The Metal Roof Forming Machine: Engineering the Skyline

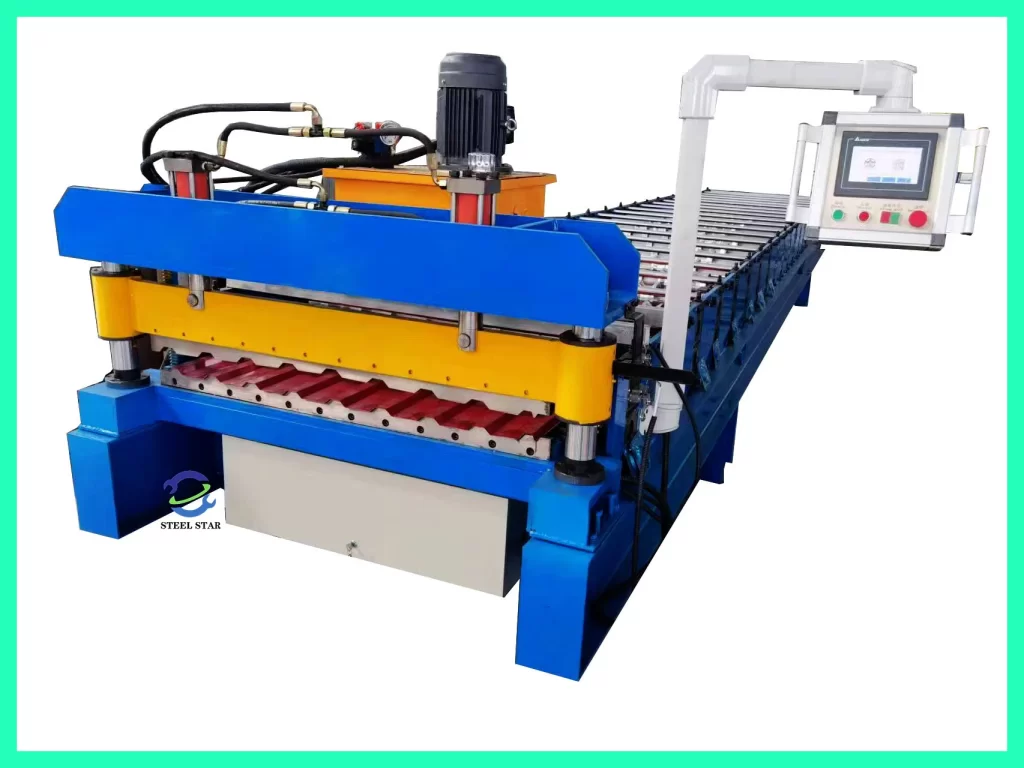

A Metal Roof Forming Machine represents the pinnacle of specialized fabrication equipment, engineered to transform flat metal coils into the high-strength, weather-resistant panels that define modern commercial, industrial, and residential architecture. Far more than a simple bender, it is a fully integrated, automated production line that merges precision mechanical engineering with advanced control systems to produce roofing components with unparalleled consistency, durability, and efficiency.

Core Function and Architectural Output

This machine is a continuous cold roll-forming system designed exclusively for manufacturing architectural metal roof and wall panels. Starting with coiled steel, aluminum, or zinc-aluminum alloy, it progressively shapes the metal through a series of precision roller dies to create specific structural profiles. These profiles are not merely aesthetic; they are scientifically engineered for optimal hydrodynamics, thermal performance, structural spanning capability, and longevity.

Key Panel Profiles Produced:

- Standing Seam Roof Panels: The gold standard for commercial roofing. These panels feature raised, mechanically seamed joints that allow for thermal expansion/contraction and provide superior resistance to water infiltration and wind uplift.

- Batten Cap/Multi-Rib Panels: Versatile panels with pronounced, evenly spaced ribs, commonly used for both roofs and walls in agricultural and industrial buildings.

