The Roofing Sheet Machine: Precision Engineering for Shelter and Performance

In the world of modern construction, few machines hold such direct responsibility for protecting our built environment as the roofing sheet machine. This specialized equipment transforms raw metal coils into the durable, weather-resistant panels that form the primary barrier against the elements for industrial, commercial, and residential buildings globally. More than a simple former, it is a sophisticated production line that delivers consistency, efficiency, and architectural integrity.

Core Function and Product Range

A roofing sheet machine is a continuous cold roll-forming system designed to manufacture profiled metal cladding panels from coiled steel, aluminum, or other alloys. Starting with a flat metal strip, the machine progressively bends it through a series of precision rollers to create a specific, high-strength cross-sectional profile. These profiles are engineered for structural performance, water shedding, and aesthetic appeal.

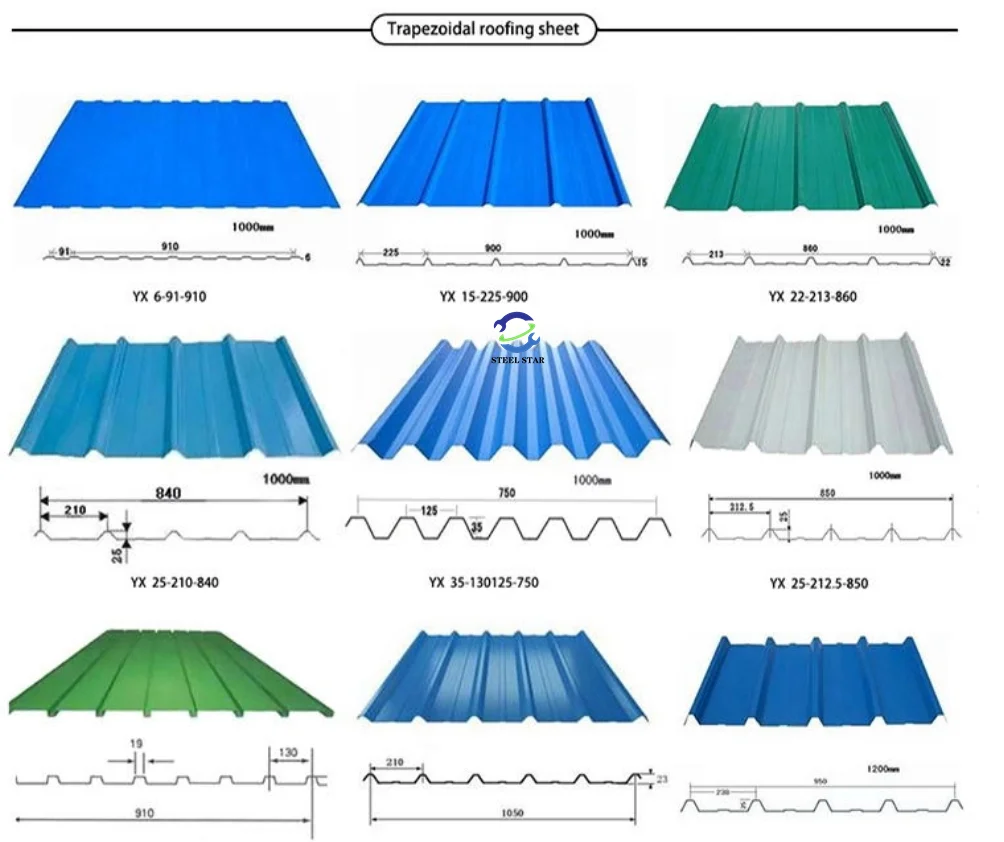

Common Output Profiles Include:

- Corrugated Sheets: The classic sinusoidal or trapezoidal wave pattern, valued for simplicity and strength.

- Standing Seam Panels: High-performance panels with raised, interlocking seams that allow for thermal movement and superior weather tightness.

- Tile Effect Profiles: Panels molded to replicate the appearance of traditional clay or concrete roof tiles.

- Trapezoidal Roof & Wall Cladding: Panels with pronounced trapezoidal ribs, offering excellent load-bearing capacity for large spans.

Anatomy of a Modern Production Line

A complete, automated roofing sheet line is a synchronized integration of several key stations:

- Loading & Feeding (Decoiler): A heavy-duty decoiler holds the master coil (often weighing several tons) and feeds it into the line under controlled tension.

- Material Preparation (Levelling & Punching):

- Leveller/Straightener: A critical component that removes any coil set or curvature, ensuring perfectly flat material enters the former.

- Pre-Punching/Notching Unit: A CNC-controlled station that punches holes for fasteners, creates notches for hips and valleys, or forms end laps before the sheet is profiled, ensuring higher accuracy and speed.

- The Heart: The Roll Forming Mill: This is a sequential bank of roll stands, each containing a set of hardened steel tooling dies. The sheet passes through these stands, with each set imparting an incremental bend until the final, complex profile is achieved. The design and precision of these rollers determine the quality of the final product.

- Cutting to Length: A high-speed, servo-controlled “flying” cut-off system—typically a shear or rotary saw—cuts the continuously moving profile to exact, pre-set lengths without stopping the production flow.

- Run-Out & Stacking: The finished sheets are conveyed to an automatic stacking station, where they are counted, aligned, and bundled for strapping and shipment.

Technological Advantages Driving Adoption

- Unmatched Production Speed & Consistency: Machines operate at linear speeds of 30-100 meters per minute, producing thousands of identical, precision-formed sheets per shift—a level of consistency impossible with manual fabrication.

- Superior Material Performance: The cold-forming process work-hardens the metal, enhancing its strength. Profiles are engineered for optimal water drainage, wind uplift resistance, and snow load capacity.

- Design Flexibility & Customization: By changing the roll tooling, a single machine can produce multiple profiles. Lines can be customized for different materials (pre-painted, galvanized, stainless steel) and can integrate embossing or special edge forms.

- Reduced Waste & Cost Efficiency: Precision manufacturing from coil stock minimizes scrap. High automation lowers labor costs and increases overall equipment effectiveness (OEE).

- Integration with Building Systems: Modern panels are designed for easy integration with insulation, solar PV mounting systems, and architectural features.

Critical Considerations for Selection

Investing in a roofing sheet machine requires careful analysis of:

- Profile Portfolio: The range of cross-sections the machine can produce.

- Material Specifications: Supported thickness (gauge), width, yield strength, and coating types.

- Line Speed & Automation Level: Desired output capacity and degree of operator involvement.

- Control System: Modern PLC and HMI interfaces for storing recipes, monitoring diagnostics, and ensuring repeatability.

- Tooling Quality & Support: High-chrome steel tooling from reputable manufacturers is essential for long-term profile accuracy and machine longevity.

The roofing sheet machine is a cornerstone of contemporary construction technology. It bridges the gap between raw material and finished building envelope, enabling the rapid, cost-effective creation of high-performance roofing systems. As architectural trends evolve and demands for energy efficiency, sustainability, and aesthetic diversity grow, these machines continue to advance—incorporating smarter controls, more flexible tooling, and capabilities for ever-more complex profiles. They are not merely fabricating metal; they are engineering the first line of defense for the structures beneath, playing an indispensable role in shaping resilient and enduring landscapes.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)