technical Specifications and Considerations

The design and capability of a slitting line are defined by several critical parameters:

- Master Coil Specifications: Maximum input width (e.g., 2000mm), thickness range (e.g., 0.3mm to 6.0mm), and maximum coil weight (e.g., 30 tons).

- Output Strip Specifications: Minimum and maximum slit width, number of strands, and width tolerance (often as tight as ±0.1mm).

- Line Speed: Ranges from 30 m/min for thick plate to over 600 m/min for thin, soft materials.

- Knife Setup: Drive-In systems (arbors must be removed for knife changes) vs. more advanced Quick-Change systems that allow rapid width changes and dramatically reduce downtime.

- Tension Control: Precision servo-driven systems are essential for handling delicate materials like galvanized, aluminized, or pre-painted steels without damaging the coating.

The Critical Role of Slitting Knives

The quality of the slit edge is paramount. It affects subsequent processes like roll forming, stamping, and welding. Knives are selected based on material type and thickness. Side-clearance and overlap must be meticulously set:

- Insufficient clearance causes excessive burr and knife wear.

- Excessive clearance leads to a “curly” or ragged edge.

Proper maintenance and regrinding of these high-precision tools are essential for consistent output.

Industry Applications

Slit coils are the feedstock for a vast array of manufacturing processes:

- Roll Forming Lines: For producing roofing panels, purlins, studs, and decking.

- Stampings & Blanks: For automotive parts, appliances, and electrical enclosures.

- Tube & Pipe Mills: Forming the strip that is welded into pipe.

- Strapping & Banding: Producing steel strapping for packaging and palletizing.

The steel slitting line operates as a silent enabler of industrial efficiency. Its ability to convert bulk raw material into tailored, precise feedstock with minimal waste is fundamental to just-in-time manufacturing and cost-effective production. Investing in a modern, high-precision slitting line—with features like quick-change knife systems, advanced PLC controls, and servo tensioning—is a strategic decision that directly impacts material yield, edge quality, and overall competitiveness in the metal processing industry. It is not merely a cutting machine; it is a precision tool that defines the starting point for quality in countless finished products.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)