- Through-Fastened Panels: Cost-effective panels where the fastener penetrates the face of the panel, secured directly to the structural framing.

- Architectural Cassette Panels: High-end, flat-profile panels with mechanically folded edges, used for sleek, contemporary façades and roofing.

- Custom Heritage Profiles: Machines can be tooled to replicate traditional shapes like tile, shake, or shingle appearances in durable metal.

Deconstructing the Integrated Production Line

A state-of-the-art machine is a symphony of synchronized subsystems:

- Coil Handling & Feeding System: Includes a heavy-duty decoiler and a precision leveller/straightener. This system ensures the metal strip enters the forming process completely flat and free of coil curvature, which is critical for final panel accuracy.

- Pre-Notching & Punching Station (CNC-Controlled): Before forming, a servo-driven punching unit precisely cuts panel ends for watertight laps, creates holes for vents or attachments, and notches for complex roof transitions (hips, valleys, ridges). Pre-forming this work is vastly more accurate than post-production modification.

- The Precision Roll Forming Mill: The machine’s core. A sequenced battery of roll stands, each equipped with CNC-machined, hardened steel roller dies, incrementally bends the metal into its final cross-section. The number of stands (often 18-30+) determines the forming smoothness and profile complexity achievable.

- Panel Cut-Off System: A high-speed, servo-electric “flying” cut-off shear or saw that operates synchronously with the moving panel. It delivers clean, burr-free cuts to exact lengths (up to 30 meters or more) without stopping the production line.

- Automatic Stacking & Handling: Finished panels are gently conveyed and automatically stacked in pre-determined bundles, often with protective interleaving, ready for strapping and direct shipment to the job site.

The Compelling Advantages: Why Metal Forming Machines Dominate

- Architectural-Grade Precision & Consistency: Every panel is identical, ensuring seamless installation, perfect alignment, and a flawless visual appearance—imperative for large-scale projects.

- Unmatched Production Throughput: Capable of producing paneling for an entire warehouse or large commercial roof in a single day, dramatically accelerating construction timelines.

- Superior Structural Integrity: The cold-forming process enhances the metal’s yield strength. Profiles are engineered for specific load-bearing capacities, spanning purlins at wide intervals without intermediate support.

- Material Efficiency & Sustainability: Manufacturing from coil generates minimal scrap (<3%). The panels themselves are often made from recycled content and are 100% recyclable at end of life.

- Integrated Smart Manufacturing: Modern machines are driven by PLCs that store hundreds of panel profiles, automate changeovers, monitor production metrics, and can integrate directly with Building Information Modeling (BIM) data for a seamless digital workflow.

Strategic Considerations for Investment

Selecting the right machine requires a detailed analysis of:

- Profile Portfolio & Flexibility: Ability to produce both standard and custom profiles, and the time required for tooling changeovers.

- Material Capability: Compatible metal types (galvanized steel, Galvalume®, aluminum, stainless steel), thickness range (e.g., 0.4mm to 1.2mm), and protective coating requirements (pre-painted, PVC).

- Production Capacity: Maximum line speed (e.g., 40-100 meters per minute), cutting accuracy, and overall system reliability for 24/7 operation.

- Control System & Automation: User-friendly interface, diagnostic capabilities, and potential for integration with factory automation networks.

- Tooling Quality & Support: The durability and precision of the roller dies, and the manufacturer’s commitment to technical support and spare parts availability.

The Metal Roof Forming Machine is more than industrial equipment; it is an enabling technology for modern architecture. It allows designers to specify long-lasting, energy-efficient, and visually striking metal roofing systems with the confidence that they can be produced and installed with precision. By turning raw metal into high-performance building envelopes, these machines play a fundamental role in constructing durable, sustainable, and aesthetically ambitious structures. As building science advances, so too will these machines, evolving to form smarter, more efficient, and more beautiful roofs that shelter our world for generations.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)